Edible oil refining facts for kids

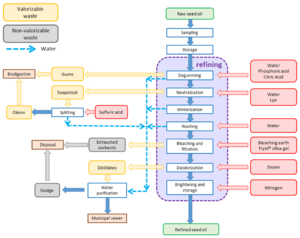

Edible oil refining is a series of steps that turn raw vegetable oil into the clear, tasty cooking oil you use every day.

Raw oil, which comes from seeds (like sunflower or soybean) after they are pressed or treated with solvents, contains many things besides just oil. It has things like fatty acids, phospholipids (gums), waxes, and other bits that can make the oil look cloudy, smell bad, or taste off. To make it good for cooking, all these extra parts need to be removed.

How is Oil Refined?

There are several important steps to clean and purify raw vegetable oil. Each step removes different unwanted parts.

What is Degumming?

Raw vegetable oil often contains substances called lecithins and phospholipids. These are often called "gums" because they can make the oil thick and sticky, like a gum. Removing these gums is called degumming. If these gums stay in the oil, they can make it too thick, which causes problems in later cleaning steps.

Not all raw oils have a lot of gums. For example, soybean and rapeseed oils have many gums, so degumming is a very important step for them. Sunflower oil has fewer gums. Because of these differences, there are a few ways to degum oil.

Dry Degumming

This method is used when there are only a few gums in the oil, like in coconut or palm oil. The raw oil is mixed with a weak acid solution, like citric acid. This acid helps to grab onto the metals and phospholipids (gums). After this, the oil usually goes straight to the bleaching step.

Soft Degumming

In this process, the raw oil is treated with a water solution that contains a special chemical called a chelating agent. This agent is very good at grabbing onto metals and phospholipids. It can remove more than 90% of the phosphorus content, which is a key part of the gums, especially in oils like rapeseed oil.

Total Degumming Process

This is a traditional method. First, the raw oil is treated with acidic water. Then, it's treated with a base (like a mild alkali). This helps to separate the gums from the oil.

Membrane Degumming

This method uses a special filter, like a very fine sieve, to separate the gums. Gums can form tiny balls called micelles, and this process filters them out. It can also remove other impurities, which helps reduce waste and energy needed later. However, it sometimes needs a chemical called hexane, and if it doesn't use it, the process can be very slow for large amounts of oil.

Enzymatic Degumming

In this process, special proteins called enzymes are added to the raw oil. These enzymes break down the phospholipids (gums). This method is good because it doesn't need high temperatures or strong acids. However, enzymes can be expensive, and separating them from the oil can be tricky.

Why Neutralize the Oil?

After degumming, the oil still has "free fatty acids." These are tiny parts of the oil that can make it taste bitter or spoil faster. Neutralization is about removing these fatty acids.

For some oils, like palm or coconut oil, which have shorter fatty acids, steam is used to strip them away. For most other oils, a dilute solution of sodium hydroxide (a mild base) is added. This turns the fatty acids into "soaps." These soaps are then separated from the oil using hot water. The leftover soap mixture is called "soapstock."

Other Ways to Neutralize

Scientists have tried other ways to remove free fatty acids to reduce waste and energy. For example, some membrane degumming methods can also remove some fatty acids. Another idea was to turn the fatty acids back into useful oil using glycerol, but these methods haven't been as good as the traditional neutralization process.

What is Winterization or Dewaxing?

Winterization, also called dewaxing, is a step where waxes and other tiny particles are removed from the oil. If these are left in, they can make the oil look cloudy, especially when it's cold. This is why it's called "winterization" – it makes sure the oil stays clear even in cold weather.

In this process, the oil is slowly cooled down while being gently stirred. As it cools, the waxes and other high-melting substances turn into tiny solid crystals. These solid bits are then separated from the clear oil using methods like filtering or spinning the oil very fast (centrifugation).

Because different oils have different waxes, there are many ways to do winterization. They might use different temperatures, cooling times, or even add special substances to help the waxes crystallize better.

How is Oil Bleached and Filtered?

Raw oil has natural colors, like green from chlorophyll or orange from carotenoids. These colors can affect the final oil's look and how it behaves during storage. Bleaching removes these colors.

This process uses a special type of clay called "bleaching earth." This clay is like a sponge that absorbs the oil's colors and any remaining metals. The oil is mixed with a small amount of this clay. Then, it's heated and a vacuum is applied. This helps the clay absorb the colors and also breaks down any harmful peroxides in the oil. After mixing, the oil is passed through a filter press, which separates the clean oil from the clay. Sometimes, silica is also used to help clean the oil and remove metals.

What is Deodorization?

Even after all these steps, the oil might still have some faint, unwanted smells or flavors. Deodorization is the final step to remove them.

In this process, the oil is heated to a very high temperature (around 270°C) and hot steam is blown through it. This steam strips away any remaining fatty acids, sterols, and other tiny substances that cause bad odors or flavors. If the oil doesn't have many bad smells, a lower temperature can be used, especially if a vacuum is applied. This step ensures the oil is neutral in smell and taste.

What is Polishing?

As a very last step before the oil is stored, it goes through another filtration. This is like a final polish to catch any tiny impurities that might still be floating around. It makes sure the oil looks perfectly clear and sparkling.

What Happens to the Waste?

Making edible oil creates some waste products. But in recent years, scientists have found ways to use some of these wastes, turning them into new useful things. This idea is part of a "circular economy," where waste is reused instead of thrown away.

Gums

The gums removed during degumming can actually be useful! They are often cleaned and used as "emulsifiers." Emulsifiers help mix oil and water, like in salad dressings. If the gums aren't valuable enough for this, they can be used in a process called "bio-digestion" to create energy.

Scientists have also found ways to separate different types of phospholipids from the gum waste and turn them into other interesting chemicals using enzymes.

Soapstock

Soapstock is the leftover mixture from the neutralization step. It contains water, soaps (from the fatty acids), and some leftover oil. It's usually treated to recover some oil and then sent for bio-digestion to produce energy.

Recently, researchers have found ways to take specific fatty acids from soapstock and turn them into other valuable chemicals, like those used in flavors or other industrial products.

Exhausted Sorbents

After bleaching, the used bleaching earth is called "exhausted sorbent." This waste still contains some oil (about 30-40% of its weight) and can even catch fire easily, so it needs careful disposal. Because of this, people are trying to find ways to clean and reuse the bleaching earth or to recover the oil from it to make things like biodiesel.

Winterization Oil Cake

The solid waste from winterization is called "winterization oil cake" or "filter cake." It's a mix of about half oil and half waxes. For example, in sunflower oil, these waxes are long chains of carbon atoms. This cake is usually thrown away. However, new research shows that these waxes can be used with sugar and special yeasts to create useful substances called "surfactants," which are used in soaps and detergents.

| Janet Taylor Pickett |

| Synthia Saint James |

| Howardena Pindell |

| Faith Ringgold |