Fibre-reinforced polymer facts for kids

A fibre-reinforced polymer (often called FRP) is a super strong and lightweight material. Think of it like a special sandwich! It's made from tiny, strong threads called fibres, which are mixed into a special kind of plastic called a polymer. This mix makes the material much stronger than the plastic or fibres would be on their own.

Contents

What are Fibre-Reinforced Polymers?

FRPs are a type of composite material. This means they are made by combining two or more different materials to create a new material with better properties. In FRPs, the strong fibres are spread throughout the plastic, which acts like a glue or "matrix" holding everything together. This design makes FRPs incredibly strong and stiff, but also very light.

What are the Fibres Made Of?

The fibres are the part that gives FRPs their amazing strength. They are usually very thin threads, almost like hair. Common types of fibres used include:

- Fibreglass: These are tiny threads of glass. They are strong and affordable.

- Carbon: These fibres are made from carbon atoms. They are super strong and very light, often used in high-performance items.

- Aramid: These are synthetic fibres known for being very tough and resistant to heat and impact. A well-known aramid fibre is Kevlar.

What are the Plastics Made Of?

The plastic part of an FRP is called the polymer matrix. It holds the fibres in place and helps transfer the forces between them. Once these plastics harden, they usually can't be melted and reshaped again. Common types of polymers used are:

- Epoxy: A very strong and durable plastic often used in high-performance FRPs.

- Vinylester: A tough plastic that resists water and chemicals well.

- Polyester: A common and versatile plastic, often used in fibreglass products.

Where are FRPs Used?

Because they are so strong, light, and durable, FRPs are used in many different places. They help make things lighter and more fuel-efficient, or stronger and longer-lasting.

- Aerospace: Airplanes and spacecraft use FRPs to reduce weight, which saves fuel and allows them to carry more.

- Automobile: Cars, trucks, and even race cars use FRP parts to make them lighter, faster, and more fuel-efficient.

- Marine: Boats, yachts, and other marine vessels often have hulls made from FRPs because they are strong and resist water damage.

- Construction: You can find FRPs in bridges, buildings, and other structures where extra strength and durability are needed. They can also be used to strengthen old concrete structures.

Images for kids

See also

In Spanish: Plásticos reforzados con fibras para niños

In Spanish: Plásticos reforzados con fibras para niños

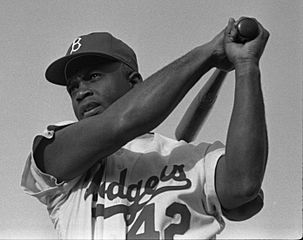

| Jackie Robinson |

| Jack Johnson |

| Althea Gibson |

| Arthur Ashe |

| Muhammad Ali |