Galvanizing facts for kids

Galvanizing is a special way to protect metal, usually iron or steel, from rusting. It involves covering the metal with a thin layer of another metal, most often zinc. This zinc layer acts like a shield, stopping the iron underneath from getting damaged by corrosion, which is what we call rusting.

Contents

Why Do We Galvanize Metal?

Iron and steel are very useful, but they can rust when exposed to air and water. Rusting makes the metal weak and can eventually destroy it. Galvanizing helps prevent this. The zinc coating protects the iron in two main ways:

- Barrier Protection: The zinc layer creates a physical barrier. It stops water and oxygen from reaching the iron. This is like putting a raincoat on the metal.

- Sacrificial Protection: Zinc is more "reactive" than iron. This means that if the zinc coating gets scratched, the zinc will still corrode (rust) instead of the iron. The zinc "sacrifices" itself to save the iron. This protection continues even if the zinc layer is slightly damaged.

This process makes metal last much longer, which is why you see galvanized metal used in many places, like fences, streetlights, and car parts.

How Is Galvanizing Done?

There are a few ways to galvanize metal, but the two most common are hot-dip galvanizing and electro-galvanizing.

Hot-Dip Galvanizing

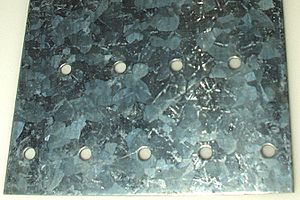

This is the most common method. In hot-dip galvanizing, the iron or steel object is cleaned very well. Then, it is dipped into a large tank filled with melted, liquid zinc. The zinc is very hot, usually around 450°C (840°F). When the object is pulled out, the zinc cools and forms a strong, thick coating.

- Pros: This method creates a very thick and durable zinc layer. It offers excellent long-term protection against rust.

- Cons: The surface might not look perfectly smooth or shiny. It can have a slightly rough or crystalline appearance.

Electro-Galvanizing

Electro-galvanizing uses a process called electroplating. The metal object is placed in a special liquid containing zinc ions. Electricity is then passed through the liquid. This causes the zinc to stick to the surface of the object in a very thin, even layer.

- Pros: This method creates a very smooth and shiny finish. It's often used when appearance is important.

- Cons: The zinc layer is much thinner than with hot-dip galvanizing. This means it might not last as long, especially in harsh conditions.

What Happens When Galvanized Metal Ages?

Over time, the zinc coating slowly corrodes away as it protects the iron. Once all the zinc is gone, the iron underneath will start to rust. However, because of the zinc's protection, this takes a very long time, often many decades.

Related pages

Images for kids

See also

In Spanish: Cincado para niños

In Spanish: Cincado para niños

| William L. Dawson |

| W. E. B. Du Bois |

| Harry Belafonte |