Electroplating facts for kids

Electroplating is a cool process that puts a thin layer of one metal onto an object made of another metal. Think of it like giving an object a special metallic "skin"! This is done using electricity. It's often used to make things look shiny and pretty, like gold jewelry, or to protect them from getting rusty, like car parts. The metal layer is usually very thin but strong.

Contents

How Does Electroplating Work?

To electroplate something, you need a few things:

- The object you want to coat (this is called the workpiece).

- A piece of the metal you want to use for the coating.

- A special liquid called a solution that contains tiny bits (ions) of the coating metal.

Both the object and the metal piece are placed into this solution. Then, an electric current is passed through them. The electricity makes the metal from the solution stick to the object, forming a smooth, even layer. It's like magic, but it's really science!

What Changes with Electroplating?

Electroplating can change an object in many ways:

- Chemical changes: For example, putting a layer of nickel on something can stop it from rusting.

- Physical changes: The object might look different, like becoming shinier or changing color.

- Mechanical changes: The surface of the object can become harder or stronger, which is useful for tools or machine parts.

For instance, a layer of chromium makes car parts look great and stops them from corroding. It's also why many gas burners in kitchens are shiny!

A Quick Look at History

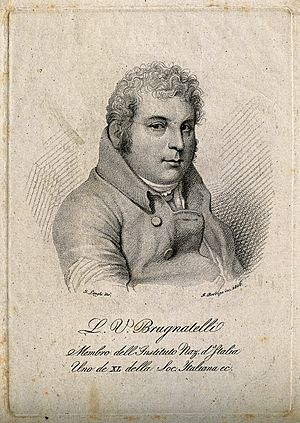

The idea of modern electroplating started way back in 1805 with an Italian chemist named Luigi Valentino Brugnatelli. He used a new invention called the voltaic pile (an early battery) to do the first electroplating experiments. However, his discoveries weren't widely known for about 30 years.

By 1839, scientists in Britain and Russia independently figured out similar ways to coat metals. In Russia, a scientist named Boris Jacobi not only rediscovered electroplating but also developed ways to create copies of objects and even sculptures using this method! Some huge sculptures on St. Isaac's Cathedral in Saint Petersburg and the golden dome of the Cathedral of Christ the Saviour in Moscow were made using this technique.

Soon after, in England, John Wright found a good chemical solution for gold and silver plating. His friends, George Elkington and Henry Elkington, got the first patents for electroplating in 1840. They started the electroplating industry in Birmingham, England, and it quickly spread worldwide. The Woolrich Electrical Generator from 1844, which you can see in the Thinktank, Birmingham Science Museum, was one of the first electric generators used in this industry!

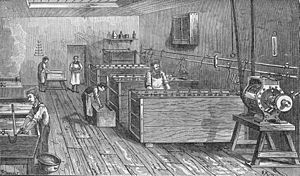

As people learned more about electrochemistry, many other types of electroplating were developed. By the 1850s, people were electroplating with nickel, brass, tin, and zinc. The equipment also got bigger and better, allowing many large objects to be plated at once.

The invention of powerful electric generators in the late 1800s really boosted the plating industry. Now, large machine parts and car parts could be plated in huge amounts, making them last longer and look better.

Even during the World Wars, electroplating continued to improve, with new processes like hard chromium plating and bronze alloy plating being developed. Equipment went from simple wooden tanks to automated machines that could process thousands of kilograms of parts every hour!

Even famous physicist Richard Feynman worked on electroplating! One of his first projects was figuring out how to electroplate metal onto plastic, which was a big deal at the time.

Where Is Electroplating Used?

Electroplating is used in many different industries. It's a great way to give metal objects a special coating that has properties the original metal might not have.

Here are some common uses:

- Making things look good: Many items like jewelry, cutlery, and decorative pieces are electroplated with gold, silver, or chrome to make them shiny and attractive.

- Protecting against rust: Car parts, tools, and outdoor equipment are often electroplated with zinc or chromium to prevent them from corroding and rusting.

- Improving hardness: Some machine parts are electroplated to make their surfaces harder and more resistant to wear and tear.

- Electronics: It's used in making circuit boards and other electronic components to improve how they conduct electricity.

Electroplating helps make many of the things we use every day stronger, prettier, and more durable!

Images for kids

-

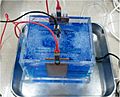

A machine that uses copper electroplating for layering PCBs.

See also

In Spanish: Galvanizado para niños

In Spanish: Galvanizado para niños

| Mary Eliza Mahoney |

| Susie King Taylor |

| Ida Gray |

| Eliza Ann Grier |