Jack (device) facts for kids

A jack is a cool tool that helps you lift very heavy things. It's like a super strong helper! You can use a jack to lift cars, parts of buildings, or other big objects.

There are two main types of jacks:

- Mechanical jacks use a special screw to push things up.

- Hydraulic jacks use liquid pressure to lift heavy loads.

The most common type you might see is a car jack. It lifts vehicles so people can fix them. Jacks are made to lift a certain amount of weight. This is called their "lifting capacity." For example, a jack might lift 1.5 tons or even many tons for industrial uses.

Contents

What's in a Name?

The word "jack" has an interesting history. It started as a common nickname for "John" around the 1200s. Later, in the 1500s, "jack" became a casual word for a regular person. Think of the saying "jack of all trades."

From there, the word "jack" began to describe tools or machines. These tools would "take the place of a man" or "save human labor." The first time "jack" was used for a lifting machine was in 1679. It described an "engine" used to move large pieces of wood.

Mechanical Jacks

Mechanical jacks use gears and screws to lift heavy items. They use a principle called mechanical advantage. This means a small force you apply can create a much larger lifting force.

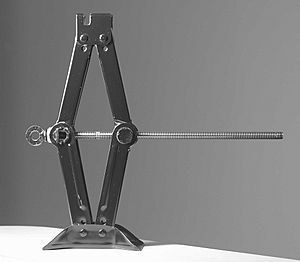

Scissor Jacks

Scissor jacks are a simple type of car jack. They use a criss-cross, or "scissor," design. You turn a handle, which spins a screw. This screw makes the scissor arms close, lifting the car. Modern scissor jacks fit into special "jack-up points" on a car's body. Older ones lifted a car by its frame or axle.

Some scissor jacks are electric. They get power from your car's 12-volt outlet. This makes them easier to use because you don't have to crank a handle.

House Jacks

A house jack is also called a screw jack. It's mainly used to lift buildings. This might be for repairs or to move a building to a new spot. Workers use many jacks together. They lift the building a little, then place wood blocks under it for support. They repeat this until the building is at the right height.

House jacks can also lift beams that have sagged. They can also help install new support beams. The top of the jack has a round pad. This pad rests under the beam and turns freely. This helps the jack lift safely and steadily.

Hydraulic Jacks

Hydraulic jacks use liquid power to lift heavy loads. In 1838, William Joseph Curtis created a design for a hydraulic jack. Later, in 1851, Richard Dudgeon got a patent for his "portable hydraulic press." This hydraulic jack was much better than the screw jacks used at the time.

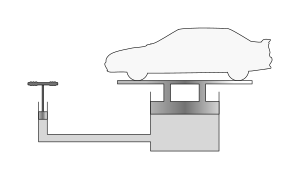

Hydraulic jacks are often used in repair shops. They are usually not carried in cars for emergencies. This is because they need careful setup. You must choose the right spot on the ground and on the vehicle. This makes sure the jack is stable when it lifts. Hydraulic jacks are also used to lift elevators in buildings.

Here's how a hydraulic jack works: 1. It uses a liquid, usually oil, because oil doesn't compress (squish). 2. A pump pushes this oil into a cylinder. 3. When a plunger pulls back, it sucks oil from a storage tank into the pump. 4. When the plunger pushes forward, it forces the oil into the main cylinder. 5. This pressure makes a lifting ram move up, lifting the heavy object.

Floor Jacks

A floor jack is also known as a "trolley jack." It has a long, flat shape when it's lowered. This lets it roll easily under a car. It has wheels and casters, so it can move as it lifts. A horizontal piston pushes a lever, which then lifts a pad. This pad stays flat as it goes up. Floor jacks can lift things quite high.

Bottle Jacks

A bottle jack looks like a bottle. It has a round body and a "neck." Inside, there's a vertical lifting ram. This ram has a support pad on top. Bottle jacks can be hydraulic or work with a screw.

In the hydraulic version, the ram comes out vertically. This happens because of hydraulic pressure from a pump. This pump can be on the jack's base or connected by a hose. Bottle jacks are best for vehicles that are already high off the ground. For lifting buildings, many bottle jacks can be linked together. This helps lift the structure evenly and with great control.

The screw version of a bottle jack works by turning a large nut. This nut spins on a threaded rod inside the jack. You usually turn this nut with a handle. Some screw bottle jacks have a second threaded rod inside. This makes them "telescopic," giving them an even greater lifting range.

Bottle jacks can lift up to 50 tons! They are used for many things, like fixing cars or house foundations. Larger ones are sometimes called "barrel jacks." They are great for short, straight-up lifts.

Pneumatic Jacks

Pneumatic jacks use compressed air to lift things.

Air Hydraulic Jacks

An air hydraulic jack is a hydraulic jack that uses compressed air. Instead of you pumping a handle, an air compressor does the work. This saves effort and can make lifting faster. Some of these jacks can still be used manually if there's no air compressor available.

Inflatable Jacks

An inflatable jack is also called a lifting bag or pneumatic lifting bag. It's an airbag that gets filled with compressed air. It lifts objects without any hydraulic parts. Once the object is lifted, the bag can be deflated and used again. These bags can lift small things like cars or even large objects like airplanes.

Rescue workers also use airbags to lift heavy objects. This helps them free people trapped underneath. There are different types of lifting bags. They work at different air pressures and have different lifting strengths. Two airbags can be stacked to lift higher. But it's important to stack them correctly. The bigger bag must be on the bottom. Also, nothing should be placed between the stacked bags. If not used correctly, stacked bags can be dangerous.

Strand Jacks

A strand jack is a special hydraulic jack. It grips steel cables. These jacks are often used together. They can lift hundreds of tons. Strand jacks are used in big engineering and construction projects.

Farm Jacks

The farm jack was invented in 1905. It's also known as a railroad jack or high lift jack. It has a steel beam with many holes along its length. A hand-operated part moves up and down the beam. Farm jacks usually come in lengths of 4, 5, or 6 feet.

Farm jacks are very useful. They can lift, pull, push, and even clamp things. This makes them popular with off-road drivers. They offer a long lifting range and are easy to carry.

Safety Rules

There are national and international rules for jacks. These rules make sure jacks are safe and work well. When someone buys a jack, they agree on which safety rules it follows. In the United States, there's a safety standard for car service equipment. This includes rules for many types of jacks.

See also

In Spanish: Gato (dispositivo) para niños

In Spanish: Gato (dispositivo) para niños

- Pallet jack

- Lift slab construction

| George Robert Carruthers |

| Patricia Bath |

| Jan Ernst Matzeliger |

| Alexander Miles |