Kanban facts for kids

Kanban (pronounced KAHN-bahn) is a Japanese word meaning "signboard" or "billboard." It's a special system used in factories to make things more efficiently. This method is also known as "just-in-time manufacturing."

Taiichi Ohno, an engineer at Toyota, created Kanban to make factories work better. The system gets its name from the cards used to track what's being made. In the car industry, it's sometimes called the Toyota nameplate system.

One main goal of Kanban is to stop factories from making too much stuff. It sets a limit on how many items can be "work in process" (WIP). WIP means products that are still being made. By limiting WIP, Kanban helps avoid having too many unfinished items. If the limit is reached, it shows there might be a problem that needs fixing.

Contents

How Kanban Started

The idea for Kanban came from a simple system used in British factories during Second World War. They used a "two-bin system" to make Spitfires. When one bin of parts was empty, it signaled that more parts were needed.

In the late 1940s, Toyota looked at how supermarkets worked. They noticed that customers only took what they needed, when they needed it. Supermarkets also only stocked what they expected to sell. This made Toyota think of each step in a factory as a "customer" of the step before it.

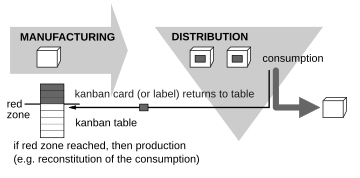

Kanban helps factories make sure they only have enough materials for what they need right now. When a material is used up, a signal is sent to the supplier to deliver more. This signal helps everyone involved, from the supplier to the buyer, see what's happening.

This system uses the customer's demand to control how much is produced. If customers want more, the factory makes more. If they want less, the factory makes less. Toyota first used this idea in their main factory in 1953.

How Kanban Works

Some factories "push" products through production based on what they guess customers will want. Kanban is different. It's a "pull" system. This means products are only made when a customer orders them. Production is based on real customer demand.

If it takes a long time to get supplies, or if it's hard to guess what customers will want, Kanban is very helpful. It sends a signal right away through the supply chain when something is needed. This helps keep the amount of stored items (inventory) smaller and better managed.

Taiichi Ohno said that for Kanban to work well, everyone must follow strict rules. Toyota, for example, has six simple rules. They constantly check these rules to make sure the system works as it should.

Toyota's Six Rules for Kanban

Toyota created these six rules for using Kanban:

- Each step in making a product asks for more supplies when it uses up what it has.

- Each step makes products based on the amount and order of the requests it gets.

- Nothing is made or moved without a request.

- The request card for an item is always kept with that item.

- Factory steps must not send out broken items. This helps make sure the final products are perfect.

- Limiting the number of requests waiting makes the process more sensitive. It also helps show where things are not working well.

Kanban Cards

Kanban cards are a very important part of the system. They are like messages that tell workers to move materials inside the factory. Or they tell an outside supplier to send more materials to the factory. A Kanban card signals that a product, part, or material is running low.

When a card is received, it triggers a request for more of that item. So, when something is used up, it creates a demand for more production. Kanban cards help make sure that production is driven by real demand, not just guesses.

Many people who support "lean production" believe that demand-driven systems are better. They think these systems lead to faster production and lower amounts of stored items. This helps companies be more competitive.

Today, many factories use electronic systems to send Kanban signals. This means fewer physical cards are used. But you can still find Kanban cards in many modern factories. Some software systems use emails to send Kanban signals to suppliers. When a part runs low, a signal is sent, and a new order is placed. The supplier then sends the material within a set time.

Kanban cards simply show that more materials are needed. For example, a red card in an empty parts cart means that more parts are needed.

Three-Bin System Example

A simple way to use Kanban is the "three-bin system." This is used for parts that are bought from outside suppliers.

- One bin is on the factory floor where parts are used.

- One bin is in the factory's storage area.

- One bin is at the supplier's location.

Each bin usually has a removable card with product details. This is the classic Kanban card.

When the bin on the factory floor becomes empty, the empty bin and its card go back to the factory store. The factory store then replaces the empty bin on the floor with a full bin from its storage. This full bin also has a Kanban card.

Next, the factory store sends the empty bin with its card to the supplier. The supplier then delivers a full bin of parts, with its card, back to the factory store. The supplier keeps the empty bin. This way, the factory never runs out of parts. It's a closed loop that provides exactly what's needed, with just one extra bin to handle any delays. This "spare" bin helps with unexpected changes in supply or use.

Many factories that use Kanban also use a colored board system called a heijunka box.

Electronic Kanban

Many factories now use electronic Kanban (or e-Kanban) systems. These systems help avoid common problems like typing errors or lost cards. E-Kanban systems can connect with other factory computer systems, like enterprise resource planning (ERP) systems. This allows for real-time signals across the supply chain and better visibility.

E-Kanban uses technology to signal when materials need to move. Instead of physical cards, it uses barcodes and electronic messages like email.

In a typical e-Kanban system, items have barcodes. Workers scan these barcodes at different steps of making a product. This signals that the item has been used. The scans send messages to internal or external stores to restock products. E-Kanban often uses the internet to send messages to suppliers. It also lets people see inventory levels in real-time through a special website.

Companies like the Ford Motor Company and Bombardier Aerospace have used e-Kanban systems to make their processes better. These systems are now very common, either as stand-alone programs or as parts of larger ERP systems.

Types of Kanban Systems

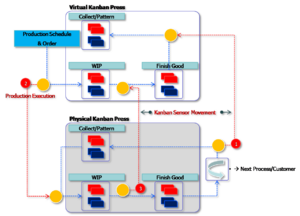

In a Kanban system, different workstations (places where work is done) talk to each other using cards. Each container of parts has a Kanban card with it. The two most important types of Kanban are:

- Production (P) Kanban: When a P-Kanban card is received, it tells a workstation to make a certain amount of products. This card stays with the containers of those products.

- Transportation (T) Kanban: A T-Kanban card gives permission to move a full container to the next workstation. This card also stays with the containers as they move.

The Kanban idea is also used in managing projects, especially in agile project management. It helps teams organize their tasks. You can see how it works in an online "agile" simulator.

Here's how Kanban is often used:

- Work is broken down into clear steps.

- Each step has two parts: a "queue" (things waiting) and "work in progress" (things being done).

- The team decides how much work each step can handle at one time.

- New work is put into the "queue" and then "pulled" into the "work in progress" section.

- If needed, work can be stopped at two steps to clear up any slowdowns.

Kanbrain

A third type of Kanban is used for training people. It's called "Kanbrain." Just like in manufacturing, this system means people learn a skill exactly when they need it. This is better than taking a course and then forgetting what they learned because they don't use it right away.

Images for kids

See also

In Spanish: Kanban para niños

In Spanish: Kanban para niños

- Just-in-time manufacturing

- Lean manufacturing

- Supply chain management

- Visual control

| Misty Copeland |

| Raven Wilkinson |

| Debra Austin |

| Aesha Ash |