Microplate facts for kids

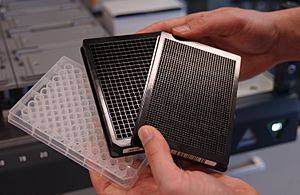

A microplate is like a flat tray with many small "wells" or tiny test tubes. Scientists and doctors use these plates in laboratories for experiments and medical tests. They are a very important tool!

One common use for microplates is in a test called ELISA (enzyme-linked immunosorbent assay). This test helps doctors diagnose many diseases in people and animals.

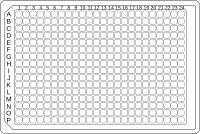

Microplates usually have a certain number of wells, like 6, 12, 24, 48, 96, 384, or 1536. These wells are set up in a rectangular pattern. Some special microplates can even have thousands of wells!

Each well on a microplate can hold a very small amount of liquid, from tiny drops to a few milliliters. They can also store dry powders or hold small glass tubes. The wells can be round or square. Square wells with tight-fitting caps are good for storing chemicals for a long time.

Microplates can be stored in very cold places. They can also be heated to make liquids dry faster. Sometimes, they are sealed with foil or clear film to protect what's inside.

Since the 1980s, many types of microplates have been made. Today, there are microplates for almost every kind of science experiment. They are used for filtering, separating, storing, mixing, growing cells, and finding out if medicines work against germs.

Scientists often grow live cells in microplates. For this, the plates are specially treated. Their surfaces are changed to be more "hydrophilic" (water-attracting). This helps cells stick and grow better, as the original plastic surface is often "hydrophobic" (water-repelling).

Many companies have made robots just to work with microplates. These robots can move liquids into and out of the wells. Other robots move the plates between different machines. There are also robots that stack plates, store them, wash them, or seal them. Some machines are even designed to keep plates at a steady temperature during tests.

Special machines called plate readers can detect what's happening inside the wells. They can find out if a chemical reaction happened or if cells are growing. There are even readers that check if wells are empty, full, or have solid bits in them.

Contents

How Microplates are Made

Microplates are usually made by a process called injection molding. This is like pouring melted plastic into a mold to create the shape. Different plastics are used depending on what the plate needs to do. For example, some plastics are better for high temperatures or for resisting certain chemicals.

Here are some common materials used:

- Polystyrene (PS) is very common. It's used for plates where light needs to pass through for measurements. It can be made white for some tests or black for others. But, it doesn't work well with some strong chemicals.

- Polypropylene (PP) is used for plates that need to handle big temperature changes, like storing samples in very cold freezers or heating them up. It's great for storing chemicals and resists many strong chemicals.

- Cyclo-olefins (COC) are used for plates that let special light (near-ultraviolet) pass through. This is useful for some protein tests. However, it doesn't resist strong chemicals well and can't handle very high temperatures.

- Polycarbonate (PC) is cheap and easy to mold. It's often used for disposable plates in polymerase chain reaction (PCR) tests, which help make copies of DNA.

- Glass or quartz are sometimes used for very special tests. They are more expensive but can resist very strong chemicals or allow certain types of light (ultraviolet C) to pass through.

Some microplates are made from several parts put together. For example, some plates used for ELISA tests are made of 12 separate strips, each with eight wells. This lets people use only part of a plate if they don't need all 96 wells.

Different Sizes and Shapes

Microplates are made with a standard size for their base, so they fit into machines. But they come in many different formats, materials, heights, and well shapes.

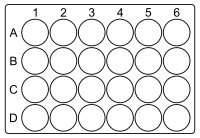

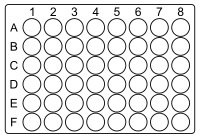

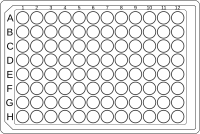

Here are some common well numbers and how much liquid they can hold:

| Wells | Volume (mL) |

|

|---|---|---|

| Number | Arrangement | |

| 6 | 2×3 | 2 – 5 |

| 12 | 3×4 | 2 – 4 |

| 24 | 4×6 | 0.5 – 3 |

| 48 | 6×8 | 0.5 – 1.5 |

| 96 | 8×12 | 0.1 – 0.3 |

| 384 | 16×24 | 0.03 – 0.1 |

| 1536 | 32×48 | 0.005 – 0.015 |

| 3456 | 48×72 | 0.001 – 0.005 |

There are also less common plates with 192 or 768 wells.

Why Standards are Important

To make sure microplates from different companies work with different machines, groups like the Society for Biomolecular Sciences (now part of SLAS) created standards. These standards help make sure that:

- The overall size of the plate (its "footprint") is the same.

- The position of the wells is the same, especially for 96, 384, and 1536-well plates. This means a robot can always find the wells.

For example, 96-well plates have wells spaced 9 mm apart. 384-well plates have wells spaced 4.5 mm apart. This careful spacing means machines can easily switch between different plate types.

However, not everything is standardized. The exact shape and size of the well opening are not always the same. This can sometimes make it tricky to find matching lids or caps for plates from different makers.

Wells can have different shapes at the bottom:

- F-Bottom: Flat bottom, good for reading light through the well.

- V-Bottom: V-shaped bottom, good for getting out very small amounts of liquid.

- U-Bottom: U-shaped bottom, also good for getting out small amounts of liquid.

- C-Bottom: A flat bottom with slightly rounded edges.

The standard height for a microplate is about 14.35 mm. But some plates are "deep well" plates, which are much taller (often around 44 mm). These are sometimes called "blocks" and can hold more liquid.

There are also "reservoir plates." These plates have columns of wells that are joined together to make bigger wells. This is useful for machines that need to add liquid to many wells at once.

Microplates used for PCR tests have thinner walls to help heat move through them better. They also come in different "skirt" types (full, half, or no skirt), which refers to the plastic around the bottom edge.

History of Microplates

The very first microplate was made in 1951 by a Hungarian scientist, Dr. Gyula Takátsy. He carved 72 small wells into a plastic material called Lucite. Later, in 1962, Dr. John Louis Sever improved this design and made a 96-well plate.

But microplates didn't become widely used until the late 1980s. By 1990, more than 15 companies were making many different kinds of microplates. It's estimated that 125 million microplates were used in the year 2000 alone! The name "Microtiter" is a registered trademark.

In 1996, a group called the Society for Biomolecular Screening (SBS) started working to create standard rules for microplates. These rules were published in 2003. They help make sure that microplates and the machines that use them can work together, even if they are made by different companies. This is very important for labs that use laboratory automation (robots).

Later, in 2010, the SBS joined with another group to form the Society for Laboratory Automation and Screening (SLAS). Now, the microplate standards are known as ANSI SLAS standards.

See also

In Spanish: Placa microtituladora para niños

In Spanish: Placa microtituladora para niños

- Picotiter plate

- Nanotiter plate