Newmarket Brickworks Chimney facts for kids

Quick facts for kids Newmarket Brickworks Chimney |

|

|---|---|

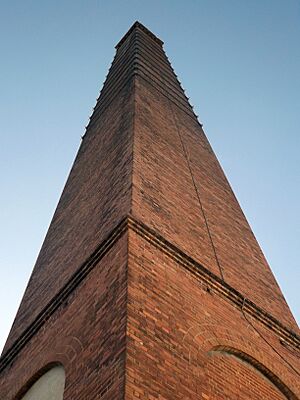

Structure in 2015

|

|

| Location | 117 Mina Parade, Alderley, City of Brisbane, Queensland, Australia |

| Design period | 1900 - 1914 (early 20th century) |

| Built | 1912 |

| Official name: Newmarket Brickworks Chimney, Hoffman Stack | |

| Type | state heritage (built) |

| Designated | 24 March 2000 |

| Reference no. | 601357 |

| Significant period | 1912 (fabric) 1912-1987 (historical) |

| Lua error in Module:Location_map at line 420: attempt to index field 'wikibase' (a nil value). | |

The Newmarket Brickworks Chimney is a very old and important chimney in Alderley, Queensland, Australia. It was built in 1912 and was once part of a large brick-making factory. This factory was known as the Brisbane Brick and Builders Supply Company Ltd, or simply "Brisbane Brick." The chimney is also sometimes called the Hoffman Stack. Because of its history and unique design, it was added to the Queensland Heritage Register on March 24, 2000.

The Story of the Chimney

The Newmarket Brickworks Chimney was built in 1912. It was a key part of a brand new factory. This factory was started by Aleck Anderson, an experienced builder. His company aimed to make high-quality bricks for buildings.

Brickmaking in Queensland

People have been making bricks in Queensland since the 1820s. The first bricks were made in Redcliffe. Later, bricks were made in Brisbane Town. Local clay was used for these early bricks.

A big fire in Queen Street in 1864 changed things. After the fire, local rules encouraged using bricks for building. This was safer than timber. However, bricks were expensive, so they were mostly used for big public buildings.

The Challenge of Bricks

Queensland had lots of timber, so building with wood was common. This made it hard for brick factories to grow. In 1911, Aleck Anderson and other builders started Brisbane Brick. They wanted to make good bricks that were hard to find.

Their factory used a special method called the Hoffman method. The main oven, or kiln, was called the "Hoffman Kiln."

The Hoffman Method

The Hoffman method was invented by Friedrich Hoffman in 1859. It was a clever way to make bricks faster. This method allowed bricks to be dried and fired at the same time. It was called "continuous firing."

Imagine many rooms, or chambers. In one room, new, wet bricks were stacked. Other rooms had bricks getting drier. In another, bricks were just starting to bake. Some rooms were fully baking bricks. Others were cooling down. One room might be empty, ready for new bricks. This made brick production much more efficient.

By the late 1800s, Hoffman's method was used in Australia. It meant that good quality bricks could be made in large numbers. They were also much cheaper than handmade bricks.

Ups and Downs of Brisbane Brick

Brisbane Brick first appeared in business listings in 1912-1913. Because timber was so popular, the demand for bricks sometimes dropped. Factories would often close for months or even years.

After one closure, Brisbane Brick raised money to update its factory. They wanted to make it more modern. They kept making bricks until World War II started.

During the war, the factory was used by the Defence Department. They stored clothes, boots, and other supplies there. The company's engineers even helped fix ships. World War II made it very difficult for brick factories. Brisbane Brick's Newmarket factory had to close.

After the War

After the war, brick factories faced new challenges. Prices were controlled, which slowed down updates. When price controls were lifted, companies like Brisbane Brick worked hard to catch up. They improved their factories and how they made bricks.

Soon, there was a huge demand for bricks for new homes and buildings. Factories struggled to make enough! In 1961, Brisbane Brick opened a new factory called Strathpine Bricks Pty Ltd. This new factory used modern "tunnel kiln" equipment. It was designed to look very different from old factories with tall chimneys.

The Chimney Stands Alone

Later, another company, PGH, continued to run the Newmarket brickworks. By 1985, the factory site was very large. In 1987, most of the brickworks were taken down. This included the Hoffman kiln and other buildings. The land was then divided up for new uses.

However, the tall chimney was saved! It was kept because it was a rare example of a brick chimney from that time. Today, the area around it has been redeveloped. The chimney now stands alone, a reminder of its past.

What the Chimney Looks Like

The brick chimney is located on Mina Parade. It stands about 40 meters (130 feet) from the road. The chimney is very tall, reaching about 55 meters (180 feet) high. This makes it a very noticeable landmark in the area.

The bottom part of the chimney is square, about 4.7 meters (15 feet) long on each side. It rises about 10 meters (33 feet) before getting narrower. It tapers to about 3 meters (10 feet) square at the top.

The bottom section has several arched shapes. These look like decorations. One of these arches, on the side facing Mina Parade, has been filled in with concrete. Near the very top, there are several bands of bricks. These also add to its decorative look.

A metal strip runs down the eastern side of the chimney. This strip helps protect it from lightning strikes. There are also metal bands wrapped around the upper part of the chimney.

The chimney is in pretty good shape. However, there is some dampness on the eastern side. There is also a crack on the northern side, about 7 meters (23 feet) from the bottom. Some of the mortar between the bricks is breaking away.

The area where the brickworks used to be is now completely changed. The chimney stands by itself in its own space.

Why the Chimney is Important

The Newmarket Brickworks Chimney is listed on the Queensland Heritage Register. This means it's a very important historical site. It meets several special requirements:

Showing Queensland's History

The chimney is a rare example of the brick-making industry in Brisbane. It shows how hard brick makers worked in the early 1900s. Back then, most buildings in Queensland were made of timber.

The chimney is also linked to the Brisbane Brick and Builders Supply Company Ltd. This company made bricks for many important buildings. These included buildings at the University of Queensland and the MLC building in Brisbane.

A Rare Part of Our Heritage

This chimney is special because it's one of the few remaining examples of a brick factory chimney in Brisbane. When the rest of the Newmarket Brickworks was taken down in 1987, the chimney was saved. It was kept because it was so rare and important.

A Local Landmark

The Newmarket Brickworks Chimney is over 50 meters (164 feet) tall. You can see it clearly from many nearby roads and areas. Because of its height and history, it's a well-known landmark in Brisbane. Many local people and others recognize it.

Important to the Community

The chimney is a familiar sight to many people. It has a strong connection with the local community. It's recognized as a significant part of the area's history and identity.

| Sharif Bey |

| Hale Woodruff |

| Richmond Barthé |

| Purvis Young |