Planer (metalworking) facts for kids

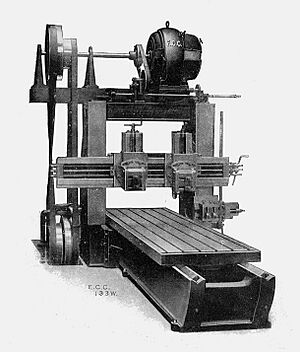

A planer is a special type of machine used to cut metal. Imagine a very strong, sharp tool that can shave off layers from a metal block! It works by moving a piece of metal back and forth under a fixed cutting tool. This tool then carefully removes bits of metal to make the surface flat or to create specific shapes.

Planers are similar to another machine called a shaper. The main difference is that with a planer, the metal piece itself moves, while with a shaper, the cutting tool does the moving. Planers are usually much larger than shapers.

Contents

What Planers Do

Planers are used for some important jobs when working with metal:

Making Flat Surfaces

- Planers are excellent at making very flat surfaces on large metal pieces.

- They can remove a lot of metal quickly and still be very accurate.

- Think of it like smoothing out a rough block of metal until it's perfectly flat.

Cutting Grooves and Shapes

- Planers can also cut special grooves, like "keyways." These are slots used to fit parts together.

- They can even cut tricky shapes inside a metal block.

- If you start with a drilled hole, a planer can cut unusual shapes with sharp corners inside it.

Making Spiral Cuts

- Even though planers usually cut in straight lines, they can also make spiral or "helical" cuts.

- This happens by spinning the metal piece at the same time it moves back and forth.

- It's a bit like how a milling machine makes spirals or how screws are made.

Why Planers Are Still Used

Today, other machines like milling machines, broaching machines, and grinding machines often do the work planers used to do. So, planers are not as common as they once were.

However, planers are still very useful for certain jobs:

- Smaller workshops that make tools and dies use them. They help fix and maintain large metal-stamping tools or plastic molding tools.

- They are also used when a very big piece of metal (like 4 feet by 8 feet or more) needs to be made perfectly square. This is especially true if a huge grinding machine or floor mill isn't available or is too expensive.

- Sometimes, an older machine that still works and has already been paid for is simply the best choice. This is why "old-fashioned" machines often stay in use for a long time in factories.

Different Types and Sizes

There are two main types of planers for metal:

- Double-housing planers: These have strong vertical supports on both sides of their long base.

- Open-side planers: These have a vertical support on only one side. This allows the metal piece to stick out beyond the machine's base, which is useful for very wide items.

Metal planers can be quite big! Their tables can range from about 30 inches by 72 inches to a massive 20 feet by 62 feet. They can weigh anywhere from around 20,000 pounds to over 1,000,000 pounds!

History of Planers

People started thinking about how to build planing machines in France around the 1750s. Then, in the late 1810s, several clever engineers in British workshops helped develop the planer into the machine tool we know today.

Some of these pioneers included James Fox, George Rennie, Matthew Murray, Joseph Clement, and Richard Roberts. It's hard to know the exact details of who invented what first. This is because the work was often kept secret by companies, and no one was writing down records for history. However, these inventors all played a part in creating these important metal-cutting machines.

| Madam C. J. Walker |

| Janet Emerson Bashen |

| Annie Turnbo Malone |

| Maggie L. Walker |