Shaper facts for kids

In the world of machining, a shaper is a special kind of machine tool. It works by moving a cutting tool in a straight line across a piece of metal. Imagine a knife slicing bread, but instead of slicing, it shaves off tiny bits of metal. This machine creates flat surfaces or grooves.

It's important not to confuse a metalworking shaper with a wood shaper. A wood shaper is a different tool used for woodworking. It has a spinning cutter and is used to shape wood, often called a spindle moulder in the UK.

A metal shaper is a bit like a metalworking planer. But there's a key difference: on a shaper, the cutting tool moves back and forth. The metal piece stays still. On a planer, the metal piece moves under the tool. The shaper's moving part, called a ram, is usually powered by a mechanical crank. Some newer shapers use hydraulic power.

Contents

How Does a Shaper Work?

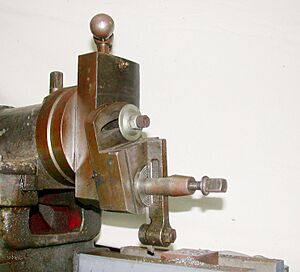

A shaper uses a single, sharp cutting tool. This tool is held firmly in a special holder on the ram. The metal piece you want to shape is held tightly in a vise or clamped to the machine's table.

The ram moves back and forth over the metal piece. The cutting tool does its work only when the ram moves forward. This is called the "cutting stroke." When the ram moves back, it's called the "return stroke," and no cutting happens. This return stroke is much faster than the cutting stroke. This saves time!

The Cutting Action

During the forward stroke, the tool shaves off a small layer of metal. After each cut, the metal piece moves a tiny bit sideways. This prepares it for the next cut. This movement is controlled by a special system called a pawl and ratchet mechanism. It makes sure the cut goes deeper each time.

Moving the Workpiece

The metal piece sits on a strong, box-shaped table. You can adjust the table's height to fit different metal pieces. The table can also move sideways under the cutting tool. This sideways movement can be done by hand or automatically by the machine.

At the front of the ram, there's a part called a tool slide. This slide holds the clapper box and the tool itself. The clapper box is designed so the tool lifts slightly on the return stroke. This prevents the tool from dragging and getting dull. The tool slide also lets you move the tool down. This makes the cut deeper with each pass. This design allows shapers to cut flat surfaces, grooves, and even gear teeth.

Different Kinds of Shapers

Shapers come in various types, but the most common is the horizontal shaper. This means the ram moves side to side. Other types include draw-cut, geared, crank, and hydraulic shapers.

There are also vertical shapers. These are often used with a rotary table. This allows them to cut curved surfaces. A vertical shaper is very similar to a slotter (or slotting machine). A slotter's cutting tool only moves straight up and down.

What Can Shapers Make?

Shapers are great for making flat, straight surfaces. But with a bit of cleverness, they can do much more! Here are some cool things shapers can create:

- Keyways: These are grooves cut into the center of things like pulleys or gears. They help parts fit together and spin without slipping.

- Dovetail slides: These are special interlocking shapes used in machine parts.

- Internal splines and gear teeth: Shapers can cut teeth inside a hole, which is tricky for other machines.

- Complex shapes: They can even make shapes that might otherwise need very advanced machines like wire EDM. For example, they can cut oddly shaped holes with sharp corners.

- Smoothing surfaces: Shapers can also be used to make a rough metal surface smooth and flat.

The History of Shapers

People started developing shapers a long time ago. Samuel Bentham worked on one between 1791 and 1793. Later, James Nasmyth is often given credit for inventing the modern shaper in 1836.

Shapers were very important in factories from the mid-1800s to the mid-1900s. Today, newer machines like milling machines and grinding machines, especially those controlled by computers (CNC), have taken over much of the work shapers used to do.

However, shapers are still useful! Their tools are simple and cheap to make. They are also strong and easy to fix. This makes them popular in smaller workshops or for making just a few parts. Many hobbyists also enjoy using old shapers or even building their own!

See also

| Valerie Thomas |

| Frederick McKinley Jones |

| George Edward Alcorn Jr. |

| Thomas Mensah |