Robert Forester Mushet facts for kids

Quick facts for kids

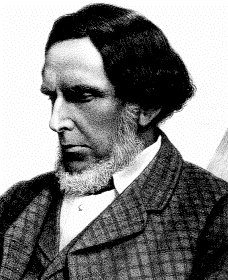

Robert Forester Mushet

|

|

|---|---|

|

|

| Born | 8 April 1811 Coleford, Gloucestershire, England

|

| Died | 29 January 1891 (aged 79) Cheltenham, England

|

| Occupation | Metallurgist |

| Known for | Developing an inexpensive way to make high quality steel, by perfecting the Bessemer Process Inventing the first commercially produced steel alloy. |

Robert Forester Mushet (born April 8, 1811, died January 29, 1891) was a clever British scientist and businessman. He was a metallurgist, which means he studied metals and how to make them better. Robert was born in Coleford, England. His father, David Mushet, was also an expert in metals, called an ironmaster.

In 1818, Robert's father built a factory called Darkhill Ironworks. Robert grew up learning about metals from his father. In 1845, he took over running Darkhill. He later moved to the Forest Steel Works in 1848. There, he did over ten thousand experiments in ten years! In 1862, he moved to the Titanic Steelworks.

Robert started using his middle name 'Forester' around 1845. He said he got the name from the Forest of Dean, where he lived.

In 1876, Robert Mushet received the Bessemer Gold Medal. This was the highest award from the Iron and Steel Institute. It showed how important his work was. Robert Mushet died on January 29, 1891, in Cheltenham. He is buried there with his wife and daughter.

Contents

Making High Quality Steel

Robert Mushet made a huge difference in how steel was made. Steel is a very strong metal used for many things, like buildings and tools.

In 1848, a friend showed Mushet a special metal from Germany. It was an alloy, meaning it was a mix of iron and manganese. Mushet realized this metal, called spiegeleisen, could be very useful for making steel.

He did many experiments with spiegeleisen. He found that adding a small amount of it made steel much easier to work with when it was hot. This was a big discovery!

Improving the Bessemer Process

In 1856, Mushet's friend, Thomas Brown, brought him a piece of steel. It had been made using a new method called the Bessemer Process. But this steel was not very good quality. Thomas asked Mushet if he could make it better.

The inventor, Henry Bessemer, had a problem. His process made steel, but it was hard to control the quality. He spent a lot of money trying to figure out how to remove impurities (unwanted stuff) from the iron. He needed to know exactly when to stop the air flow to leave just the right amount of carbon. But he couldn't find the answer.

Mushet's idea was simple and brilliant. He decided to burn off all the impurities and carbon first. Then, he would add back the right amount of carbon and manganese using his spiegeleisen. This made the steel much better. It became more malleable, meaning it could be shaped and hammered easily at high temperatures.

Mushet knew he had perfected the Bessemer process. He thought he and Bessemer would become very rich. However, Mushet did not make a fortune from his discovery. By 1866, he was very poor and sick.

His 16-year-old daughter, Mary, bravely went to London. She met Henry Bessemer and told him that his success was thanks to her father's work. Bessemer's steel process wasn't really useful without Mushet's improvements. So, Bessemer decided to pay Mushet a yearly pension of £300. This was a lot of money back then. He paid it for over 20 years, possibly to avoid legal problems.

Stronger Steel Rails

In 1857, Robert Mushet made another important invention. He was the first to create strong, long-lasting rails out of steel. Before this, railway tracks were made from cast iron, which broke easily. Mushet's steel rails helped train travel grow all over the world.

The first of Mushet's steel rails was sent to a busy train station in Derby, England. The old iron rails there had to be replaced every few months. Six years later, in 1863, Mushet's steel rail still looked perfect. About 700 trains had passed over it every day! Over 16 years, more than a million engines and tenders (parts of trains) went over that single rail.

Dozzles for Better Castings

When hot steel cools in a mold, it can form a hollow space inside, like a pipe. In 1861, Mushet invented something called a 'Dozzle'. It was a hot clay cone or sleeve. It was placed at the top of the mold and filled with molten steel. This kept a pool of hot steel that would drain down and fill any hollow spaces as the main casting cooled.

Mushet said his 'Dozzles' and other small inventions saved steelmakers millions of pounds. But he never got paid or recognized for them. Today, these 'Dozzles' are still used and are called hot tops or feeder heads.

Special Steel Alloys

In 1868, Mushet made another big step in metal science. He invented 'R Mushet's Special Steel' (RMS). This was the first true tool steel and the first air-hardening steel. Before RMS, steel tools had to be rapidly cooled in water to make them hard. But with Mushet's self-hardening steel, tools could run much faster. They could also cut harder metals than ever before.

RMS changed how machine tools were designed and how metal was worked in factories. It was the start of high speed steel, which is still used today.

See also

- Crucible steel

- Spathic iron ore

| Georgia Louise Harris Brown |

| Julian Abele |

| Norma Merrick Sklarek |

| William Sidney Pittman |