Sieve analysis facts for kids

A sieve analysis (also called a gradation test) is a way to sort materials by the size of their tiny pieces. Imagine you have a pile of sand, rocks, or even seeds. This test helps engineers and scientists figure out how much of that pile is made of small pieces, medium pieces, or large pieces.

It works by shaking the material through a stack of special screens called sieves. Each sieve has holes that are a different size. The biggest holes are at the top, and the smallest are at the bottom. This helps us understand how the material will behave when used in things like building roads or making concrete.

Contents

How a Sieve Analysis Works

A sieve analysis is usually done in a lab. You start with a sample of material, like crushed rock or sand.

First, you weigh your sample. Then, you pour it into the top sieve, which has the largest openings. Below it, there's a stack of sieves, each with smaller and smaller holes. At the very bottom, there's a pan to catch the smallest bits.

The whole stack of sieves is then placed in a machine called a mechanical shaker. This machine shakes the sieves for a set time. The shaking helps the smaller pieces fall through the holes to the sie sieves below. Larger pieces stay on the sieves where they can't fit through the holes.

After shaking, you carefully weigh the material left on each sieve. By comparing this weight to the total weight of your original sample, you can figure out what percentage of the material was stopped by each sieve. This tells you the size of the particles in your sample.

Engineers use these results to choose the right materials for different projects. For example, they might need a specific mix of particle sizes for strong concrete or smooth asphalt.

Getting Ready for the Test

Before you can do a sieve analysis, you need a good sample of the material. This sample should be mixed well and be the right size for testing. You also need to know the total weight of your sample before you start.

Understanding the Results

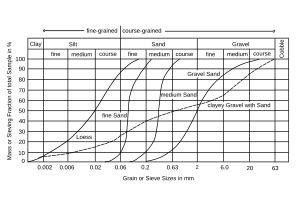

The results of a sieve analysis are often shown on a graph. This graph helps you see the particle size distribution of your material. The graph usually shows the percentage of material that passed through each sieve (on the 'y' axis) compared to the size of the sieve openings (on the 'x' axis). The sieve size scale is often logarithmic, which means it shows sizes in a special way.

To figure out the percentage of material that passed through each sieve, you first calculate the percentage that was retained (or held back) on each sieve. You do this with a simple formula:

% Retained = (Weight on Sieve / Total Weight of Sample) × 100%

Next, you find the cumulative percent retained. This means you add up the percentage of material on the current sieve and all the sieves above it.

Finally, to get the cumulative percent passing (which is what's usually plotted on the graph), you subtract the cumulative percent retained from 100%.

% Cumulative Passing = 100% - % Cumulative Retained

These numbers are then plotted on the graph. This visual helps engineers quickly understand the mix of particle sizes in the material.

Different Ways to Sieve

There are several ways to perform a sieve analysis, depending on the type of material you are testing.

Throw-Action Sieving

In this method, the sieve stack moves up and down, and also in a slight circle. This motion throws the particles upwards. While they are in the air, they spin around. When they fall back down, they might hit the sieve mesh at a different angle. If they are small enough, they will pass through. If not, they are thrown up again.

Modern machines for this method use an electromagnetic motor. This makes the shaking very precise and repeatable, which is important for getting accurate results. You can adjust how strongly and for how long the sieves shake to get the best results for different materials. This is the most common method used in labs.

Horizontal Sieving

Horizontal sieve shakers move the sieve stack in flat circles. This method is good for materials that are long, flat, or fibrous, like some construction materials. The horizontal movement helps prevent the sieve holes from getting blocked quickly. It also allows for larger samples to be sieved.

Tapping Sieving

This method combines a circular motion with a tapping motion. It's similar to how someone might shake a sieve by hand. The tapping helps denser (heavier) particles pass through the sieves more effectively than just shaking them.

Wet Sieving

Most sieve analyses are done with dry materials. However, sometimes you need to use water. This is common if the material is already mixed with liquid and can't be dried, or if it's a very fine powder that tends to stick together. If fine powders stick together, they can block the sieve holes during dry sieving.

In wet sieving, water is sprayed onto the top sieve while the stack is shaking. The water helps wash the finer particles through the sieves. You keep rinsing until the water coming out the bottom is clear. After rinsing, the material left on each sieve is dried and then weighed. It's important that the water doesn't change the material itself (like making it swell or dissolve).

Air Circular Jet Sieving

This method is perfect for very fine powders that tend to clump together and are hard to separate with regular shaking.

It works using two main parts: a spinning nozzle inside the sieving chamber and a powerful vacuum cleaner. The vacuum cleaner creates a suction inside the chamber. As fresh air rushes in through the spinning nozzle, it speeds up and blows against the sieve mesh. This blast of air spreads out the particles. Above the mesh, the air then flows slowly through the sieve holes, carrying the finer particles into the vacuum cleaner.

Types of Particle Mixes

When we talk about the gradation of a material, we mean the mix of different particle sizes it contains. Here are some common types:

- Dense gradation: This means the sample has a good mix of all different particle sizes. The smaller particles fill in the gaps between the larger ones. This makes the material very solid and strong, with few empty spaces (air voids). On a graph, this looks like a smooth, even curve.

- Narrow gradation: Also called uniform gradation, this means most of the particles in the sample are about the same size. There aren't many small or large particles. On a graph, this curve is very steep and covers only a small range of sizes.

- Gap gradation: In this type, there are very few particles of a medium size. The sample mostly has large and small particles. On a graph, the curve will look flat in the middle size range.

- Open gradation: This means there are very few small particles in the sample. This leaves many empty spaces (air voids) between the larger particles. On a graph, this looks like a flat curve in the small size range.

- Rich gradation: This type of sample has a lot of very small particles.

Types of Sieves

Sieves are made with different kinds of mesh and come in various sizes.

- Woven wire mesh sieves: These sieves are made from wire woven together, like a fabric. They have very precise square openings, ranging from very tiny (20 micrometers) to larger (3.55 millimeters). They come in different diameters, from 100 to 450 millimeters.

- Perforated plate sieves: These sieves are made from a metal plate with holes punched into it. The holes can be round or square. Their openings are usually larger, from 1 millimeter to 125 millimeters. Their diameters range from 200 to 450 millimeters.

- American standard sieves: Also known as ASTM sieves, these follow specific American standards. Their openings can range from 20 micrometers to 200 millimeters. They typically come in two diameters: 8 inches (about 200 mm) and 12 inches (about 300 mm).

Why Particle Size Matters

The way particles are mixed (their gradation) affects many important things about a material. These include how heavy it is for its size (bulk density), how strong and stable it is, and how easily water can pass through it (permeability).

For example, in building roads, engineers want a material that is strong, stable, and doesn't let too much water through. By carefully choosing the right mix of particle sizes, they can achieve these properties.

- A material with an open gradation (lots of big particles, few small ones) will have a lower density and let water pass through easily.

- A material with a rich gradation (lots of small particles) will also have a lower density and might not be very stable, but it will let less water through.

Engineers can adjust the gradation of a material to get the exact properties needed for a specific project.

Real-World Uses

Sieve analysis is used in many engineering projects. The required particle size mix is often specified for each job.

For example, if you're building a foundation for a building, you might only need large, coarse rocks. So, an open gradation material would be chosen.

This test helps engineers understand the properties of soil. This is important because the soil's properties tell them if it can support a building or road. It also helps them decide if the soil needs to be changed and how to make it as strong as possible.

See also

In Spanish: Tamizado para niños

In Spanish: Tamizado para niños

- Soil gradation

- Optical granulometry

Images for kids