Smith Tobacco Barn facts for kids

Quick facts for kids |

|

|

Smith Barn

|

|

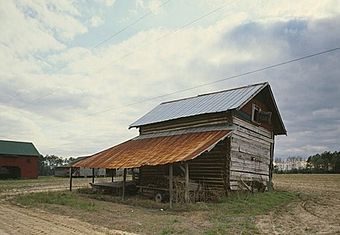

Smith Tobacco Barn in 1987

|

|

| Nearest city | Floydale, South Carolina |

|---|---|

| Built | 1942 |

| Architect | King, J.L. |

| Architectural style | Flue-Cured Tobacco Barn |

| MPS | Flue-Cured Tobacco Production Properties TR |

| NRHP reference No. | 84000568 |

| Added to NRHP | December 4, 1984 |

The Smith Tobacco Barn is an old building in Dillon County, South Carolina. It was used to dry a special type of tobacco called flue-cured tobacco. This barn is located on the east side of a dirt road. It is about 0.4 kilometers south of South Carolina State Highway 17-34. It is also about 0.8 kilometers north of South Carolina State Highway 17-155. The barn is about 1.6 kilometers east of where Highway 17-22 and Highway 155 meet. The Smith Tobacco Barn was added to the National Register of Historic Places on December 4, 1984. This means it is an important historical site.

Contents

History of the Smith Tobacco Barn

How Tobacco Farming Changed in South Carolina

A type of tobacco called Brightleaf tobacco became popular in South Carolina in the late 1800s. This tobacco grew very well in the sandy soil of the Pee Dee region. Farmers used a method called flue-curing to dry it.

How Tobacco Was Dried in the Barns

Old tobacco barns like the Smith Barn had one or two fireboxes. These fireboxes used wood or coal to create heat. In the 1950s, many barns were updated. They started using gas or oil for heat. This helped farmers control the temperature better.

Tobacco leaves were carefully hung on poles inside the barn. The drying process had three main steps:

- Step 1: Yellowing the Leaves

- The temperature was kept low, between 35 and 43 degrees Celsius (95 to 110 degrees Fahrenheit). This step made the leaves turn yellow.

- Step 2: Drying the Leaves

- The temperature was then raised to 54 to 57 degrees Celsius (130 to 135 degrees Fahrenheit). This step dried the main part of the leaves.

- Step 3: Drying the Stems

- Finally, the temperature went up to 71 to 77 degrees Celsius (160 to 170 degrees Fahrenheit). This last step dried the stems of the tobacco leaves.

What the Smith Tobacco Barn Looks Like

The Smith Tobacco Barn is shaped like a rectangle. It has a metal roof that slopes down on two sides, called a gable roof. The bottom part of the barn is made of brick. The walls up to the roof are made of sawn timber. These wooden pieces fit together with notches at the corners. Mortar, a type of cement, fills the gaps between the timbers.

The triangular parts of the walls under the roof, called gable ends, are covered with horizontal wooden boards. There are small, rectangular doors in these gable ends. These doors could be opened to let air in and out.

On the south and east sides of the barn, there are metal shed roofs. These sheds are held up by posts. They provided shade for workers who were stringing the tobacco leaves. The east and west sides of the barn also have small doors at ground level.

Someone scratched the name "J. L. King" and the year "1942" into the mortar. Inside, the barn was divided into five sections or "rooms" by wooden poles. On the south end, there is a brick firebox with two arches. This firebox was later closed up with bricks. Other pictures show that the barn eventually used gas for heating instead of wood or coal.

When the barn was nominated for the National Register of Historic Places, it was no longer used for tobacco. However, it was considered the best-preserved tobacco barn in Dillon and Marion counties. It was built between 1895 and the 1950s. It was also described as a "very fragile resource," meaning it needed protection.