Steam drum facts for kids

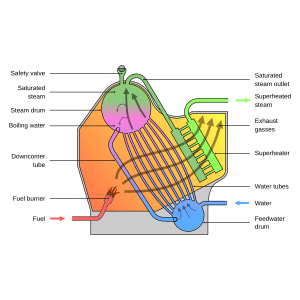

A steam drum is a very important part of a water-tube boiler. Imagine a big, strong tank at the very top of a boiler. This tank is where water and steam meet and get sorted out. It holds the steam made in the boiler's tubes and helps separate the steam from any leftover water. This separation is super important for making sure the steam is clean and ready to do work, like spinning a turbine to make electricity!

Contents

What is a Steam Drum?

A steam drum is like the brain of a water-tube boiler. It's a large, cylindrical container, usually made of strong steel. Its main job is to collect the steam and water mixture that comes from the boiler's tubes. Inside, it has special equipment to make sure that only pure, dry steam leaves the drum. This dry steam then goes on to power things like steam turbines.

How Does a Boiler Work?

To understand a steam drum, let's first quickly look at a boiler. A boiler is a machine that heats water to create steam. In a water-tube boiler, water flows inside many tubes. Hot gases from burning fuel, like coal or natural gas, flow around these tubes. This heat turns the water inside the tubes into steam.

As the water heats up, it turns into a mix of hot water and steam bubbles. This mix then rises up into the steam drum. Think of it like boiling water in a kettle. The steam drum is where all that steam and water from many "kettles" (the tubes) gather.

Why Do We Need a Steam Drum?

The steam drum has several key jobs that make a boiler work safely and efficiently. It's not just a simple tank; it's a vital part of the system.

Separating Steam and Water

One of the most important jobs of the steam drum is to separate steam from water. When water boils in the tubes, it doesn't all turn into steam at once. Some water remains mixed with the steam. If this wet steam goes to a turbine, it can cause damage.

Inside the drum, there are special devices called "steam separators." These devices spin the steam and water mixture. The heavier water droplets are thrown to the sides and fall back down. The lighter, dry steam rises to the top and leaves the drum. This ensures that only high-quality steam is used.

Storing Water and Steam

The steam drum also acts as a storage tank. It holds a reserve of water for the boiler. This is important because the boiler needs a continuous supply of water to make steam. If the water level drops too low, the boiler could overheat and be damaged.

It also stores a small amount of steam. This helps to keep the steam pressure steady, even if the demand for steam changes slightly.

Helping Water Move Around

The steam drum is part of a natural circulation system. Hot water and steam rise from the boiler tubes into the drum. The cooler, denser water then flows down from the drum through other tubes. This creates a continuous loop, or "circulation," of water. This circulation helps to keep the boiler tubes cool and prevents them from overheating.

Where Are Steam Drums Used?

Steam drums are found in many places where large amounts of steam are needed. The most common place is in power stations. These stations use steam to spin large turbines, which then generate electricity for homes and businesses.

They are also used in some large industrial plants. These plants might need steam for heating processes or to power machinery. Big ships, especially older ones, might also use boilers with steam drums to power their engines.

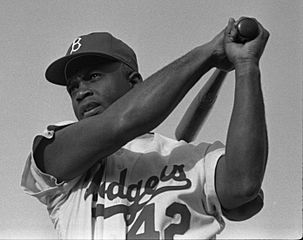

| Jackie Robinson |

| Jack Johnson |

| Althea Gibson |

| Arthur Ashe |

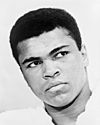

| Muhammad Ali |