Stereolithography facts for kids

Stereolithography (often called SLA or resin printing) is a type of 3D printing technology. It creates 3D objects by building them up layer by layer. It uses a special liquid plastic (called resin) that hardens when light shines on it. This process helps make models, test parts (prototypes), and even final products.

Scientists started researching this idea in the 1970s. The name "stereolithography" was first used by Chuck Hull in 1984. He got a patent for the process in 1986. SLA can be used to make new product designs, medical models, and parts for computers. It's fast and can create almost any shape, but it can also be expensive.

Contents

History of SLA Printing

Stereolithography, or SLA printing, is one of the oldest and most widely used 3D printing methods. In the early 1980s, a Japanese researcher named Hideo Kodama first developed the idea of building objects in layers. He used ultraviolet light to harden special plastics.

In 1984, just before Chuck Hull filed his own patent, some French inventors also filed a patent for a similar process. However, their patent application was later dropped.

The word "stereolithography" comes from Greek words meaning "solid" and "writing." Chuck Hull used this term in 1984 when he applied for his patent. Hull's patent described how to make 3D objects by "printing" thin layers. He used a special liquid plastic that hardens when hit by ultraviolet light. The light beam focuses on the liquid, creating each layer of the object. This process connects the plastic molecules together, making a solid shape.

Hull invented this method to help engineers create test models of their designs much faster. After his patent was approved in 1986, Hull helped start the world's first 3D printing company, 3D Systems. This company helped bring SLA technology to the public.

SLA printing became very popular in industries like car manufacturing. This helped 3D printing become an important technology. Today, it continues to be used in many different areas.

How SLA Technology Works

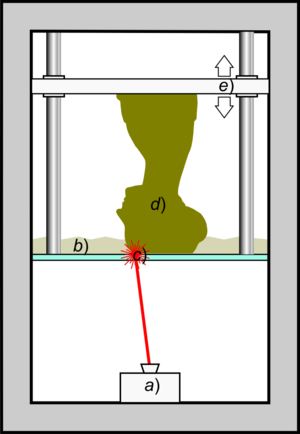

Stereolithography is a process where objects are built by adding material layer by layer. In its most common form, a special ultraviolet (UV) laser shines onto a tank of liquid plastic, called photopolymer resin.

Using computer software (like CAD/CAM), the UV laser draws a specific design or shape onto the surface of the liquid. Since these photopolymers are sensitive to UV light, the resin hardens and forms one solid layer of the 3D object.

After one layer is finished, the building platform moves down a little. A blade then spreads a new thin layer of liquid resin over the hardened part. This process repeats for every layer of the design until the 3D object is complete. Once printed, the finished parts need to be washed with a special liquid to clean off any wet resin.

It's also possible to print objects "bottom-up." This uses a tank with a clear bottom. The laser shines upward through the bottom of the tank. In this method, the platform starts low and moves up as each layer is printed. This way, you only need enough liquid resin to keep the bottom of the tank full. This "bottom-up" method is often used in smaller, desktop SLA printers. Larger industrial systems usually use the "top-down" approach.

SLA printing often needs support structures. These are like temporary pillars that hold up parts of the object as it prints. They prevent parts from bending or falling. Supports are usually added automatically by the computer program. After printing, these supports must be carefully removed by hand.

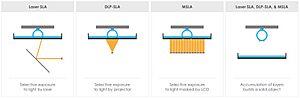

Other types of stereolithography use LCD screens or DLP projectors instead of lasers to harden the resin.

Materials Used in SLA

The liquid materials used for SLA printing are called "resins." These are special types of plastics that harden when exposed to light. Many different types of resins are available to buy. People can also make their own resins to test new ideas.

The properties of these resins can change depending on how they are made. Some resins can be soft, while others are very hard. Some can be mixed with other materials like glass or ceramic. Others are designed to handle high heat or resist impacts.

Recently, scientists have been looking into using more eco-friendly or reusable materials to create "sustainable" resins.

Here are some common types of resins:

- Standard resins: Used for general test models.

- Engineering resins: Have specific strengths and heat resistance.

- Dental and medical resins: Safe to use for things that go in or on the body.

- Castable resins: Used to make molds that burn away completely, leaving no ash.

- Biomaterial resins: Made from water-based solutions of natural or man-made polymers, like gelatin or hyaluronic acid. These are often used in biological research.

Uses of Stereolithography

Medical Modeling

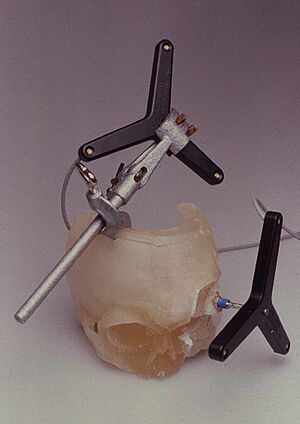

SLA models have been used in medicine since the 1990s. They help create accurate 3D models of a patient's body parts. These models are based on data from medical scans like CT scans or MRIs.

First, doctors get a scan of the patient. This scan shows different body tissues as different shades of gray. By choosing certain gray values, specific tissues or organs can be separated. This process is called segmentation. The segmented data is then turned into a format that the SLA printer can use.

While SLA printing is usually very accurate, the quality of a medical model depends on many things. The most important is that the person doing the segmentation does it correctly. There can be small errors, but skilled operators can avoid them.

Medical models made with SLA are used to help doctors with many tasks:

- Diagnosis: Understanding a patient's condition better.

- Planning Surgeries: Surgeons can practice complex operations, like bone cuts, on the model before operating on the patient.

- Designing Implants: Models help design custom-fit implants, like plates for skull repairs (cranioplasty).

In 2019, scientists at Rice University showed how soft, gel-like materials could be used with SLA for biological research.

Prototyping

Stereolithography is often used to create test parts, known as prototypes. For a fairly low cost, SLA can make very accurate prototypes, even for parts with unusual shapes. Businesses use these prototypes to check their product designs. They can also use them to show off what the final product will look like.

Advantages and Disadvantages

Advantages

One great thing about stereolithography is its speed. Functional parts can be made within a day. The time it takes depends on how complex and big the design is. Printing can take anywhere from a few hours to more than a day.

Unlike some other 3D printing methods, SLA parts usually look very smooth. You can't easily see the layers. The surface quality is generally much better. SLA printed parts are also strong enough to be shaped further with tools. They can even be used to make master models for other manufacturing processes, like injection molding or metal casting.

Disadvantages

Even though stereolithography can make almost any design, it can be expensive. However, the cost has been coming down. Since 2012, more affordable SLA machines have been designed for home users. Starting in 2016, new methods using high-resolution LCD screens have made prices even lower, sometimes under $200. These methods can achieve very fine details, down to 0.01 mm.

Another downside is that the liquid plastics (photopolymers) are sticky and messy. They need to be handled carefully. Newly printed parts also need to be washed, dried, and hardened further. The environmental impact of these processes is still being studied. Generally, SLA resins are not biodegradable, unlike some other 3D printing materials like PLA.

Finally, the choice of materials for SLA is limited compared to other 3D printing methods. For example, Fused filament fabrication (FFF) can use almost any type of thermoplastic.

See also

- Fused filament fabrication (FFF or FDM)

- Selective laser sintering (SLS)

- Thermoforming

- laminated object manufacturing (LOM)

Images for kids