Sulfur dye facts for kids

Sulfur dyes are a very popular type of dye used to color fabrics, especially cotton. They are known for being affordable, easy to use, and for making colors that last a long time without fading when washed. You'll often find sulfur dyes in colors like black, brown, and dark blue. While true red sulfur dyes are not common, some lighter pink or scarlet shades can be made.

Contents

What Makes Sulfur Dyes Special?

Sulfur dyes get their name because they contain sulfur as a key part of their chemical structure. This sulfur helps create the vibrant colors we see. These dyes are unique because they don't dissolve in water on their own. This special feature is actually what helps them stick so well to fabrics!

How Sulfur Dyes Work: The Dyeing Process

Dyeing fabric with sulfur dyes involves several steps. Imagine you want to color a white T-shirt. Here's how it generally works:

Making the Dye Ready: Reduction

Since sulfur dyes don't dissolve in water, they need a little help to get into the fabric fibers. This help comes from a chemical process called reduction. A special chemical, often sodium sulfide, is added to the dye in hot water. This makes the dye particles break down and become soluble, meaning they can now dissolve in the water. Once dissolved, the dye can easily soak into the cotton fabric.

Attaching to Fabric and Fixing the Color

After the fabric has soaked up the dissolved dye, it's time to make the color permanent. This is done through a process called oxidation. When the fabric is exposed to air, or sometimes to another chemical like hydrogen peroxide, the dye changes back to its original, water-insoluble form. This traps the color inside the fabric fibers.

Finally, the fabric is washed and soaped to remove any extra dye that didn't stick. This whole process ensures the color is locked in. The fact that the dye becomes insoluble again is why sulfur-dyed clothes have good wash-fastness – the color won't easily run or stain other clothes when washed.

Sometimes, a gas called hydrogen sulfide can form during dyeing. This gas can be tricky for metal equipment, so special stainless steel tanks are often used to keep everything safe. Also, if there's too much sulfur left on the fabric, it can sometimes weaken the material over time. To prevent this, another chemical, sodium acetate, is used as a final treatment.

A Look Back: The History of Sulfur Dyes

The story of sulfur dyes began a long time ago. One of the earliest examples, called "Cachou de Laval," was discovered in 1873. It was made by treating natural materials like sawdust or straw with sulfur-containing chemicals. Later, in 1893, a scientist named Henri-Raymond Vidal created "Vidal Blacks" by mixing other chemicals with sulfur. These early discoveries showed that combining certain compounds with sulfur could create strong, deep colors.

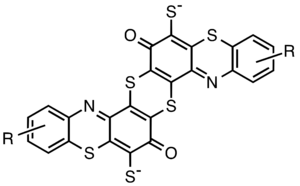

One of the most important sulfur dyes is called Sulfur Black 1. It's made by mixing two chemicals, 2,4-dinitrophenol and sodium sulfide, in hot water. The exact chemical steps are quite complex, but the result is a very strong black dye. Scientists believe this dye is made up of many small parts linked together by sulfur. Other sulfur dyes, like Sulfur Orange 1 and Sulfur Brown 21, are made using similar methods.

Why Sulfur Dyes Are Used (and Their Challenges)

Sulfur dyes are widely used for several good reasons, but they also have some challenges.

Benefits of Sulfur Dyes

- Affordable: They are generally inexpensive to produce, making them a cost-effective choice for coloring large amounts of fabric.

- Good Wash-Fastness: Once the dye is fixed in the fabric, it doesn't easily wash out. This means your clothes keep their color well, even after many washes.

- Easy to Apply: The dyeing process is relatively straightforward, which makes them popular in textile factories.

- No Stains: Because the dye becomes insoluble in water after oxidation, it won't bleed onto other clothes in the washing machine.

Things to Watch Out For

- Rubbing Fastness: Sometimes, the color from sulfur dyes might rub off a little if the fabric is rubbed hard.

- Chlorine Bleach: These dyes can be bleached by chlorine, so it's best to avoid chlorine bleaches when washing sulfur-dyed items.

Caring for Our Planet: Environmental Considerations

In the past, the process of making and using sulfur dyes sometimes created wastewater that wasn't good for the environment. However, companies and scientists have been working hard to make these dyes more eco-friendly.

Today, safer chemicals, like glucose (a type of sugar), are being used as reducing agents instead of older, more harmful ones. This has led to the development of "low-sulfide" and even "zero-sulfide" dyes, which are much better for our planet! New methods, like using electricity to help with dyeing, are also being explored to make the process even cleaner and more sustainable. These advances show a commitment to protecting our environment while still enjoying colorful fabrics.