The Morning Star Company facts for kids

|

|

| Private | |

| Industry | Food products |

| Founded | 1970 |

| Founder | Chris J. Rufer |

| Headquarters | Woodland, California |

|

Key people

|

Chris J. Rufer |

The Morning Star Company is a big food company based in Woodland, California. It started in 1970. The company was first created by Chris Rufer. He began by using trucks to move tomatoes. Chris Rufer still owns the company today.

Morning Star processes a lot of tomatoes. They handle about 40% of all the tomatoes grown for processing in California. They provide a large amount of tomato paste and diced tomatoes for the U.S. market. Each year, they process around 5 million tons of tomatoes. Their factories can handle over 3,000 tons of tomatoes every hour.

The company has about 550 full-time workers. During the tomato harvest season, they hire over 2,500 extra workers. Morning Star earns more than $1 billion each year. As of late 2023, it is the world's top company for processing tomatoes. It supplies about 10% of all the tomato products used as ingredients worldwide.

Morning Star is a "vertically integrated" company. This means they handle many steps of their business themselves. Their related companies grow and plant tomato seedlings. They also harvest the tomatoes and deliver them to the factories.

The company is known for its special way of working. They have "no supervisory management." This means there are no bosses telling people what to do. The owner, Chris Rufer, calls this "Mission Focused Self-Management." Workers are encouraged to come up with new ideas on their own. They also decide what their job responsibilities are. They can even make choices about buying new equipment after talking with experts. Workers' pay is decided by their co-workers' evaluations.

In 2013, INC Magazine called Morning Star one of its "Audacious Companies." This means they were recognized for being bold and innovative.

Company History

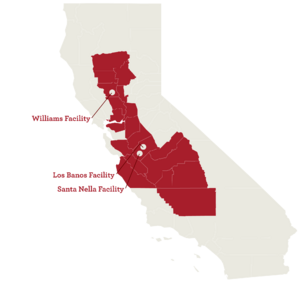

Chris Rufer started Morning Star in 1970. He began by driving trucks himself. He moved tomatoes from farms to places where they were canned. Morning Star opened its first factory in Los Banos, California in 1990.

Later, they built more factories. A second factory was built in Williams, California in 1995. A third factory opened in Santa Nella, California in 2002.

How Tomatoes Are Processed

Morning Star uses new ideas to make tomato paste. They have made many changes to improve their factories. For example, they use systems that rely on gravity to unload tomatoes. This helps save energy.

They also use cooling ponds and elevated unloading systems. These methods help save energy too. The company also uses a special 300-gallon bag-in-box packaging system. All these changes help the company make tomato paste in a way that is good for the environment and very efficient.

Images for kids

See also

- Worker Cooperative

- Dominos Pizza - The Morning Star Company supplies most of the tomato pizza sauce for the USA market.

- Heinz Tomato Ketchup - The Morning Star Company supplies most of the tomato paste ingredients for the USA market.

- Zappos

- Holacracy