Tyrconnel Mine and Battery facts for kids

Quick facts for kids Tyrconnel Mine and Battery |

|

|---|---|

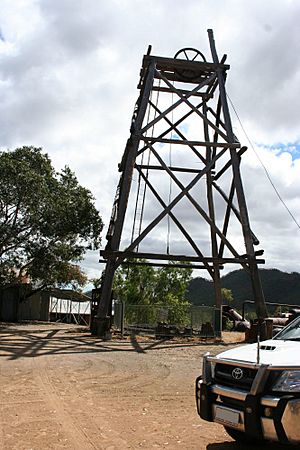

Tyrconnel Mine and Battery, 2010

|

|

| Location | between Kingsborough and Thornborough, Shire of Mareeba, Queensland, Australia |

| Design period | 1870s - 1890s (late 19th century) |

| Built | 1876 - 1980s |

| Official name: Tyrconnel Mine and Battery | |

| Type | state heritage (built, archaeological) |

| Designated | 21 October 1992 |

| Reference no. | 600687 |

| Significant period | 1876-1980s (fabric) 1876-1899, 1912-1924, 1930s-1940s, 1960s, 1980s (historical) |

| Significant components | machinery/plant/equipment - mining/mineral processing, tailings dump, residential accommodation - manager's house/quarters, dam/reservoir, shaft, battery shed, cyanide plant/cyanide vat, battery/crusher/stamper/jaw breaker |

| Lua error in Module:Location_map at line 420: attempt to index field 'wikibase' (a nil value). | |

The Tyrconnel Mine and Battery is an important old gold mine in Queensland, Australia. It is located between the towns of Kingsborough and Thornborough. The mine was active from 1876 until the 1980s. Today, it is protected as a heritage site. It was added to the Queensland Heritage Register in 1992.

Contents

History of Gold Mining at Tyrconnel

Discovering Gold in 1876

The Tyrconnel Mine was one of the richest gold mines in the Hodgkinson Goldfield. Gold was first found here in 1876 by Redmond and McVeigh. The mine was named after "Tír Chonaill," an old Irish name for a region in Ireland. This area is now mostly County Donegal.

Early Gold Processing

The first machine to crush gold ore at the mine was set up in November 1876. It was called Warde and Company's battery. A battery is a machine with heavy stamps that crush rock to get the gold out. This battery started working in February 1877. Its owners later renamed it the Brisbane battery.

Challenges and New Beginnings

By 1888, the Tyrconnel mine shaft was 128 meters deep. However, the mine closed because it was full of water. Even so, it had already produced 18,000 ounces of gold from 11,000 tons of rock. The mine was put up for sale in 1897. A group from Sydney bought it.

In 1899, the mine was still having problems with water. The owner, William Keating Snr, dug a new shaft. He found good samples of gold-rich rock. He tried to sell the mine to a group in Melbourne.

Reopening and Upgrades in the 1910s

A new company took over the mine in 1912. They appointed David Morgan as the new manager. By 1913, they had set up new equipment. They bought a ten-head battery from another mine and moved it to Tyrconnel. Moving the heavy machinery cost £80.

The mine's first gold crushings were very good. They got 1,041 ounces of gold from 945 tons of rock. They also installed new machines like a compressor and rock drills. In October 1913, they found a wide vein of gold-rich quartz. The battery started crushing gold in February 1914.

More Power and Gold Extraction

In 1915, the battery's engine broke down. An electrical system was installed to provide light and pump water. In 1916, the mine's boiler was fixed. They also started using cyaniding to get more gold from the leftover crushed rock. Cyaniding uses chemicals to dissolve the gold.

In 1917, Tyrconnel Gold Mines Limited bought another battery and moved it to the site. This made the Tyrconnel battery even bigger. The crushed ore went straight into the cyanide plant. By 1918, they had a 20-head stamper, which meant it had 20 heavy stamps for crushing rock. They also added a large boiler.

Later Operations and Modernization

More new equipment arrived in 1919, including a new head gear and a powerful air compressor. A dynamo was installed in 1922 to provide light. Operations stopped in 1924.

In the 1930s, people started treating the old crushed rock (sands) with cyanide again. In 1935, new machinery was ordered from overseas. The battery was updated to process 60 tons of ore per day. A new company, Queensland Gold Development Syndicate, reconditioned the mine. They built a new headframe and a 10-head battery. They also built a concrete dam for water.

Another new battery was built in 1936. This one included a jaw crusher, a ball mill, and a 10-head stamper. This company stopped working in 1937 due to a lack of money.

The battery was repaired in 1940. A new jaw crusher and a Wilfley table were installed. A Wilfley table helps separate gold from other minerals. By the end of World War II, all mines in the area had closed.

Recent Activity and Tourism

The mine became active again in the late 1960s and early 1980s. In 1984, a fire damaged some of the mine's timber structures. The mine's waste piles were treated with cyanide again in the 1980s.

Today, the Tyrconnel Mine is a tourist attraction called the Tyrconnel Outback Experience. Visitors can take guided tours of the mine site. There is also accommodation available, including the old mine manager's house.

What You Can See Today

The Tyrconnel Mine site has four main parts: the living quarters, the mine itself, the battery, and the cyanide works.

Living Quarters

The living quarters are located above the battery and cyanide works. They include a cottage and kitchen made of corrugated iron. There are also other small buildings, including a workshop.

The Mine Area

The mine shaft now has a concrete collar and is covered with a grid for safety. You can still see the concrete bases of the old timber headframe. The headframe and winding shed were destroyed by fire. The winding plant has parts of a winding engine, steam engines, and boilers.

The Battery Shed

The battery shed is a large building made with strong timber posts. It has a corrugated iron roof and walls. Inside, there are two sets of timber bins that held the gold ore. The main crusher is gone, but timber chutes lead to two mortar boxes. These boxes held the rock for the two five-head stamp batteries. Two Petter crude oil engines powered the battery. One of these engines still works. Most of the other gold-separating machines have been removed, except for a Wilfley table.

Cyanide Works and Dam

Below the battery shed, you can see the remains of a tailings dump. This is where the waste rock was piled after crushing. There are also seven cyanide tanks. The last time cyanide treatment happened here was in 1986. A small cottage near the cyanide plant was once the battery manager's house. The battery dam on Tyrconnel Creek is still there.

Surviving Equipment

Many pieces of old mining equipment are still at the site. These include:

- A Colonial boiler made by Walkers Limited.

- Two Cornish boilers (no brand visible).

- A large steam air compressor made by Thompson Engineers.

- A steam winding engine made by Tooth & Co.

- Two five-head stamp batteries made by Fraser Chalmers.

- Two mortar boxes (not in their original place).

- Two two-cylinder crude oil engines made by Petter.

- A small kerosene engine.

- A Wilfley table.

- A Berdan pan (not in its original place).

- A grinding pan made by Kalgoorlie Foundry Engineers.

- An egg-end air receiver.

- A small retort furnace.

Why Tyrconnel Mine is a Heritage Site

The Tyrconnel Mine and Battery was added to the Queensland Heritage Register in 1992. This means it is a very important historical place.

Showing Queensland's History

This site is important because it shows how gold mining developed in Queensland from 1876 to the 1980s. It has many different types of machinery from different time periods.

Rare and Special Features

It is rare to find a mining site where the living quarters, mine, battery, and cyanide works are all still close together and mostly intact. The battery shed is one of only a few in North Queensland that still has its original machinery. The Thompson air compressor and the Vulcan winding engine are also very rare. The cyanide plant is also well-preserved because it was used recently.

Showing How Gold Mining Worked

The buildings and machinery at Tyrconnel are still quite complete. This allows visitors to see the entire gold mining process. You can trace the steps from digging up the ore to crushing it and finally extracting the gold.

| Sharif Bey |

| Hale Woodruff |

| Richmond Barthé |

| Purvis Young |