Gold cyanidation facts for kids

Gold cyanidation is a special way to get gold out of ore (rock that contains metal). It's also called the cyanide process. This method uses a chemical called cyanide to turn gold into a liquid form that can be easily collected. It's the most common way to get gold from rocks, especially from low-grade ores (rocks with only a little gold). This process is also used to get silver.

Making the chemicals needed for gold mining uses over 70% of the world's cyanide. While other metals like copper and zinc can also be recovered, gold is the main reason this method is used. Because cyanide is very poisonous, this process is debated, and some places have even banned it. However, cyanide can be used safely in mining if the water's pH level is kept high (above 10.5), which means it's very alkaline. Miners often use lime to control this pH.

Contents

How it Started

In 1783, a scientist named Carl Wilhelm Scheele found that gold could dissolve in water mixed with cyanide. Later, other scientists like Bagration (1844), Elsner (1846), and Michael Faraday (1847) figured out that each tiny piece of gold needed two cyanide parts to dissolve.

Making it Industrial

Gold mining in South Africa's Witwatersrand area started to slow down in the 1880s. This was because the new gold found there was often mixed with pyrite (a mineral also known as "fool's gold"). The gold couldn't be easily taken out of this type of rock with the methods available back then.

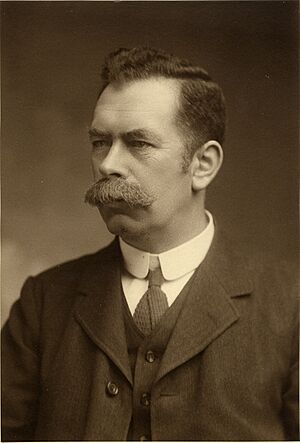

In 1887, John Stewart MacArthur, along with brothers Robert and William Forrest, developed the MacArthur–Forrest process. They worked for the Tennant Company in Glasgow, Scotland. They found that by crushing the gold ore and mixing it in a cyanide solution, they could get out up to 96% of the pure gold. This new method was first used in South Africa's Witwatersrand in 1890. Even with some early problems, it led to a big increase in gold mining.

By 1891, a pharmacist named Gilbert S. Peyton improved the process at his mine in Utah, USA. This was the first time the cyanide process was successfully used for business in the United States. Around 1900, American metallurgist Charles Washington Merrill and engineer Thomas Bennett Crowe made the process even better. They used a vacuum and zinc dust to recover the gold from the cyanide liquid. This improved method is now called the Merrill–Crowe process.

The Chemistry Behind It

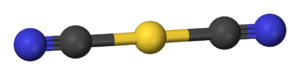

The main chemical reaction that dissolves gold is known as the "Elsner equation":

- 4 Au + 8 NaCN + O2 + 2 H2O → 4 Na[Au(CN)2] + 4 NaOH

This equation shows that gold (Au) reacts with sodium cyanide (NaCN), oxygen (O2), and water (H2O). This reaction creates a special gold compound that dissolves in water, called dicyanoaurate. It also creates sodium hydroxide (NaOH). Sometimes, other types of cyanide like potassium cyanide or calcium cyanide are used instead of sodium cyanide.

Gold is one of the few metals that can dissolve when cyanide ions and oxygen are present. Once the gold is dissolved into this dicyanoaurate compound, it can be collected by sticking to activated carbon.

How it's Used

First, the gold ore is crushed into very small pieces using grinding machines. Sometimes, it's further cleaned using methods like froth flotation or gravity separation. Then, water is added to the crushed ore to make a thick mixture, like a muddy soup, called a slurry. This slurry is then mixed with a solution of sodium cyanide or potassium cyanide. Many mines use calcium cyanide because it costs less.

To stop a dangerous gas called hydrogen cyanide from forming, miners add lime (calcium hydroxide) or soda (sodium hydroxide) to the mixture. This keeps the liquid very basic, with a pH above 10.5. Adding lead nitrate can also help the gold dissolve faster and get more gold out, especially from ores that are partly oxidized.

The Role of Oxygen

Oxygen is very important for the cyanide process to work. It helps take electrons from the gold. If there isn't enough oxygen dissolved in the mixture, the gold will dissolve much slower. To fix this, air or pure oxygen gas can be bubbled through the slurry. Special equipment is used to make sure the oxygen mixes well with the liquid. This helps increase the amount of dissolved oxygen. Oxygen can also be added by putting hydrogen peroxide solution into the slurry.

Preparing the Ore

For some types of ore, especially those that contain sulfur, it helps to mix the ore with water and keep the pH high *before* adding cyanide. This step is called "pre-aeration." It makes elements like iron and sulfur less likely to react with the cyanide. This way, the gold cyanidation process works better. For example, it helps prevent cyanide from being wasted by reacting with iron or sulfur compounds.

Getting Gold from Cyanide Solutions

Once the gold has dissolved in the cyanide solution, there are several ways to get it back. The most common and cost-effective methods are:

- Carbon in pulp: The gold sticks to tiny pieces of activated carbon.

- Electrowinning: Electricity is used to pull the gold out of the solution.

- Merrill–Crowe process: Zinc dust is used to make the gold fall out of the solution.

Cleaning Up Cyanide Waste

The cyanide left over in the waste water from gold mines can be dangerous. So, many mines have a special step to clean up these waste streams. This step lowers the amount of cyanide compounds. Processes like the INCO process and the Caro's acid process change cyanide into a less toxic substance called cyanate. Cyanate can then react to form harmless substances like carbonates and ammonia.

- CN− + [O] → OCN−

- OCN− + 2 H2O → HCO−

3 + NH3

These cleanup processes can reduce cyanide levels significantly, making the water safer for the environment. For example, the Caro's acid process can lower cyanide levels to very low amounts, which is usually safe enough to release into special storage areas called tailings ponds. Other chemicals like hydrogen peroxide can also be used to clean up cyanide.

Impact on the Environment

Even though cyanide is used in 90% of gold production, it's a very debated topic because it's so toxic. While cyanide solutions in water break down quickly in sunlight, other less toxic chemicals that form, like cyanates, can stay in the environment for years.

Big cyanide spills have not killed many people directly, as people can be warned to stay away from polluted water. However, these spills can cause huge damage to rivers, sometimes killing all living things for many miles downstream. Luckily, cyanide usually washes out of rivers quickly. If animals and plants can move in from clean areas upstream, the affected areas can recover. For example, after a spill in Romania, tiny organisms in the river returned to 60% of their normal levels within 16 days.

Here are some famous cyanide spills:

| Year | Mine | Country | What Happened |

|---|---|---|---|

| 1985–1991 | Summitville | US | Cyanide leaked from a storage area. |

| 1980s–present | Ok Tedi | Papua New Guinea | Waste was released without proper control. |

| 1995 | Omai | Guyana | A dam holding waste broke. |

| 1998 | Kumtor | Kyrgyzstan | A truck carrying cyanide fell off a bridge. |

| 2000 | Baia Mare | Romania | A dam holding waste broke (see 2000 Baia Mare cyanide spill). |

| 2000 | Tolukuma | Papua New Guinea | A helicopter dropped a crate into the rainforest. |

| 2018 | San Dimas | Mexico | A truck leaked cyanide into a river. |

These spills have led to strong protests against new mines that plan to use cyanide. Examples include projects in Romania, Australia, Chile, and Malaysia.

Other Ways to Get Gold

Cyanide is cheap and works well, and it can break down naturally. However, because it's so toxic, scientists are looking for other ways to extract gold. Some alternatives that have been studied include thiosulfate, thiourea, iodine, ammonia, liquid mercury, and glycine-based liquids. The main challenges with these alternatives are their cost and how well they can recover gold. Thiourea has been used in some mines.

Rules and Laws

Some places have banned cyanide mining, like the US states of Montana and Wisconsin, the Czech Republic, and Hungary. The European Commission decided not to ban it across the whole EU, saying that existing rules already protect the environment and health. Several attempts to ban gold cyanidation in Romania have also failed. However, there are still protests in Romania asking for a ban on cyanide in mining.

In the EU, the use of dangerous chemicals is controlled by special rules. For example, "free cyanide and any compound that can release free cyanide in solution" are strictly controlled. This means that no amount of cyanide that could harm groundwater can be released.

After the big 2000 Baia Mare cyanide spill, the European Parliament made new rules for managing waste from mining. These rules say that mines must reduce cyanide in their waste to the lowest possible level using the best available methods. New mines started after May 1, 2008, cannot release waste with more than 10 parts per million (ppm) of a certain type of cyanide. Older mines had higher limits at first, but they have to lower them over time.

Also, under these rules, mining companies must have financial guarantees. This means they need to show they have enough money to clean up the mine site after they finish mining. This rule can make it harder for smaller companies to start gold mines in the EU.

The mining industry has also created a voluntary "Cyanide Code." This code helps mines reduce their environmental impact by having outside experts check how they manage cyanide.