- This page was last modified on 17 October 2025, at 10:18. Suggest an edit.

W & J Galloway & Sons facts for kids

|

|

| Industry | Engineering |

|---|---|

| Fate | Defunct |

| Predecessor | William & John Galloway |

| Successor | Hick, Hargreaves & Co. Ltd. |

| Founded | 1790 |

| Founder | William Galloway |

| Defunct | 1933 |

| Headquarters |

,

England

|

|

Key people

|

John Galloway (Inventor) |

| Products | Steam engines Boilers for steam engines |

W & J Galloway & Sons was a British company that made steam engines and boilers. They were based in Manchester, England. The company started in 1835 when two brothers, William and John Galloway, teamed up. Later, their sons joined the business. In 1889, it became a bigger company. They stopped trading in 1932.

The Galloway brothers learned their skills from their father, who built waterwheels and gears for mills. When they started their own company, it grew to be a top maker of steam engines and industrial boilers. They were known for being clever and creative. Their products were used all over the world for many different things, like making electricity and refrigeration. The company grew as steam power became more popular in factories. But when electricity took over, the company eventually closed down.

Contents

History: How a Family Business Grew

Early Days: Galloway, Bowman and Glasgow

William Galloway was born in Scotland in 1768. He became a millwright, someone who builds and repairs mills and machinery. In 1790, he moved to Manchester, a busy industrial city in England. Many other Scots moved there too, hoping to find work in the fast-growing industries.

In 1806, William started a business with his friend, James Bowman. William asked James to invest £200, which was a lot of money back then! They set up shop at the Caledonia Foundry. At first, they were just millwrights. But by 1813, they added "engineers" to their description, and by 1817, they were also "ironfounders," meaning they made things from iron. Being an "engineer" for machines was a new and exciting job at that time.

Around 1820, William Glasgow, a skilled iron worker, joined the team. He helped manage the new iron-making part of the business. The company made water wheels, gears, and other machines for all kinds of mills. They even worked for customers in France and the United States!

John Galloway, William's son, later wrote that most of the original millwrights in Manchester came from the Scottish Borders, just like his father. He said they were "quiet, respectable and mostly middle aged, with experience." He also noted that workers back then had to understand almost the whole process of making something, not just one small part.

The company, Galloway, Bowman and Glasgow, became the repair shop for the new Liverpool and Manchester Railway. In 1830–31, they built their first steam locomotive, called the Manchester. The next year, they made the Caledonian. These early trains had wooden wheels with metal tires.

At first, these locomotives had some problems, but the company fixed them. For example, the Caledonian sometimes went off the tracks and had to be rebuilt. The company built about four or five locomotives. John Galloway junior later said that they didn't think the train business would be very big. He thought only about 20 engines would ever be needed!

However, building these locomotives taught them a lot. They learned how to make boilers that could handle much higher pressure (50 psi) than normal factory engines (5 or 10 psi). This experience helped them become very good at making stationary steam engines later on. Getting the huge locomotives out of the factory and onto the railway was also a big challenge!

The company made many different things, like parts for coal mines and the railway, machines for silk mills, and steam engines for cotton mills. They even made pipes for a brewery and a machine for rolling lead.

William Galloway senior died in 1836, and James Bowman died in 1838. The Galloway brothers then decided to start their own business.

W & J Galloway: Brothers in Business

In 1835, William and John Galloway started their own company, called W. and J. Galloway. They had been thinking about it for a while, as John felt there were "too many in partnership already."

The brothers built a new factory at Knott Mill in Hulme, near the River Medlock. Being close to the river was important because they needed water for making iron and running their steam engines. The river was quite polluted from other factories, which sometimes caused problems with their boilers.

Before 1840, they had already built at least two steam engines for other companies. In 1840, they started making gas pipes and equipment for gasworks, which was a new and growing industry. From 1842 to 1847, the brothers also partnered with Joseph Haley to make special lifting jacks and machines for cutting and punching metal. They had six of these machines in their factory, and each could make two tons of rivets a day!

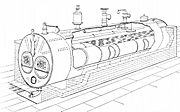

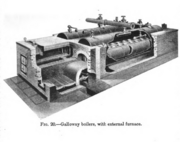

From 1848 onwards, the brothers got many patents related to steam power. John Galloway was especially interested in making boilers more efficient. Their most important invention was the Galloway boiler, patented in 1851. They had already built some of these boilers before getting the patent, and one was even shown at the Great Exhibition in 1851. The company built about 9,000 of these boilers by 1891 and also allowed other companies to make them. This part of the business grew so much that in 1872, they opened another factory in Ardwick just for boilers, leaving the Knott Mill works to focus on engines.

The Galloway boiler was an improvement on an earlier design called the Lancashire boiler. The Galloways worked with a consulting engineer named Robert Armstrong to make their boiler even better.

Working with Henry Bessemer and Steel

Starting in 1855, the company worked with Henry Bessemer, who invented a famous way to make steel called the Bessemer process. Bessemer called William Galloway "my old friend." They had been customers since 1843.

Bessemer and Galloways did many experiments together at the Knott Mill Ironworks in 1855. This was when Bessemer was trying to prove his new steel-making method. It's believed that the first pieces of Bessemer steel were made at the Knott Mill Ironworks. The Galloways were also the first company to get a license to use Bessemer's process in Manchester, even before he told the public about it.

However, the first tests didn't work as planned. It turned out that the iron they were using had a chemical called phosphorus, which caused problems. Bessemer had to give money back to the companies that had bought licenses. It took him two more years to fix the problem.

When Bessemer finally solved the technical issues in 1858, the Galloways gave up their license. Instead, they became partners with Bessemer and others to build and run his steel works in Sheffield. This new company, Henry Bessemer & Co., started in 1859. It made steel much cheaper than before. The Galloways supplied equipment for this factory and for other companies that used Bessemer's process. The business became very successful.

The Galloways also supplied hydraulic equipment for Bessemer's experimental ship, the SS Bessemer. This ship was supposed to have a special room that wouldn't rock with the waves, but the ship had steering problems and the project was stopped.

W & J Galloway & Sons: The Next Generation

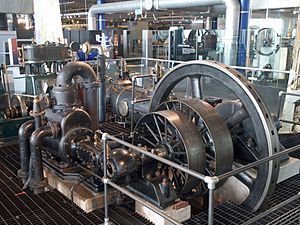

Galloway uniflow steam engine, now in Thinktank, Birmingham Science Museum

In 1856, the sons of the company's founders joined the business. John Galloway (William's son) and Charles John Galloway (John's son) became partners. The company's name changed to reflect this, becoming W & J Galloway & Sons.

During the 1850s and 1860s, the company sold many products overseas to countries like Turkey, India, and Russia. They made everything from gunpowder mills to steam engines for various uses. They also built cast iron columns for buildings, constructed the Southport Pier, and built a long railway bridge over the River Leven in Cumbria. For the pier and bridge, John Galloway invented a new way to build them using powerful water jets to make holes for the support piles.

Around 1873, the company supplied two large engines to the famous Krupp steelworks in Germany. In this decade, Galloways started using flat belt drive systems to transfer power from their steam engines to factory machines. This was common in the US but new in Britain. It was better because it made less noise, wasted less energy, and was easier to fix. Later, rope drive systems became even more popular.

Charles John Galloway was very interested in exhibitions. The company showed off their boilers and engines at big events like the 1873 Vienna Universal Exhibition and the 1876 Philadelphia International Exhibition. Charles John even received special awards from France after the Paris Exhibitions of 1878 and 1889. He was also very active in organizing the Royal Manchester Jubilee Exhibition in 1887.

Galloways Ltd.: A Public Company

In 1889, the company became a private limited company called Galloways Ltd. This meant it had shareholders. Charles John Galloway became the chairman and managing director. John Galloway junior, who had many other business interests and was a local judge, died in 1894. His son, William Johnson Galloway, also worked for the company and later became a Member of Parliament.

The company continued to grow. In 1901, they expanded their Knott Mill factory to build 'high-speed engines'. They worked on very large engines for iron and steel factories, including one with a huge 45-ton flywheel!

Charles John Galloway died in 1904. The Galloway boiler was still being improved, with new features like superheaters added in 1902 and 1910.

The company faced some challenges. In 1912, they went into receivership, which means a manager was appointed to handle their finances, even though the business was doing better. This was due to a plan to issue new shares that would affect existing shareholders.

In 1925, the company was restructured. The next year, they bought the designs and patterns from another company, John Musgrave & Sons, which had closed.

Many engineering companies in Manchester struggled between 1899 and 1939, especially those that made textile machinery and boilers. Companies that focused on new, mass-produced goods for the local market did better.

Galloways Ltd. went into receivership again in 1932. In 1933, another company, Hick, Hargreaves & Co, bought all of Galloway's records, drawings, and designs. This marked the end of W & J Galloway & Sons.

Galloway Boiler and Tubes: Key Inventions

The Galloway company was famous for its inventions related to boilers.

Galloway Tube

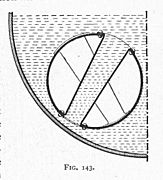

In 1848, Galloways patented the Galloway tube. This was a special tapered (narrower at one end) metal tube that they put inside the furnace of a Lancashire boiler. These tubes helped water circulate better and increased the heating surface, making the boiler more efficient. They were tapered just to make them easier to install.

Galloway Boiler

Following the tubes, in 1851, they introduced the Galloway boiler. In this design, the two furnace flues (the paths for hot gases) of a Lancashire boiler were combined into one wide flue. Many conical (cone-shaped) vertical Galloway tubes were riveted into this wide flue. This design greatly improved how water moved around inside the boiler and made the heating process much more effective.

Images for kids

-

W & J Galloway 600hp cross-compound steam engine with drop-inlet valves and a uniflow low-pressure cylinder. This engine was installed in a cotton mill in 1926 and is now at the Museum of Science & Industry (MOSI) in Manchester.