Steam locomotive facts for kids

A steam locomotive is a special type of train engine that uses the power of expanding steam to move itself and other train cars. It works by burning fuel like coal or oil to heat water in a large tank called a boiler. When the water gets hot enough, it turns into steam, which takes up much more space. This expanding steam pushes pistons, which are connected to the train's wheels, making the locomotive move.

Most steam locomotives carry their fuel and water with them, either directly on the engine or in a special car called a tender. While most use pistons, some rare designs use steam turbines or get their steam from outside sources.

Steam locomotives first appeared in the United Kingdom in the early 1800s. They were the main way to power trains until the mid-1900s. Richard Trevithick built one of the first working steam locomotives in 1804. Later, in 1825, George Stephenson's Locomotion No. 1 carried passengers on a public railway for the first time. This led to quick improvements, and by 1830, the Liverpool and Manchester Railway opened, showing how useful steam trains could be.

Some steam locomotives were incredibly fast, like the LNER Class A4 4468 Mallard, which reached a record-breaking speed of 126 mph (203 km/h) in 1938. Others were huge and powerful, like the Union Pacific Big Boy in the United States, which weighed 540 tons and could pull massive loads.

Starting in the early 1900s, electric and diesel locomotives began to replace steam engines because they were more efficient. By the 1980s, most steam locomotives were no longer used for regular service. However, many are still loved and run today on special tourist and heritage railways.

Contents

- The Story of Steam Trains

- How a Steam Locomotive Works

- Special Features and Tools

- Water Pumps and Injectors

- Boiler Insulation

- Safety Valves

- Pressure Gauge

- Spark Arrestors and Smokeboxes

- Stokers

- Feedwater Heating

- Condensers and Water Supply

- Braking Systems

- Lubrication: Keeping Things Smooth

- Blower: Keeping the Fire Alive

- Buffers and Pilots

- Headlights

- Bells and Whistles

- Automatic Control Systems

- Booster Engines

- Firedoor

- Different Kinds of Steam Locomotives

- How Steam Locomotives are Classified

- Building Steam Locomotives

- The End of Steam Trains

- The Return of Steam: Modern Projects

- Environmental Impact of Steam Trains

- See also

The Story of Steam Trains

Early Days in Britain

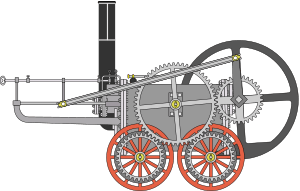

Before steam, horses pulled carts on rail tracks. In 1784, a Scottish inventor named William Murdoch made a small model of a steam-powered road vehicle. Later, in 1802, Richard Trevithick built the first full-size steam locomotive. It was called the Coalbrookdale Locomotive.

On February 21, 1804, another of Trevithick's locomotives made history. It pulled a train carrying iron from a factory in South Wales. This was the first time a steam engine was recorded pulling a load on a railway. Trevithick's designs were important because they used high-pressure steam, making the engines lighter and more powerful.

In 1812, Matthew Murray built Salamanca, the first commercially successful steam locomotive. It used a special gear system to climb hills. Another famous early engine was Puffing Billy, built in 1813–1814. It is one of the oldest preserved locomotives in the world.

George Stephenson's Innovations

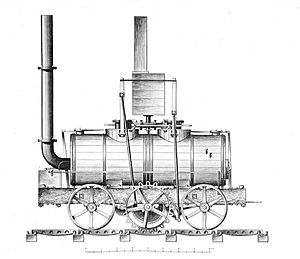

George Stephenson, a former miner, became a key figure in steam train development. In 1814, he built Blücher. In 1825, Stephenson built Locomotion No. 1 for the Stockton and Darlington Railway. This was the world's first public railway to use steam power for passengers.

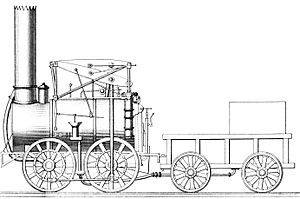

His son, Robert, built The Rocket in 1829. This locomotive won the famous Rainhill Trials, proving that steam engines could be fast and reliable. This success led to the opening of the Liverpool and Manchester Railway in 1830, the first inter-city railway to use only steam power. The Stephenson family's company became a leading builder of steam locomotives worldwide.

Steam Trains in the United States

Early American railroads often imported locomotives from Britain, like the Stourbridge Lion and the John Bull. However, American engineers soon started building their own. In 1830, Peter Cooper designed the Tom Thumb for the Baltimore and Ohio Railroad. It was the first commercial US-built locomotive to run in America. Another important early engine was the DeWitt Clinton in 1831.

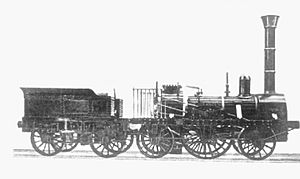

Steam Trains in Europe

Outside the UK and North America, the first railway service opened in France in 1829. It started with animal power but switched to steam in 1831. Belgium's first steam locomotive, The Elephant, ran in 1835.

In Germany, the first working steam locomotive was built in 1816 by Johann Friedrich Krigar. It was similar to the Salamanca. In 1835, the Adler became the first steam train to run between two cities in Germany.

Russia's first steam locomotive was built by the Cherepanovs in 1834. Austria's first steam railway opened in 1837. The oldest continuously working steam engine in the world, the GKB 671, built in 1860, still runs in Austria for special trips.

Steam Trains in Australia

Australia faced unique challenges, especially in dry areas. The water available for locomotive boilers often contained high levels of minerals. This caused problems and reduced the lifespan of the boilers. Because of this, about half of a train's load was often just water for the engine. This led Australian railways to adopt diesel-electric locomotives earlier than some other places.

How a Steam Locomotive Works

A steam locomotive has many parts that work together to make it move. Let's look at the main ones.

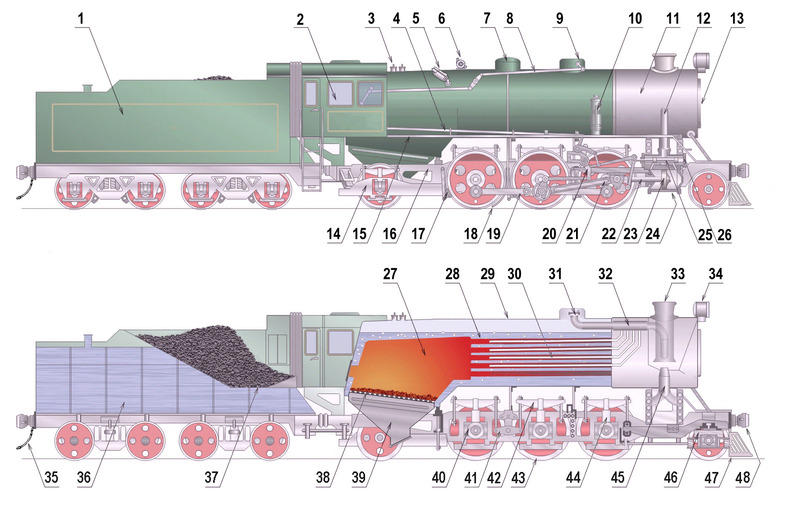

| Key to numbered components | |||||||

|---|---|---|---|---|---|---|---|

| No. | Item | No. | Item | No. | Item | No. | Item |

| 1 | Tender | 13 | Smokebox door | 25 | Valve | 37 | Coal bunker |

| 2 | Cab | 14 | Trailing truck / Rear bogie | 26 | Valve chest / Steam chest | 38 | Grate / Fire grate |

| 3 | Safety valves | 15 | Running board / Foot board | 27 | Firebox | 39 | Ashpan hopper |

| 4 | Reach rod | 16 | Frame | 28 | Boiler tubes | 40 | Journal box |

| 5 | Whistle | 17 | Brake shoe | 29 | Boiler | 41 | Equalising beams / Equalising levers / Equalising bars |

| 6 | Generator / Turbo generator | 18 | Sand pipe | 30 | Superheater tubes | 42 | Leaf springs |

| 7 | Sand dome | 19 | Side rods / Coupling rods | 31 | Regulator valve / Throttle valve | 43 | Driving wheel / Driver |

| 8 | Throttle lever / Regulator lever | 20 | Valve gear / Motion | 32 | Superheater | 44 | Pedestal / Saddle |

| 9 | Steam dome | 21 | Connecting rod / Main rod | 33 | Smokestack / Chimney | 45 | Blast pipe |

| 10 | Air pump / Compressor | 22 | Piston rod | 34 | Headlight | 46 | Pilot truck (pony truck if single axle) / Leading bogie |

| 11 | Smokebox | 23 | Piston | 35 | Brake hose | 47 | Pilot / Cowcatcher |

| 12 | Steam pipe | 24 | Cylinder | 36 | Water compartment | 48 | Coupler / Coupling |

| Descriptions of these components are here. | |||||||

The Boiler: Making Steam Power

The boiler is like the heart of the steam locomotive. It has a firebox where fuel (coal, wood, or oil) burns. This heat turns water into steam in the main barrel of the boiler.

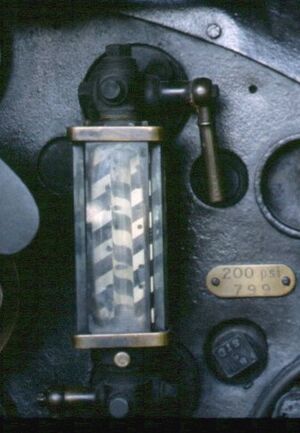

The hot gases from the fire travel through many tubes inside the boiler. These tubes heat the water, turning it into high-pressure steam. The steam pressure is carefully watched with a gauge in the cab. If the pressure gets too high, a safety valve opens automatically to release some steam. This prevents dangerous accidents.

The used steam from the engine shoots up the chimney. This creates a strong draft that pulls air through the fire, keeping it burning hot. This is why steam locomotives make that famous "chuffing" sound!

The steam isn't just for moving the train. It also powers the whistle, the air compressor for the brakes, and pumps to refill the boiler with water. Locomotives need a lot of water, so they often stop to refill their tanks.

It's very important to keep the right amount of water in the boiler. Too little water can cause serious damage. A special device called a fusible plug melts if the water level gets too low, releasing steam to warn the crew.

The Steam Circuit: Moving the Wheels

Steam from the boiler goes into a steam dome and then through a valve called the regulator. This valve controls how much steam goes to the engine. Sometimes, the steam first passes through a superheater to make it even hotter and more efficient.

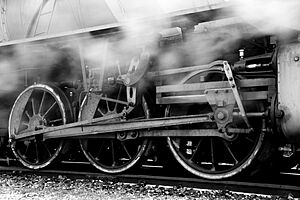

The steam then enters cylinders next to the wheels. Inside each cylinder, steam pushes a piston back and forth. These pistons are connected to the main driving wheels by rods.

Steam is let into each side of the piston alternately, pushing it in one direction, then the other. This back-and-forth motion turns the wheels. The driving wheels are connected by coupling rods, so they all turn together. The way the cranks are set ensures that the locomotive can always start moving.

A system of rods and linkages, called the valve gear, controls when steam enters and leaves the cylinders. The driver can adjust this system to control the train's power and speed. For example, using less steam per push saves fuel when cruising.

After pushing the pistons, the used steam is sent up the chimney through a blastpipe. This creates the "chuffing" sound and helps pull air through the fire, as mentioned before.

Running Gear: Wheels and Suspension

The running gear includes the wheels, axles, brakes, and suspension. These parts connect the power from the pistons to the rails. They also help the locomotive handle curves and bumps on the track.

The weight on the driving wheels is important for grip, or "adhesion," on the rails. To help guide the locomotive around curves and keep it stable at speed, many trains have unpowered wheels at the front (leading wheels) and back (trailing wheels).

Chassis: The Locomotive's Backbone

The chassis, or frame, is the main structure that holds the boiler and all the running gear. The boiler is firmly attached at the front, but at the back, it can slide a little. This allows for expansion when the boiler gets hot.

European locomotives often use "plate frames," which are two flat metal plates. American locomotives often used "bar frames" or large cast-steel frames that combined many parts into one strong structure.

Fuel and Water: Keeping the Engine Going

Large locomotives usually have a tender car attached behind them. This tender carries the water and fuel (coal or oil). Smaller locomotives, called tank locomotives, carry their fuel in a bunker and water in tanks around the boiler.

The type of fuel used depended on what was available. Coal was common in Europe and the UK. In the US, wood was used early on, but coal became more popular. Some railways even burned bagasse (a byproduct of sugar cane) or oil.

Water is vital for steam locomotives. They use a lot of it because the steam is released after one use. Water was supplied at special stopping places or from water towers. Some main lines had "water troughs" between the rails. Locomotives could scoop up water while moving, saving time.

Crew: The People Who Run the Train

A steam locomotive usually needs at least two people to operate it. The train driver (or engineer in North America) controls the train's speed, starting, and stopping. The fireman is in charge of keeping the fire burning, managing steam pressure, and watching the water levels in the boiler and tender. They work together in the cab, which protects them from the weather.

Special Features and Tools

Steam locomotives have many tools and devices to help them run safely and efficiently.

Water Pumps and Injectors

Water must be constantly added to the boiler to replace the steam used. Since the boiler is under high pressure, the water needs to be forced in. Early trains used hand pumps. Later, pumps driven by the engine's motion (axle pumps) were used.

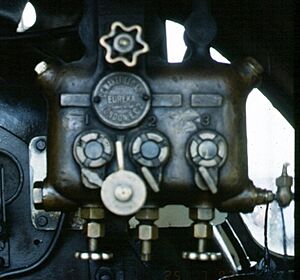

Most modern steam locomotives use steam injectors. These clever devices use steam from the boiler to push water into the boiler, even against the high pressure. Usually, two independent systems are in place for safety.

Glass tubes called water gauges show the water level in the boiler. The crew must watch these carefully. Two gauges are often installed to provide reliable readings.

Boiler Insulation

To prevent heat from escaping, the boiler is covered with insulating material, called "lagging." Early locomotives used wooden strips. Later, materials like magnesia blocks or glass wool were used. This insulation helps the boiler stay hot and saves fuel. A metal casing, called boiler clothing, protects the lagging.

- Lagging on Early Steam Locomotives

Safety Valves

Safety valves are crucial for preventing the boiler from exploding due to too much pressure. Early valves used weights, but these could bounce. Later, spring-loaded valves were developed. Modern safety valves, like the Richardson type, are designed to open precisely when the pressure reaches its maximum safe limit.

Pressure Gauge

Early locomotives didn't have clear pressure gauges. George Stephenson used a tall mercury tube for his Rocket. In 1849, the Bourdon tube gauge was invented. This type of gauge, which uses a coiled tube that straightens with pressure, quickly became standard and is still used today.

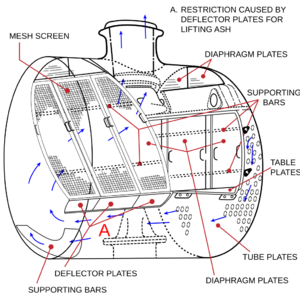

Spark Arrestors and Smokeboxes

Locomotives burning wood or coal can send out sparks. Spark arrestors, often built into the smokestack, catch these sparks to prevent fires. Early designs included cone-shaped deflectors and wire screens. More advanced "self-cleaning smokeboxes" broke larger particles into tiny pieces that would be ejected safely.

Stokers

For very large locomotives, a fireman couldn't shovel coal fast enough to keep the fire going. Mechanical stokers, powered by steam, were developed to automatically feed coal into the firebox. These became standard on many big engines.

Feedwater Heating

Adding cold water to a hot boiler can reduce its power. To improve efficiency, many locomotives used feedwater heaters. These systems used some of the engine's exhaust steam to warm the water before it entered the boiler. This also helped prevent "thermal shock" to the boiler.

Condensers and Water Supply

Steam locomotives use a lot of water. In dry areas, this was a big problem. Condensing engines were designed to recycle their steam. Instead of releasing steam into the air, it was sent to large radiators in the tender to turn back into water. These were used in places like the Karoo desert in South Africa.

Some locomotives could scoop water from "water troughs" while moving, avoiding stops. In the US, small towns without water facilities were called "jerkwater towns" because crews would stop and "jerk water" from streams with buckets.

Braking Systems

Steam locomotives have their own brakes, usually large shoes that press against the driving wheels. They also have a handbrake. For the whole train, two main types of brakes were used: air brakes and vacuum brakes.

Air brakes use a steam-powered air compressor to create compressed air for the brake system. Vacuum brakes use a steam-operated ejector to create a vacuum. Air brakes were common in most countries, while vacuum brakes were popular in the UK and places like India and South Africa.

Sandboxes on the locomotive drop sand onto the rails. This helps the wheels get better grip for starting, stopping, or climbing hills, especially in wet or icy conditions.

Lubrication: Keeping Things Smooth

Moving parts like pistons and valves need lubrication to work smoothly. Early methods involved dropping tallow into the engine. Later, more advanced systems were developed to inject thick mineral oil into the steam supply. These systems often used a mechanical pump or a displacement lubricator to ensure a steady supply of oil.

Other parts, like axle bearings, were lubricated using oil reservoirs with worsted yarn wicks. These wicks drew oil to the moving parts through capillary action.

Blower: Keeping the Fire Alive

When a locomotive is stopped or coasting, there's no exhaust steam to create a draft for the fire. A "blower" is used then. It's a ring with small steam nozzles that shoot steam up the chimney, keeping the fire burning. It's important to open the blower before closing the main steam valve to prevent hot gases from blowing back into the cab.

Buffers and Pilots

In Europe, locomotives usually have buffers at each end. These absorb bumps and help connect the train cars. In North America, a Janney coupler handles all the forces between the locomotive and cars.

A pilot, often called a "cowcatcher," was usually fixed to the front of American locomotives. These plough-shaped devices were designed to clear obstacles like animals or tree branches from the track.

Headlights

When trains started running at night, locomotives needed lights. Early headlights were oil or acetylene lamps. By the late 1880s, bright electric arc lamps became common in the US. In Britain, less intense oil lamps were used to avoid affecting night vision and signal visibility.

Bells and Whistles

Whistles and bells have been used on locomotives since the beginning. Bells warn people when a train is moving, especially in places like the US, India, and Canada. Whistles are used to signal other personnel and give warnings. The sound of the whistle could be designed for long distances or for local use, depending on the area.

Automatic Control Systems

In the early 1900s, some countries like Germany and Britain started using Automatic Warning System (AWS) in-cab signaling. These systems automatically applied the brakes if a signal was passed at "caution," improving safety.

Booster Engines

A booster engine was a small extra steam engine, usually on the trailing wheels. It provided extra pulling power for starting heavy trains. It would switch off at low speeds, like 30 km/h (19 mph). Boosters were common in the US.

Firedoor

The firedoor covers the opening to the firebox when coal isn't being added. It helps control the airflow to the fire and protects the crew from hot gases blowing back into the cab. Some firedoors slide open, while others pivot.

Different Kinds of Steam Locomotives

Engineers created many variations to improve how steam locomotives worked.

Cylinders

Most early steam locomotives had two cylinders, one on each side. These could be "inside" the main frame or "outside" the frame. Later designs used three or four cylinders for more even power, but these were more complex to maintain.

Articulated Locomotives

Very powerful locomotives tend to be long. But long, rigid trains struggle on tight curves, especially on narrow-gauge railways. Articulated designs solved this. The Mallet and Garratt were popular types. They had a single boiler but two separate engine units (cylinders and driving wheels) that could swivel, allowing the train to bend around curves.

Geared Locomotives

For jobs needing high pulling power at very low speeds, like in industrial areas or logging railways, "geared" steam locomotives were developed. Types like the Shay, Climax, and Heisler used gears to allow the engine to run faster than the driving wheels, providing more torque.

Cab Forward Designs

On the Southern Pacific Railroad in the United States, a unique design called "cab forward" was used. The cab and firebox were at the front, and the tender was behind the smokebox. This allowed the engineer to breathe air free of smoke when going through long mountain tunnels. This was only possible because these trains burned oil, not coal.

Steam Turbines

Some engineers tried using steam turbines instead of pistons to power locomotives. These experiments were mostly unsuccessful due to issues like dust, vibration, and inefficiency at lower speeds. However, a few designs, like the TGOJ MT3 in Sweden, worked well for hauling iron ore.

Fireless Locomotives

A fireless locomotive doesn't have a firebox. Instead, it has a special tank called a steam accumulator that is filled with steam from a stationary boiler. These were used in places where fire was a big risk, like oil refineries, or where cleanliness was important, like food factories.

How Steam Locomotives are Classified

Wheel Arrangement Notation

Steam locomotives are categorized by how their wheels are arranged. The most common system is the Whyte notation. It uses numbers to show the wheels: first, the number of unpowered leading wheels, then the number of driving wheels, and finally, the number of unpowered trailing wheels. For example, a 4-6-2 locomotive has 4 leading wheels, 6 driving wheels, and 2 trailing wheels. Different arrangements often got names, like "Santa Fe" for the 2-10-2 type.

Building Steam Locomotives

Most Common Types Built

The most-produced single class of steam locomotive in the world is the 0-10-0 Russian locomotive class E, with about 11,000 built. Germany's DRB Class 52 2-10-0 Kriegslok also saw around 7,000 units produced.

Manufacturing in the United Kingdom

Before 1923, many large British railway companies built their own locomotives. Smaller companies bought them from outside builders. Between 1923 and 1947, the "Big Four" railway companies continued to build most of their own. British Railways (BR) continued building new steam locomotives until 1960, with the last one named Evening Star.

Today, a few specialized companies still build small locomotives for tourist railways. In 2008, a new main line steam locomotive, 60163 Tornado, was completed and began service on UK main lines.

Manufacturing in the United States

Most American locomotives were built in the United States. Early on, American railroads needed engines that were tough and could travel long distances over less perfect tracks. Large manufacturers like Baldwin Locomotive Works, American Locomotive Company (ALCO), and Lima Locomotive Works built locomotives for almost all rail companies. Between 1830 and 1950, over 160,000 steam locomotives were built in the US.

Steam locomotives needed regular maintenance and overhauls. Parts were often upgraded or replaced. When repairs became too expensive, the locomotive was retired.

Manufacturing in Australia

In Australia, companies like Clyde Engineering and the Eveleigh Railway Workshops built steam locomotives for the New South Wales Government Railways. Other states also had local workshops that built their own engines. For example, Victorian Railways built many locomotives at its Newport Workshops, including the huge H class 4-8-4.

The End of Steam Trains

The arrival of electric trains around 1900 and later diesel locomotives marked the beginning of the end for steam locomotives. Diesel power became more reliable in the 1930s, and by the 1950s, North America had largely switched away from steam. In Europe, electrification replaced steam by the 1970s.

Steam engines are less efficient than modern diesels. They need constant maintenance and a lot of labor. Finding water was a big problem in dry areas. The water could also be "hard," causing mineral deposits (scale) in the boiler, which reduced efficiency and damaged parts.

Raising steam from coal took hours and created a lot of pollution. Diesel or electric locomotives were much cleaner and easier to start. The smoke from steam locomotives was also a concern, leading to the development of cleaner alternatives.

The Return of Steam: Modern Projects

The rising cost of diesel fuel has led to new ideas for bringing back steam power. While no new steam locomotives are being mass-produced for regular service, many are still used on tourist and heritage railways around the world.

Since the 1970s, railway fans in the UK have been building new steam locomotives. For example, the standard-gauge LNER Peppercorn Pacific "Tornado" was completed in 2008 and now runs on main lines. Many other projects are underway to build working replicas of famous old steam engines.

In the US, the Coalition for Sustainable Rail (CSR) is working on a modern, high-speed steam locomotive. They aim to use environmentally friendly fuel made from plant material. Their "Project 130" hopes to create a locomotive capable of speeds up to 130 mph (209 km/h), potentially breaking the world speed record for steam trains.

The town of Wolsztyn, Poland, is unique. It is the last place in the world where you can ride a regularly scheduled passenger train pulled by steam power. Several working locomotives run daily commuter services there.

The Swiss company Dampflokomotiv- und Maschinenfabrik DLM AG built eight new steam locomotives for mountain railways in Switzerland and Austria between 1992 and 1996. They also rebuilt a German locomotive with modern improvements like roller bearings and better insulation.

Environmental Impact of Steam Trains

Steam locomotives release carbon dioxide when they burn fuel. This contributes to climate change. Because of this, the future use of steam locomotives faces challenges. For example, in the UK, new laws against coal mining have made coal more expensive, impacting heritage railways that use coal-fired engines.

To reduce their environmental footprint, many tourist railroads in the US use oil-fired steam locomotives or have converted their engines to run on oil. Some, like the Grand Canyon Railway, even use used vegetable oil as fuel.

The Coalition for Sustainable Rail (CSR) is developing an eco-friendly coal substitute from torrefied biomass (treated plant material). Tests in 2019 showed positive results, with the biofuel burning hotter and faster than coal. This project aims to provide a sustainable fuel for historic steam locomotives and potentially offer an environmentally better alternative to diesel trains in the future.

See also

In Spanish: Locomotora de vapor para niños

In Spanish: Locomotora de vapor para niños

General

- History of rail transport

- Live steam

- Reciprocating motion

- Timeline of railway history

- Dieselisation

Types of Steam Locomotives

- Articulated locomotive

- Garratt locomotive

- Fairlie locomotive

- Mallet locomotive

- Cab forward locomotive

- Compound locomotive

- Duplex locomotive

- Electric–steam locomotive

- Geared steam locomotive

- Heilmann locomotive

- High-pressure steam locomotive

- Steam dummies and Steam trams

- Steam turbine locomotive

- Streamliner

- Tank locomotive

- Triplex locomotive

- Whyte Notation

| Ernest Everett Just |

| Mary Jackson |

| Emmett Chappelle |

| Marie Maynard Daly |