Connecting rod facts for kids

A connecting rod, often called a 'con rod', is a very important part inside an engine. It connects the piston to the crankshaft. Think of it like your arm connecting your hand (the piston) to a bicycle pedal (the crankshaft).

Together, the connecting rod and the crankshaft work to change the up-and-down motion of the piston into the spinning motion of the crankshaft. This is how engines create power to move things like cars or trains! The connecting rod has to be super strong because it pushes and pulls the piston with a lot of force.

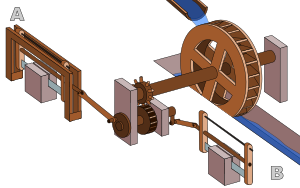

The idea of a connecting rod isn't new! Long ago, similar parts were used in water mills to change the spinning motion of a water wheel into a back-and-forth movement.

Most often, you'll find connecting rods in internal combustion engines (like in cars) or in steam engines.

Contents

How Connecting Rods Started

Believe it or not, a very old version of a connecting rod and crank was found in France, dating back to 69 BC!

Even before that, ancient Roman watermills used a similar mechanical part. For example, at the Hierapolis sawmill in what is now Turkey, and at sawmills in Ephesus and Gerasa, people used cranks and connecting rods. These machines turned the spinning of a waterwheel into the back-and-forth movement needed to power saw blades.

Later, between 1174 and 1206 AD, a clever inventor named Al-Jazari from the Artuqid State (also in modern Turkey) described a machine that used a connecting rod with a crankshaft to pump water. This showed how the design was developing. You can also see drawings of cranks with connecting rods in the notebooks of Taccola from Renaissance Italy and in paintings by Pisanello from the 15th century.

Connecting Rods in Steam Engines

The very first steam engine, the 1712 Newcomen atmospheric engine, didn't use a connecting rod. It used chains because its piston only pushed in one direction. But most steam engines that came after it were "double-acting." This means the piston pushed in both directions (up and down), so a connecting rod was needed.

In these engines, there's often a special sliding part called a crosshead. The connecting rod connects to this crosshead, which then connects to the piston. This setup helps keep everything moving smoothly.

For steam locomotives, the connecting rods are usually connected directly to the large driving wheels. They link the crank pin on the wheel to the crosshead, which is attached to the piston rod. On smaller steam locomotives, these rods are often rectangular.

On paddle steamers (boats with big paddle wheels), the connecting rods have a special name: 'pitmans'.

Connecting Rods in Car Engines

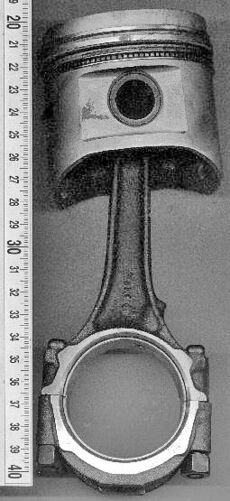

A connecting rod in a car engine has three main parts:

- The big end is the larger, round end.

- The small end is the smaller end.

- The rod is the long part in between.

The small end connects to the gudgeon pin (also called a 'piston pin'). This pin lets the connecting rod and the piston rotate a little bit as they move.

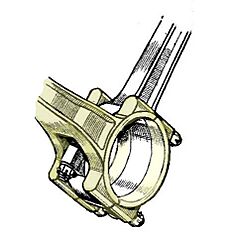

The big end connects to the crankpin on the crankshaft. It usually has a special plain bearing inside to reduce friction and help it spin smoothly. Some smaller engines might use a different type of bearing that doesn't need as much oil.

Most connecting rods have a tiny hole drilled through the big end. This hole squirts lubricating oil onto the cylinder walls. This oil helps the pistons and piston rings slide easily up and down without wearing out.

Because the connecting rod can rotate at both ends, its angle changes as the piston moves up and down and the crankshaft spins. This flexible connection is key to how an engine works!

What Connecting Rods Are Made Of

Connecting rods are made from many different materials. For most cars, they are usually made of strong steel.

For high-performance engines, like in race cars, special "billet" connecting rods are used. These are made by carving them out of a solid block of metal, making them extra strong.

Other materials include special kinds of aluminum or aluminum alloys. These are lighter and can absorb strong impacts, but they might not last as long. Titanium is another option that is very light but also very expensive. For cheaper, smaller engines like those in motor scooters, Cast iron can be used.

Why Connecting Rods Can Fail

Every time the crankshaft spins, a connecting rod faces huge, repeated forces. It gets pushed and pulled very hard. These forces get much bigger as the engine spins faster.

When a connecting rod breaks, it's often called "throwing a rod." This can be a big problem because the broken rod can smash through the side of the engine block, ruining the engine.

Common reasons for a connecting rod to break include:

- Breaking from too much pulling force at very high engine speeds.

- Hitting a valve if something goes wrong with the engine's valves.

- Problems with the rod's bearing, often due to not enough oil.

- Being installed incorrectly.

How Connecting Rods Affect Engine Wear

The connecting rod pushes the piston sideways against the cylinder wall. This sideways force can cause the cylinders to wear into an oval shape over time. When cylinders become oval, the round piston rings can't seal properly, which makes the engine lose power.

The amount of sideways push depends on the angle of the connecting rod. Longer connecting rods create less sideways force, which means less wear on the engine. However, there's a limit to how long a connecting rod can be. It has to fit inside the engine block, and the piston can't travel too far up!

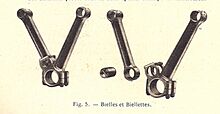

Special Rods: Master-and-Slave

Some engines, like Radial engines (which have cylinders arranged in a circle), use a special setup called "master-and-slave" connecting rods. One piston has a main "master" rod that connects directly to the crankshaft. All the other pistons have "slave" rods that connect to rings around the master rod.

Engines with many cylinders, like V12 engines, sometimes use master-and-slave rods too. This helps save space on the crankshaft. However, a small problem with this design is that the "slave" pistons might move slightly differently than the "master" piston, which can cause a bit more vibration.

One of the most complex examples was the 24-cylinder Junkers Jumo 222 airplane engine from World War II. It had six groups of cylinders, and each group used one master connecting rod with five slave rods!

Special Rods: Fork-and-Blade

"Fork-and-blade" rods are another special type, used in engines like V-twin motorcycles and V12 aircraft engines. For each pair of cylinders, one rod is shaped like a "fork" with a gap in the middle. The other rod, called the "blade" rod, is thinner and fits into this gap. This design helps the engine run more smoothly by preventing certain wobbling motions.

In this setup, the "fork" rod often has a wide bearing sleeve. The "blade" rod then runs on the outside of this sleeve, not directly on the crankshaft. This makes the rods move back and forth against each other, which is different from a normal spinning motion. This can be tricky for lubrication, but it reduces other forces.

Famous engines that used fork-and-blade rods include the Rolls-Royce Merlin V12 aircraft engine, some EMD Diesel engines, and several Harley Davidson V-twin motorcycle engines.

See also

- Hydrolock

- List of auto parts

- Steam locomotive components