Newcomen atmospheric engine facts for kids

The atmospheric engine was a very important invention by Thomas Newcomen in 1712. People often called it the Newcomen fire engine or simply a Newcomen engine. This amazing machine used steam to create a powerful force. It worked by letting steam into a large cylinder. Then, cold water was sprayed inside, which turned the steam back into water. This created a strong pull, like a vacuum, inside the cylinder. The air pressure from outside then pushed a piston down, making the engine move.

This engine was a huge step forward because it was the first practical machine to use steam to do real mechanical work. Newcomen engines were used all over Britain and Europe, mostly to pump water out of mines. Hundreds of these engines were built during the 1700s.

Later, James Watt made a much better steam engine. His design used about half as much fuel as Newcomen's engine. Many old Newcomen engines were changed to Watt's design. Because of his improvements, James Watt is often more famous than Newcomen when people talk about the start of the steam engine.

Contents

Early Steam Ideas

Before Newcomen, some people had tried to make small devices that used steam. Most of these were just interesting toys. Around 1600, some inventors used steam to power small fountains. These worked a bit like a coffee percolator. Water was heated in a container until it boiled and made steam. The steam pushed the water up a pipe and out of a nozzle. These early devices weren't very powerful, but they showed that steam could be used to create movement.

In 1606, a Spaniard named Jerónimo de Ayanz y Beaumont got a patent for a steam-powered water pump. This pump was successfully used to drain flooded mines in Guadalcanal, Spain.

In 1662, Edward Somerset, 2nd Marquess of Worcester, wrote a book with some of his inventions. One idea was a steam-powered pump for fountains. This machine used both a partial vacuum and steam pressure. It had two containers that were filled with steam. Then, cold water was sprayed on them, which made the steam turn back into water. This created a partial vacuum that pulled water up from a well into the container. Fresh steam pressure then pushed the water from the container up another pipe to a higher tank. By using the two containers one after the other, water could be pumped continuously.

Savery's "Miner's Friend" Pump

In 1698, Thomas Savery patented a steam-powered pump he called the "Miner's Friend." This pump was very similar to Somerset's design. Savery later added a way to spray cold water on the outside of the container to make the steam cool down faster.

Savery's invention wasn't really a "steam engine" because it didn't have moving parts that could transfer power to other machines. People had high hopes for the Miner's Friend. Parliament even extended Savery's patent for 21 more years, until 1733. However, Savery's device didn't work as well as everyone hoped.

One problem was that a vacuum can only lift water about 30 feet (9 meters). Steam pressure could add another 40 feet (12 meters) or so. This wasn't enough to pump water out of deep mines. Savery suggested putting the pump on a ledge inside the mine or using several pumps. These were not easy solutions. What was really needed was a mechanical pump at the surface that could lift water directly. Another big problem was that the boiler operated under pressure, and one of Savery's boilers even exploded around 1705.

Denis Papin's Steam Experiment

Denis Papin was a scientist who described an important experiment in 1690. He poured a small amount of water into a tall cylinder. He then put a piston on a rod inside. After removing the air below the piston, he heated the cylinder to boil the water. The steam pushed the piston to the top. The piston was then held in place. When the fire was removed, the cylinder cooled, and the steam turned back into water, creating a vacuum below the piston. A rope attached to the piston rod went over two pulleys, with a weight hanging from the end. When the piston was released, the air pressure pushed it down, lifting a 60-pound (27 kg) weight. Papin's ideas were known to the Royal Society in London, and his 1690 steam engine was similar to the one Thomas Newcomen built later.

How Newcomen's Engine Spread

Newcomen took Papin's ideas and made them work in a practical way. We don't know exactly how he did it. The main challenge was making the engine work over and over again. Newcomen solved this by adding a boiler that continuously supplied steam. He also found a way to condense the steam to create the vacuum and then get rid of the water.

The engine's power piston was hung by chains from one end of a large, rocking wooden beam. This beam was balanced on a strong wall of the engine house. The pump rods hung from the other end of the beam, outside the building. Unlike Savery's pump, Newcomen's engine used steam to lift the heavy pump rods. These rods would then drop down the mine shaft by their own weight, pushing water up from the mine. The boiler made steam at a very low pressure. It was usually placed right under the cylinder or behind a wall with a pipe connecting them. Newcomen was an "ironmonger," or metal merchant, so he knew a lot about what materials would work best for such a machine.

The first successful Newcomen engines were built in 1712 in the Black Country area of England. One famous engine was at the Conygree Coalworks in Tipton. This is generally seen as the first successful Newcomen engine. Another was built near Wolverhampton. Both were used by Newcomen and his partner John Calley to pump water out of coal mines. You can see a working copy of this engine at the nearby Black Country Living Museum.

Another Newcomen engine was working in Cornwall by 1715. Soon, mines all over England wanted these engines. Since Savery's patent was still active, Newcomen had to work with Savery and use his patent. Later, the patent belonged to a company called The Proprietors of the Invention for raising water by fire.

Even though they were first used in coal mines, Newcomen's engines also helped pump water out of metal mines, like the tin mines in Cornwall. By the time Newcomen died, over a hundred of his engines had been installed. They were in the West Country, the Midlands, north Wales, and near Newcastle. A few were also built in other European countries like France, Belgium, Spain, and Hungary. Evidence of a Newcomen engine was even found in Midlothian, VA, USA, where some of the first coal mines were.

How the Engine Worked

Main Parts of the Engine

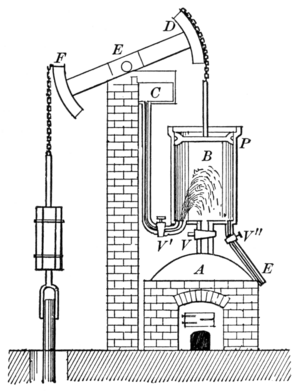

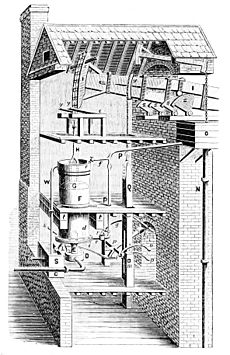

Newcomen's engine looked simple but was quite complex. It had a boiler (marked A in diagrams), usually a haystack boiler, right under the cylinder. This boiler made a lot of very low-pressure steam. Early boilers were made of copper and lead, but later ones were made of riveted iron plates.

The engine's movement was transferred through a large, rocking "Great balanced Beam". This beam was balanced on a strong wall of the engine house. The pump rods hung from one end of the beam (F) outside the building. Inside the building, a piston (P) moved up and down in a cylinder (B). The top of the cylinder was open to the air, and the bottom was connected to the boiler by a pipe. Early cylinders were made of brass, but cast iron was found to be better and cheaper.

A leather ring sealed the piston, but because the cylinder wasn't perfectly smooth, a layer of water had to be kept on top of the piston. High up in the engine house was a water tank (C) that supplied cold water to cool the steam in the cylinder. This tank also supplied water for the piston seal. Any extra warm water from the seal flowed back to a well or to feed the boiler.

How it Operated

The pump equipment was heavier than the steam piston. So, when the engine was resting, the pump side of the beam was down, and the engine side was up. This was called "out of the house."

To start the engine, a valve (V) was opened, letting steam from the boiler into the cylinder, below the piston. Then, the steam valve was closed, and a water injection valve (V) was quickly opened and shut. This sprayed cold water into the cylinder, which condensed the steam and created a partial vacuum under the piston. The air pressure above the piston then pushed the piston down. This was the powerful "power stroke," which pulled the beam "into the house" and lifted the pump gear.

Next, steam was let back into the cylinder. This destroyed the vacuum and pushed the condensed water out. As the low-pressure steam filled the cylinder, the weight of the pump and gear pulled the beam back to its starting position. At the same time, this action pushed water up from the mine.

This whole cycle repeated about 12 times every minute.

The Snifting Valve

Newcomen found that his first engine would stop working after a while. He discovered that small amounts of air were getting into the cylinder with the steam. Water naturally has some air dissolved in it, and boiling the water released this air. This air couldn't be condensed by the cold water spray and would slowly build up until the engine stopped. To fix this, a special valve called a "snifting clack" or snifter valve was added near the bottom of the cylinder. This valve would open briefly when steam first entered the cylinder, letting out any air. It was called a "snifter" because of the noise it made, "like a Man snifting with a Cold."

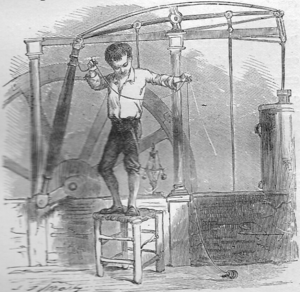

Making it Automatic

In early engines, a person called a plug man had to open and close the valves by hand. But this job needed very precise timing, so people wanted to make it automatic. This was done using a plug tree. This was a vertical beam that hung next to the cylinder. It had special parts that would open and close the valves automatically as the main beam moved up and down.

There's a famous story that in 1713, a young boy named Humphrey Potter, who worked as a cock boy (valve operator), made the engine automatic. He supposedly tied strings from the valves to the moving beam so they would open and close by themselves. However, it's likely that automatic valve systems were already being used before 1715. Pictures from 1717 and 1719 clearly show these automatic systems. Because the engine used so much steam, it had to be stopped and restarted sometimes. Even this process was made automatic using a floating device in a pipe connected to the boiler.

Pumps Used with the Engine

Most pictures of the Newcomen engine only show the engine side, not the pumps. It's believed that early engines used "dead-weight force pumps." This means the engine's job was just to lift the pump side of the beam. Then, the heavy pump rods would fall by gravity, pushing water up. The working replica at the Black Country Living Museum uses this setup and pumps water at the original rate. Later, Watt engines used the engine's stroke to power lift pumps, and some later Newcomen engines might have done this too.

Improvements and Uses

Towards the end of its time, the atmospheric engine was greatly improved by John Smeaton. He built many large Newcomen engines in the 1770s. People also wanted engines that could create a spinning motion, not just up-and-down. Wasborough and Pickard tried to do this by using a Newcomen engine to turn a flywheel with a crank. Pickard got a patent for using a crank with steam engines in 1780. This was a problem for Boulton and Watt, who then invented the sun and planet gear to get around Pickard's patent for their own engines.

By 1725, the Newcomen engine was commonly used in mining, especially in coal mines. It stayed mostly the same for the rest of the century. Newcomen engines were also used to pump water for towns. For example, the first Newcomen engine in France was built in 1726 to pump water from the Seine River to Paris.

The engine was also used to power other machines indirectly. It could pump water from below a water wheel back up to a reservoir above it. This way, the same water could turn the wheel again. An early example of this was at Coalbrookdale. A horse-powered pump there was replaced by a Newcomen engine in 1742–43. Several new furnaces in Shropshire used this method to power their operations. In other industries, engine-pumping was less common, but Richard Arkwright used an engine to help power his cotton mill.

People tried to use Newcomen engines to directly power machinery, but this wasn't very successful. The single power stroke made the motion very jerky.

What Came Next

The biggest problem with the Newcomen engine was that it wasted a lot of energy, making it expensive to run. After the steam was cooled to create the vacuum, the cylinder walls became cold. When new steam entered, some of it would condense on the cold walls instead of filling the cylinder. This meant a lot of fuel was used just to heat the cylinder back up. Larger engines were more efficient because the heat loss was related to the surface area, while the useful work was related to the volume. However, efficiency wasn't a huge concern in coal mines, where coal was cheap and easy to get.

Newcomen's engine was eventually replaced when James Watt improved it in 1769. Watt solved the problem of the cold cylinder walls. In the Watt steam engine, the steam was condensed in a separate unit called a condenser, which was connected to the cylinder by a pipe. When a valve opened, the vacuum in the condenser would pull the steam out of the cylinder. This kept the main cylinder walls hot and greatly reduced fuel use. Watt's design also allowed for a "double-acting cylinder," meaning it had power strokes both when the piston went up and when it went down. This made the engine much more powerful without making it much bigger.

Watt's new design, introduced in 1769, didn't replace all Newcomen engines right away. Watt strongly protected his patents, so people kept using Newcomen engines to avoid paying him royalties. When his patents ran out in 1800, many Watt engines were quickly installed, and Newcomen engines became less common, even in coal mines.

Engines Still Around Today

The Newcomen Memorial Engine can be seen working in Newcomen's hometown of Dartmouth. It was moved there in 1963 by the Newcomen Society. This engine is thought to be from 1725 and was first used at the Griff Colliery near Coventry.

An engine installed in Ashton-under-Lyne around 1760, known as Fairbottom Bobs, is now kept at the Henry Ford Museum in Dearborn, Michigan.

The only Newcomen-style engine still in its original place is at the Elsecar Heritage Centre, near Barnsley in South Yorkshire. This was probably the last Newcomen-style engine used for business, running from 1795 until 1923. The engine, its original shaft, and engine house were fully restored in 2014.

A Newcomen Engine is on display at the Science Museum in London.

Another example is at the National Museum of Scotland. It was originally used at Caprington Colliery in Kilmarnock.

An engine from Farme Colliery is displayed at Summerlee, Museum of Scottish Industrial Life. This one was unusual because it was used for lifting things (winding) instead of pumping water.

In 1986, a full-size working copy of the 1712 Newcomen Steam Engine was built at the Black Country Living Museum in Dudley. It is the only full-size working copy of the engine in the world. This "fire engine" is in an impressive brick building, with a wooden beam sticking out of one wall. Rods hang from the outside end of the beam and work pumps at the bottom of the mine shaft to bring water to the surface. The engine itself is simple, with just a boiler, a cylinder, a piston, and valves. A coal fire heats water in the boiler, which is like a covered pan. The steam then goes into the brass cylinder above the boiler. The cylinder is more than 2 meters (6.5 feet) long and 52 centimeters (20 inches) wide. Cold water is sprayed into the cylinder to condense the steam, creating a vacuum. This vacuum pulls the inner end of the beam down, which makes the pump move.

See also

- Timeline of steam power

- Cataract – a device that controlled the speed of beam engines.

- Atmospheric railway

| Janet Taylor Pickett |

| Synthia Saint James |

| Howardena Pindell |

| Faith Ringgold |