Bessemer process facts for kids

The Bessemer process was a very important way to make steel from hot pig iron. It was the first cheap method for making steel in large amounts. Before this, making steel was much harder and more expensive.

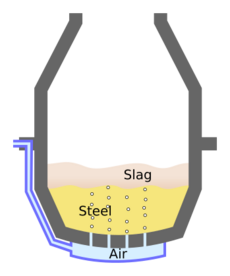

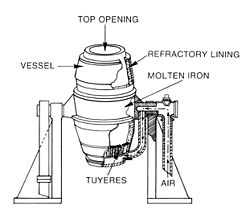

The main idea behind the Bessemer process is to clean the iron by blowing air through it. This air burns away the unwanted stuff, like carbon. This burning also makes the iron very hot, keeping it melted.

People outside Europe had used similar ways to clean iron for hundreds of years. For example, in the 11th century, a Chinese scholar named Shen Kuo wrote about a similar method. In the 1600s, European travelers saw the Japanese using a process like it too.

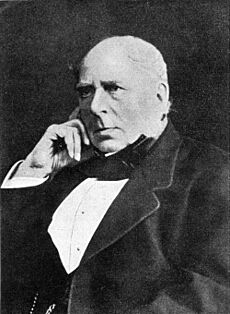

The modern Bessemer process is named after its inventor, Henry Bessemer, from England. He got a patent for his method in 1856. Some people say an American inventor, William Kelly, discovered a similar process in 1851. But this is still debated.

There's also a version called the "basic Bessemer process." This uses a special lining inside the machine. It was discovered by Percy Gilchrist and Sidney Gilchrist Thomas.

Contents

History

Early Ways to Make Steel

China's Early Methods

A method similar to the Bessemer process existed in East Asia around the 11th century. During China's Song Dynasty (960–1279 CE), people found a way to remove some carbon from cast iron. They did this by repeatedly shaping the iron while blowing cold air on it.

Historians like Joseph Needham say this method was like an early version of the Bessemer process. The scholar Shen Kuo described it in 1075. This method was likely first used in the iron-making areas near the Henan and Hebei borders.

Europe's Early Methods

In the 1400s, Europe developed the finery forge process. This method also used air blowing to refine iron. Later, in 1740, Benjamin Huntsman created the crucible technique in Sheffield, England. This greatly improved how much and how well steel could be made. But it was different from the Bessemer process.

The Japanese might have used a Bessemer-like process. European travelers saw this in the 1600s. An adventurer named Johan Albrecht de Mandelslo described it in a book from 1669. He wrote that the Japanese could melt iron without fire. They used a special container and blew air through it. Historians think Mandelslo heard about this from others.

Bessemer's Invention

In the 1850s, an American inventor named William Kelly worked on a similar method. Some believe Kelly learned from Chinese ironworkers he hired in 1854. It's still debated if Kelly and Bessemer invented the same process on their own.

When Bessemer's patent was announced, Kelly wrote to a magazine. He said he had experimented with the process earlier. He also thought Bessemer might have known about his discovery. Kelly's process, however, was thought to be less developed than Bessemer's.

Sir Henry Bessemer wrote about how he got the idea in his autobiography. During the Crimean War, many inventors wanted to improve military technology. Bessemer said his idea came from talking with Napoleon III in 1854. Napoleon III wanted better steel for cannons.

Bessemer decided to try and make better iron for guns. At that time, steel was too expensive for large items like cannons. In 1855, he started working on making steel in huge amounts. He filed his first patent for the Bessemer process in October 1855. He officially patented the method in 1856. William Kelly was given an earlier patent date in 1857.

Bessemer allowed four companies to use his patent. But the steel they made wasn't good enough. It was "rotten hot and rotten cold," meaning it broke easily. Bessemer bought back the licenses. He realized the problem was impurities in the iron. He needed to know exactly when to stop blowing air. This would burn off impurities but leave the right amount of carbon.

He spent a lot of money trying to find the answer. But he couldn't. Some types of steel are also affected by the nitrogen in the air blast.

The solution came from an English metallurgist named Robert Forester Mushet. He found a way to burn off almost all impurities and carbon first. Then, he added back exact amounts of carbon and manganese. He used a special alloy called spiegeleisen. This made the steel much better and stronger. It could be shaped and used for many things. Mushet's patent eventually ran out, and Bessemer bought it. Bessemer earned over $5 million from his patents.

The first company to use the process was W & J Galloway in Manchester. They started making steel in Sheffield in 1858. They used iron from Sweden. This was the first time Bessemer steel was made for sale.

A Swedish trader, Göran Fredrik Göransson, also bought a share of the patent in 1857. He experimented with the process in Sweden and finally succeeded in 1858. He then convinced Bessemer of his success. Göransson built a new factory in 1862. This factory grew into the company now known as Sandvik.

Steel in the United States

Alexander Lyman Holley helped make Bessemer steel successful in the United States. In 1862, he visited Bessemer's factory in England. He became interested in bringing the process to the US.

Holley worked with two iron producers from Troy, New York. They got a license to use Bessemer's process. In 1865, they started building a steel mill in Troy. Holley added many improvements to the factory. It worked much better than Bessemer's original plant.

The Pennsylvania Railroad was very interested in using this new steel for railroad tracks. They helped fund Holley's second mill. Between 1866 and 1877, 11 Bessemer steel mills were licensed in the US.

Andrew Carnegie was one of the investors. He saw how important this new steel technology was. In 1872, he visited Bessemer. Holley built a new steel mill for Carnegie. It was called the Edgar Thomson Steel Works. It opened in 1875. This started the United States' growth as a major steel producer.

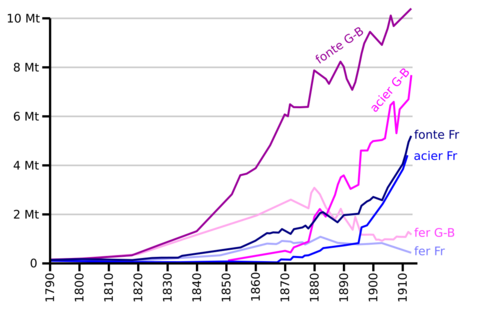

Using the Bessemer process, Carnegie Steel made railroad rails much cheaper. The price dropped from $100 per ton in 1873 to $50 per ton by 1875. By the 1890s, Carnegie was selling rails for $18 per ton. Before Carnegie's mill opened, the US made about 157,000 tons of steel per year. By 1910, American companies made 26 million tons of steel each year.

Bessemer steel was mainly used for railroad rails in the US. For the Brooklyn Bridge, there was a debate about using cheaper Bessemer steel or more expensive crucible steel. In the end, a different company got the contract for the bridge.

How it Works

Using the Bessemer process, it took only 10 to 20 minutes to turn three to five tons of iron into steel. Before this, it could take a whole day of heating and stirring.

Cleaning the Iron

When air is blown through the melted pig iron, it adds oxygen. This oxygen burns away impurities like silicon, manganese, and carbon. These impurities turn into gases or a solid waste called slag.

The inside lining of the converter is also important. If the raw iron has little phosphorus, clay linings can be used. This is called the acid Bessemer process. If the iron has a lot of phosphorus, special linings made of dolomite or magnesite are needed. This is the basic Bessemer process. After the impurities are removed, other materials like spiegeleisen can be added. This helps make the steel have the right properties.

Controlling the Process

Once the steel was ready, it was poured into large ladles. Then it was moved into molds. The lighter slag was left behind. The whole process, called the "blow," took about 20 minutes. Workers watched the flame coming out of the converter's mouth. The flame's color and shape told them how the cleaning was going. Today, machines help by using light to check the flame. After the blow, more carbon and other materials were added to get the exact type of steel needed.

A Bessemer converter could handle a batch of 5 to 30 tons of hot metal at a time. Factories often used two converters. One would be making steel while the other was being filled or emptied.

Older Ways to Make Steel

By the early 1800s, the puddling process was common. But it couldn't remove all impurities. The Bessemer process was different because it didn't need extra fuel to heat the iron. The impurities in the iron itself created the heat. This made steel production much cheaper. But it meant finding raw materials with the right qualities was important.

High-quality steel was made by adding carbon to pure wrought iron. This was often imported from Sweden. This method, called the cementation process, involved heating iron bars with charcoal for up to a week. This made "blister steel." This steel was then melted in small pots to make crucible steel. This process used a lot of expensive coke fuel.

The Bessemer process cut the time needed to make steel to about half an hour. It only needed coke to melt the pig iron at the start. The first Bessemer converters made steel for about £7 a ton. This was much cheaper than the £50 to £60 a ton for older methods.

"Basic" vs. Acidic Bessemer Process

Sidney Gilchrist Thomas was a chemist who wanted to solve the problem of phosphorus in iron. Phosphorus made steel weak. He believed he found a solution. He contacted his cousin, Percy Gilchrist, who was also a chemist.

Thomas's idea was to use linings made of dolomite or limestone inside the Bessemer converter. The original Bessemer process used clay linings. This new method became known as the 'basic' Bessemer process. The original was called the 'acid' Bessemer process. An extra benefit of the basic process was that it created more slag. This slag could be used as a valuable phosphate fertilizer.

Why It Was Important

In 1898, Scientific American magazine wrote about how Bessemer steel changed the world. They said that cheap steel helped railroads grow into new areas. This led to more settlements and made trading goods much easier and cheaper.

The Bessemer process changed how steel was made. It lowered the cost of steel from £40 per ton to just £6–7 per ton. It also made it possible to produce steel much faster and in larger amounts. This important material became widely available. The process also needed fewer workers.

Before Bessemer, steel was too expensive for big structures like bridges or building frames. Wrought iron was used instead. After the Bessemer process, steel and wrought iron cost about the same. Many users, especially railroads, switched to steel. However, Bessemer steel had some quality problems. For example, the nitrogen in the air blast could make it brittle. So, it wasn't used for all building parts. Open-hearth steel was better for those uses.

Steel greatly improved railroads. Steel rails lasted ten times longer than iron rails. Steel rails were also heavier, so they could support heavier trains. This meant trains could carry more goods.

Why It Was Replaced

By 1895 in the UK, people noticed that the Bessemer process was losing its popularity. The open hearth method was becoming more common. Some thought this was because of a lack of skilled workers and new technology.

The basic Bessemer process (Thomas-Gilchrist process) was used longer, especially in Europe. This was because European iron ores often had high phosphorus content. The open-hearth process couldn't remove all the phosphorus as well. In Germany, most cheap construction steel in the 1950s and 1960s was made this way.

In the US, commercial Bessemer steel production stopped in 1968. It was replaced by newer methods like the basic oxygen process. These new processes allowed for better control over the steel's final makeup. The Bessemer process was very fast (10–20 minutes per batch). This meant there wasn't much time to check the steel's chemistry. Bessemer converters also didn't remove phosphorus well. As low-phosphorus ores became more expensive, the cost of the Bessemer process went up. It also couldn't use much scrap steel.

The basic oxygen steelmaking process is like an improved Bessemer process. It blows pure oxygen into the molten iron instead of air. Henry Bessemer knew that pure oxygen would be better. But in the 1800s, technology wasn't advanced enough to make large amounts of pure oxygen cheaply.

See also

- Cementation (metallurgy) process

- Methods of crucible steel production

| Percy Lavon Julian |

| Katherine Johnson |

| George Washington Carver |

| Annie Easley |