Basic oxygen steelmaking facts for kids

Basic oxygen steelmaking (often called BOS) is a modern way to make steel. It takes molten pig iron, which has a lot of carbon, and turns it into low-carbon steel. This happens by blowing pure oxygen through the hot liquid iron. The oxygen helps to burn off the carbon and other unwanted stuff. This process is called "basic" because special chemicals called fluxes (like calcium oxide) are added. These chemicals are bases and help clean the metal and protect the inside of the furnace.

This method was first thought of in 1948 by a Swiss engineer named Robert Durrer. It became widely used in 1952–1953 by two Austrian steel companies. The special furnace used is called an LD converter, named after the Austrian towns Linz and Donawitz. It's an improved version of the older Bessemer converter. The LD process made steelmaking much faster and cheaper. It also meant fewer workers were needed. By the year 2000, basic oxygen furnaces made 60% of all the steel in the world. Modern furnaces can turn up to 400 tons of iron into steel in less than 40 minutes! This is much quicker than older methods that took 10 to 12 hours.

Contents

How Basic Oxygen Steelmaking Started

The basic oxygen process was developed by Robert Durrer, a Swiss engineer. It was then put into use by two smaller steel companies in Austria after World War II.

Back in 1856, Henry Bessemer had an idea to make steel using oxygen. But for almost 100 years, it was too expensive to get enough pure oxygen. So, steelmakers used air instead. During World War II, engineers in Germany, Belgium, and Switzerland worked on using oxygen. Only Durrer and Heinrich Heilbrugge managed to make it work on a large scale.

In 1943, Durrer returned to Switzerland. In 1947, he bought a small experimental converter from the US. On April 3, 1948, this new converter made its first steel. This new process was good because it could use a lot of scrap metal along with new iron. In 1948, Durrer's company and two Austrian companies, VÖEST and ÖAMG, decided to use this new process.

By June 1949, VÖEST created their own version of Durrer's process, called the LD (Linz-Donawitz) process. In 1949, VÖEST and ÖAMG decided to build their first large oxygen converters. These started working in November 1952 (Linz) and May 1953 (Donawitz). They became leaders in steelmaking and many people visited to see how it worked. The LD process made steel faster and cheaper for Austria.

In the first LD process, oxygen was blown from the top onto the molten iron. In the 1960s, steelmakers started blowing oxygen from the bottom. They also used inert gas to stir the metal and remove impurities like phosphorus.

In the Soviet Union, some experiments with this process happened in 1934. But they didn't have good technology to make liquid oxygen. In 1939, a Russian physicist named Pyotr Kapitsa improved a machine called a centrifugal turboexpander. This machine helped make liquid oxygen easily. Since then, most machines that make liquid oxygen for steelmaking use Kapitsa's design.

Big American steel companies were slow to use this new technology. The first oxygen converters in the US started in late 1954. By 1970, half of the world's steel and 80% of Japan's steel was made using oxygen converters. Later in the 20th century, another method using electric arc furnaces and scrap steel became more common. But the basic oxygen process still makes about 60% of the world's steel.

How the Process Works

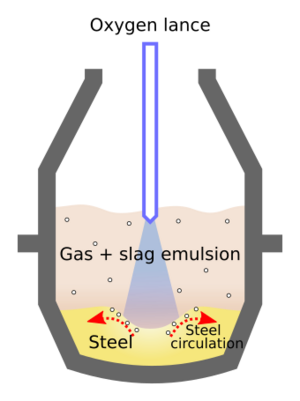

Basic oxygen steelmaking is the main way to turn molten pig iron into steel. This is done by blowing oxygen through a special pipe (called a lance) into the hot liquid iron inside a large container called a converter. This process creates a lot of heat because of chemical reactions.

Here are the steps for making steel using the basic oxygen process:

- Molten pig iron (also called "hot metal") from a blast furnace is poured into a big container called a ladle.

- Sometimes, the metal in the ladle is cleaned first. This removes unwanted stuff like sulfur, silicon, and phosphorus. For example, to remove sulfur, powdered magnesium is added. This causes a strong reaction that turns sulfur into magnesium sulfide, which is then removed.

- Next, the furnace is filled. This is called charging. The BOS process makes its own heat, so it's important to have the right mix of hot liquid iron and cold scrap metal (about 25–30%). The BOS container can tilt to make it easier to add the scrap and hot metal.

- The container is then set upright. A water-cooled lance with special nozzles is lowered close to the surface of the hot metal. Very pure oxygen is blown in at a very high speed. This oxygen "blows" over the hot metal, making the carbon in the steel burn. This forms carbon monoxide and carbon dioxide, and the temperature quickly rises to about 1700°C (3090°F). This intense heat melts the scrap metal, lowers the carbon in the iron, and helps remove other unwanted chemical elements. Using pure oxygen (instead of air, like in the old Bessemer process) is better because air contains nitrogen, which is not good for the steel.

- Special fluxes (like calcium oxide or dolomite) are added to the container. These form a layer called slag. The slag helps to absorb impurities and protects the inside of the furnace. As the oxygen blows, the metal and fluxes mix, helping the cleaning process. Near the end of this "blowing" part (which takes about 20 minutes), the temperature is checked, and samples are taken.

- The BOS container is then tilted. The finished steel is poured through a special hole into another steel ladle. This is called tapping the steel. The steel can be further improved in this ladle by adding other materials to give it special qualities. Sometimes, argon or nitrogen gas is bubbled through the steel to help the added materials mix well.

- After the steel is poured out, the slag is poured from the BOS container into special pots and then removed.

Different Types of Converters

Older converters had a bottom that could be taken off and fixed. Modern converters have a fixed bottom with special plugs for blowing argon gas. There's also an energy optimization furnace (EOF) which is a type of BOF. It uses the hot gases from the furnace to preheat the scrap metal, saving energy.

The lance used for blowing oxygen has also changed over time. Some lances are designed to prevent slag from sticking. Other lances can burn the CO gas created during the process into CO2, which adds more heat. To make sure only steel is poured out and not slag, special tools like darts or slag detectors are used. Modern converters are now fully automated, meaning computers control the blowing and other steps.

See also

- AJAX furnace, an older type of furnace that used oxygen

| Delilah Pierce |

| Gordon Parks |

| Augusta Savage |

| Charles Ethan Porter |