Carbon steel facts for kids

Carbon steel is a special type of metal called an alloy. Think of it like a mix of two main ingredients: iron and carbon. There might be tiny bits of other elements like manganese, silicon, or copper, but not enough to change how the steel usually behaves.

The amount of carbon in the steel makes a big difference!

- If there's only a little carbon, the steel is soft and easy to shape, much like pure iron.

- But if you add more carbon, the steel becomes much harder and stronger. However, it also becomes less flexible (we call this less ductile) and harder to join together by welding. More carbon also means the steel melts at a lower temperature.

Contents

What are the different types of carbon steel?

Carbon steel comes in different types, depending on how much carbon is mixed in:

- Mild (low carbon) steel: This type has a small amount of carbon, usually from 0.05% to 0.25%. It's not super strong, but it's cheap and easy to bend or shape. You can make its surface harder by a process called carburizing.

- Medium carbon steel: This has more carbon, from about 0.29% to 0.54%. It's a good balance of being strong and still a bit flexible. It's often used for car parts or large metal pieces.

- High carbon steel: With about 0.55% to 0.95% carbon, this steel is very strong. It's used for things like springs or very strong wires.

- Very high carbon steel: This type has the most carbon, from about 0.96% to 2.1%. It's made in a special way to be extra strong for specific uses.

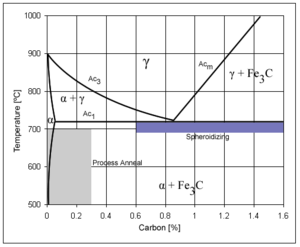

Steel can also be treated with heat. This helps make parts that are easy to shape when soft, and then hardened later to make them stronger and more resistant to wear and impacts. Sometimes, steel is shaped using "cold-working" methods, which means bending or pressing the metal when it's cool.

How is carbon steel made and used?

Mild steel is the most common type of steel you'll find. It's popular because it's not too expensive and works well for many different jobs. It has a low carbon content (up to 0.3%), which means it's not too brittle (doesn't break easily) and not too flexible. When you heat mild steel, it becomes soft enough to be shaped by a blacksmith. It's often used for big structures, like buildings, where lots of steel is needed. This metal is quite heavy, and it's strong enough to handle a lot of force before breaking.

For carbon steels that can be made harder with heat, the carbon content is usually between 0.30% and 1.70%. Even tiny amounts of other elements can change how good the steel is. For example, a little bit of sulfur can make the steel "red-short," meaning it becomes brittle and crumbly when hot. Manganese is often added to make low carbon steels easier to harden.

Hardened steel usually means steel that has been treated with heat, often by quickly cooling it (called quenching) or by quenching and then heating it again (called tempering).

Silver Steel is a very special type of high-carbon steel. It gets its name because it looks shiny and bright. It's a very strong tool steel, usually with about 1% to 1.2% carbon. It can be ground very precisely. It's sometimes used to make things like straight razors because it can hold a super sharp edge.

What are heat treatments for steel?

The main reason to heat treat plain-carbon steel is to change its properties. This can make it more flexible, harder, stronger, or better at resisting impacts. It's like baking a cake – the heat changes the ingredients to get the final texture you want!

See also

In Spanish: Acero al carbono para niños

In Spanish: Acero al carbono para niños