Flux (metallurgy) facts for kids

Imagine you're trying to glue two pieces of metal together, but they have a thin layer of invisible rust or dirt on them. The glue won't stick well, right? That's where flux comes in! In the world of metallurgy (the science of metals), a flux is a special chemical helper. It makes sure metals are clean and ready to be joined or processed.

Fluxes can do several things at once. They can act like a cleaning agent, a flowing agent, or a purifying agent. They are used both when making new metals from their ores (called extractive metallurgy) and when joining metal pieces together (like in metalworking). The name "flux" comes from its ability to make melted metals flow more easily.

Long ago, people used things like sodium carbonate, potash, charcoal, borax, and lime as fluxes. Even iron ore was used to help melt copper! These early fluxes helped stop rust from forming on hot metal and absorbed unwanted bits into a waste material called slag, which could then be removed.

Fluxes are also used in factories where metals like aluminium are melted. They help remove impurities or add tiny amounts of helpful elements, like titanium, to the metal.

When you're joining metals at high temperatures, like in soldering, brazing, or welding, fluxes are super important. They stop the metal from rusting (oxidizing) when it gets hot. Think of it as a protective shield! Flux also helps the melted joining material (like solder) spread out and stick better to the clean metal surface. Without flux, the solder might just form little balls instead of a smooth, strong connection.

Contents

What is Flux?

Flux is a chemical substance that helps metals in different ways, especially when they are heated. Its main jobs are to clean metal surfaces, prevent them from rusting, and help melted metals flow smoothly.

Helping Metals Join

When you want to connect two pieces of metal, especially in electronics or jewelry making, you often use a process that involves melting another metal to act as a "glue." Flux is essential for this.

Soldering with Flux

Soldering is a common way to join metal parts, especially in electronics. Flux helps in three key ways:

- It cleans any rust or dirt (oxidized metal) from the surfaces you want to join.

- It creates a barrier to keep air away, stopping more rust from forming while you're working.

- It helps the liquid solder spread out and stick better to the clean metal.

Some fluxes can be a bit strong or "corrosive," meaning they could damage the metal if left on. So, after soldering, it's often important to clean the parts carefully to remove any leftover flux.

Brazing and Silver Soldering

Brazing is similar to soldering but uses much higher temperatures (above 450 °C). It's sometimes called silver soldering or hard soldering. Because of the high heat, metals can rust very quickly. Brazing fluxes need to be stronger to remove existing rust and create a good protective barrier.

Traditionally, borax was used for brazing. Today, many different fluxes are available, often containing chemicals like fluorides. These chemicals can be strong, so it's important to use them carefully and follow safety rules.

Cleaning Metals in Smelting

Smelting is the process of getting pure metal from its ore using heat. In smelting furnaces, special materials called "fluxes" are added. These fluxes help remove unwanted chemicals, like phosphorus, from the metal. They also make the slag (a liquid mix of ash and impurities) more liquid, so it can be easily separated from the pure metal. This is where the word flux originally came from, meaning "to flow."

For example, in steel furnaces, limestone is a common flux. It helps clean the iron and fuel as they are heated.

Why is Flux Important?

Fluxes are important because they make metalworking processes much more effective and reliable. By cleaning surfaces and preventing rust, they ensure that metal joints are strong and that purified metals are truly clean. Without flux, many common metal joining and refining techniques would be very difficult or impossible to do well.

Types of Flux

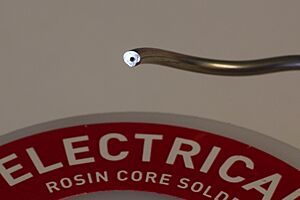

Fluxes come in different types, each designed for specific jobs and metals. They are generally divided into organic and inorganic types, with rosin fluxes being a popular organic type.

Organic Fluxes

Organic fluxes are often used for soft soldering, especially in electronics. They are made from chemicals that usually come from living things or carbon compounds. These fluxes typically have four main parts:

- Activators: These are the chemicals that do the cleaning. They break down and dissolve the rust (metal oxides) on the surface, making the metal ready for joining.

- Vehicles: These are liquids or solids that can handle high temperatures. They act as a protective shield against oxygen and help carry away the dissolved rust.

- Solvents: These help apply the flux easily. They usually evaporate during the heating process.

- Additives: These are extra chemicals that change how the flux works, like making it stickier or flow better.

Inorganic Fluxes

Inorganic fluxes are usually used for brazing and other high-temperature jobs because they can withstand more heat than organic fluxes. They often contain chemicals like borax, borates, fluorides, and chlorides. Some of these, like halides, are very active at lower temperatures but can be quite strong and corrosive.

Rosin Fluxes

Rosin flux is a very common type of organic flux, especially in electronics. Rosin comes from pine trees and is a sticky, glassy solid. At normal temperatures, it's not very reactive, but when it melts (around 120 °C), it becomes slightly acidic. This mild acid can dissolve thin layers of rust from metals like copper.

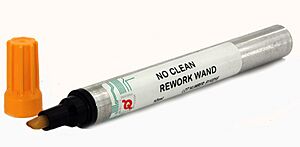

Sometimes, other chemicals called "activators" are added to rosin to make it stronger and work faster, especially for dirtier surfaces. Rosin fluxes are popular because they are effective and their residues are often less corrosive than other types, especially the "no-clean" versions.

Safety First: Using Flux Safely

While fluxes are very helpful, it's important to use them safely because some can be strong chemicals.

- Corrosive Nature: Some fluxes, especially the stronger ones, can be corrosive. This means they can cause damage to metals or even skin if not handled properly. Always wear gloves and goggles when working with flux.

- Fumes: When flux is heated during soldering or brazing, it can release fumes. Breathing in these fumes for a long time can be harmful. Always work in a well-ventilated area, or use a fume extractor to keep the air clean.

- Burns: Molten flux can be very hot and sticky. If it gets on your skin, it can cause serious burns, similar to hot glue. Be extremely careful and always have an adult supervise when working with hot tools and materials.

In some special cases, where even tiny traces of flux could cause problems (like in very precise optical devices), people use "fluxless techniques." These methods use special environments, like a vacuum or protective gases, to prevent rust instead of using flux.

Images for kids

See also

- Flux-cored arc welding

- Gas metal arc welding

- Shielded metal arc welding

| Valerie Thomas |

| Frederick McKinley Jones |

| George Edward Alcorn Jr. |

| Thomas Mensah |