Brazing facts for kids

Brazing is a way to join two or more pieces of metal together. It works by melting a special "filler metal" into the gap between the pieces. Think of it like using a super-strong hot glue made of metal.

A key rule in brazing is that the main metal pieces get very hot, but they do not melt. Only the filler metal melts. The melted filler metal is pulled into the tight space between the pieces by a process called capillary action, similar to how a paper towel soaks up water. When it cools, it creates a strong bond.

Brazing is different from other ways of joining metal:

- Welding melts the main metal pieces to fuse them together. Brazing does not.

- Soldering is like brazing but uses lower temperatures and creates a weaker joint. Soldering is often used for tiny parts in electronics.

Brazing can be used to join different types of metals together, creating a strong and durable connection.

Contents

How Brazing Works

For a strong brazed joint, a few important things are needed. The process is a bit like following a recipe.

A Close Fit

The metal parts must fit together very closely. The gap is usually tiny, often thinner than a piece of paper. This small gap helps the melted filler metal get pulled into the joint through capillary action.

Clean Surfaces

The surfaces of the metal must be extremely clean. Any dirt, oil, or rust (oxide) will stop the filler metal from sticking properly. The metal is often cleaned with chemicals or by scrubbing it before brazing.

The Right Amount of Heat

Heat is needed to melt the filler metal. The temperature must be hot enough to melt the filler, but not hot enough to melt the main metal parts. The heat must also be applied evenly to avoid warping the parts.

Using Flux

To keep the metal clean while it's being heated, a special material called flux is often used. Flux is a paste or powder that covers the joint. It melts and forms a protective layer that stops air from reacting with the hot metal. The flux is pushed out of the way as the filler metal flows in.

Pros and Cons of Brazing

Brazing is a very useful technique, but like any process, it has good and bad points.

Advantages of Brazing

- Joining Different Metals: Brazing is great for joining metals that are not the same, like copper to steel.

- Clean Joints: It produces a very neat and clean joint that usually doesn't need to be ground down or finished afterward.

- Less Heat Damage: Because it uses lower temperatures than welding, there is less risk of bending or warping the metal parts.

- Good for Complex Parts: You can join complicated shapes and multiple parts all at once, which is great for manufacturing.

Disadvantages of Brazing

- Strength: A brazed joint is strong, but usually not as strong as a welded joint.

- High Temperatures: The joint can become weak if it is used in a place that gets very hot, as the filler metal could soften.

- Cleanliness is Key: The process requires the metal to be perfectly clean, which can take extra time and effort.

Common Brazing Methods

There are several ways to heat the parts for brazing. The method chosen depends on the job, the materials, and how many parts need to be made.

Torch Brazing

This is the most common method, especially for smaller jobs. A person uses a gas-powered torch to heat the joint by hand. They then touch the filler metal rod to the hot joint, and it melts and flows into the gap. It requires skill to get the heat just right.

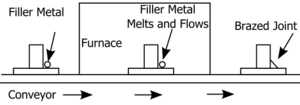

Furnace Brazing

For making many parts at once, furnace brazing is used. The parts, with the filler metal already in place, are put into a large oven called a furnace. The furnace heats everything at the same time to a precise temperature. Often, the furnace is filled with a special gas that prevents the metal from reacting with air, so no flux is needed. This method is great for mass production.

Silver Brazing

Silver brazing is a very common type of brazing that uses a filler metal containing silver. It is sometimes called "hard soldering." This method creates very strong and reliable joints. It is often used in the tool industry to attach super-hard cutting tips (made of a material called cemented carbide) onto steel tools like saw blades.

Braze Welding

Braze welding is a bit different because it doesn't use capillary action to fill a tight gap. Instead, it's used to fill larger gaps, much like welding. A filler rod, usually made of bronze or brass, is melted to join steel parts. It's useful for repairs because it uses less heat than regular welding.

Filler Metals: The "Glue" of Brazing

The filler metal is the key ingredient in brazing. It's the material that melts and flows into the joint to create the bond.

Filler metals are usually alloys, which are mixtures of different metals. They are designed to melt at a lower temperature than the base metals being joined. They come in many forms, like rods, wires, powders, or even pastes.

Some of the most common filler metals are alloys made from:

- Copper and Zinc (brass)

- Copper and Silver

- Aluminum and Silicon

- Gold and Silver

The choice of filler metal depends on the base metals, the strength needed for the joint, and how the joint will be used. For example, a filler metal for joining steel pipes in plumbing would be different from one used for making jewelry.

What Does Flux Do?

Unless brazing is done in a special furnace with a protective atmosphere, a flux is needed. Flux is a chemical substance that plays two very important roles:

- It Cleans the Metal: Flux removes any invisible layers of oxide (rust) from the surface of the base metals.

- It Protects the Metal: When the metal gets hot, flux melts and creates a shield over the joint. This shield stops oxygen in the air from getting to the hot metal and forming more oxides, which would weaken the joint.

After the brazing is done and the part has cooled, any leftover flux must be cleaned off. If left on, it can cause the metal to corrode over time.

Brazing Safely

Brazing involves very high temperatures and can sometimes produce fumes from the metals and flux. Because of this, safety is very important. People who braze must work in an area with good airflow to avoid breathing in any harmful fumes. They also wear protective gear, like special glasses and gloves, to protect themselves from the intense heat and bright light.

| Claudette Colvin |

| Myrlie Evers-Williams |

| Alberta Odell Jones |