Potash facts for kids

Potash is a name for different kinds of salts that have the element potassium in them. These salts can dissolve in water. The name "potash" comes from "pot ash." Long ago, people made it by soaking plant ashes or wood ash in a pot. This was the main way to get potash before the time of modern factories. Even the word "potassium" comes from "potash"!

Today, a lot of potash is made around the world. In 2021, over 71.9 million tonnes were produced. Canada makes the most potash, and most of it is used to make fertilizer. Potash fertilizers are the biggest industrial use for potassium. The element potassium was first separated in 1807 by using electricity on a substance called caustic potash.

Contents

What is Potash?

Potash refers to different compounds and materials that contain potassium. The word "potash" comes from an old Dutch word, "potaschen", which meant "pot ashes" in 1477.

The old way to make potassium carbonate was to collect wood ash. People called "ash burners" would do this. They would then soak the ashes in water, a process called leaching. After that, they would boil the water in large iron pots until only a white powder was left. This powder was called "pot ash." About 10% of the weight of common wood ash could be turned into potash. Later, the name "potash" was also used for natural minerals that contained potassium salts and the products made from them.

Here are some common types of potash:

| Common name | Chemical name (Formula) |

|---|---|

| Potash fertilizer | This can be potassium chloride (KCl), potassium sulfate (K2SO4), or potassium nitrate (KNO3). It doesn't contain potassium oxide (K2O) because plants can't use that form. The amount of potassium is often measured as if it were K2O to compare different fertilizers. |

| Caustic potash | potassium hydroxide (KOH) |

| Carbonate of potash or pearl ash | potassium carbonate (K2CO3) |

| Muriate of potash (MOP) | potassium chloride (KCl) |

| Nitrate of potash or saltpeter | potassium nitrate (KNO3) |

| Sulfate of potash (SOP) | potassium sulfate (K2SO4) |

History of Potash

Where Potash Comes From

Most of the world's potassium was formed long ago when ancient inland oceans dried up. As the water evaporated, the potassium salts turned into crystals, forming beds of potash ore. These are the places where potash is mined today. These natural deposits are a mix of potassium chloride (KCl) and sodium chloride (NaCl), which is common table salt. Over time, these deposits were buried deep underground by thousands of feet of earth.

Early Uses of Potash

Potash, especially potassium carbonate, has been used since the Bronze Age. People used it to bleach fabrics, make glass, create ceramics, and produce soap. Back then, potash was mainly made by soaking the ashes of land plants.

Potash Production Over Time

Early Mining and Wood Ash

Potash mining began in Ethiopia in the 14th century. One of the largest deposits in the world, about 140 to 150 million tons, is in the Dallol area.

Potash made from wood ash was a very important industrial chemical. It was refined from the ashes of broadleaved trees. Most of this potash came from forested areas in Europe, Russia, and North America. Even though new ways to make artificial alkalis were invented in the late 1700s, they weren't cheap enough to use widely until the late 1800s. So, people still relied on wood ashes for potash.

Potash became a big international trade item in Europe starting in the early 1300s. It's thought that Europe needed 6 million cubic meters or more of imported potash each year by the early 1600s. Between 1420 and 1620, the main cities that exported wood-derived potash were Gdańsk, Königsberg, and Riga. In the late 1400s, London was the top importer because it was a center for making soft soap. The Dutch were major suppliers and users in the 1500s. By the 1640s, wars and political problems meant that exports moved from the Baltic Sea to Archangel, Russia. By 1700, Russian ash was the most common, but Gdańsk was still known for its high-quality potash.

Kelp and North America

On the Orkney islands, people started making potash and soda ash from kelp (seaweed) ash around 1719. This continued for about 100 years. Glass and soap makers really wanted these products.

By the 1700s, better quality American potash was being sent to Britain more and more. In the late 1700s and early 1800s, making potash gave settlers in North America much-needed money and credit. They needed to clear wooded land for farming. The easiest way was to burn any wood they didn't need. Ashes from hardwood trees could then be used to make lye. This lye could be used to make soap or boiled down to create valuable potash. Hardwood could produce a lot of ashes per acre. In 1790, selling ashes could earn settlers in rural New York State almost as much money as hiring someone to clear the same land. Potash making became a big industry in British North America, with Great Britain being the most important market. The American potash industry moved across the country as settlers cleared more land.

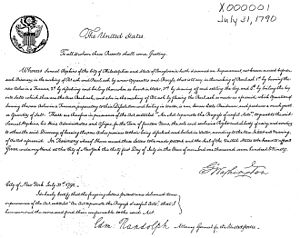

The First U.S. Patent

The very first U.S. patent was given in 1790 to Samuel Hopkins. It was for a better way to make "Pot ash and Pearl ash." Pearl ash was a purer kind of potash made by heating it in a special oven called a reverberatory furnace. In England, "potash pits" were once used to make potash for soap, which was then used to prepare wool for making yarn.

Modern Potash Production

After about 1820, New York became the main source of potash, replacing New England. By 1840, the center was in Ohio. Potash production was always a side business, happening because people needed to clear land for agriculture.

Canada's Role

From 1767, Canada started exporting potash made from wood ashes. By 1811, 70% of Britain's potash imports came from Canada. By 1865, Canada exported over 43,000 barrels of potash and pearl ash. In 1871, there were 519 places called asheries (where ashes were processed) operating.

The wood-ash industry became less important in the late 1800s. This happened when Germany started producing large amounts of potash from mineral salts. In 1943, potash was found in Saskatchewan, Canada, while people were drilling for oil. Serious exploration began in 1951. In 1958, the Potash Company of America became the first to produce potash in Canada from an underground mine. However, water leaked in, and production stopped in 1959. After a lot of repairs, production started again in 1965. The underground mine flooded in 1987, but it was reopened in 1989 as a "solution mine."

In 1964, a Canadian company called Kalium Chemicals opened the first potash mine that used a "solution process." This discovery was also made during oil exploration. The mine was built near Regina, Saskatchewan, and reached depths of over 1500 meters. Today, it is part of the Mosaic Corporation.

In the early 1900s, potash deposits were found in the Dallol Depression in Ethiopia. These areas have huge amounts of potash, and one spot is easy to mine from the surface. It was explored in the 1960s but stopped due to a flood. Attempts to restart mining in the 1990s were stopped by a war and haven't started again.

How Potash is Mined

Deep Mining and Surface Mining

All commercial potash deposits originally came from dried-up ancient seas. They are often buried very deep underground. Potash ores usually have a lot of potassium chloride (KCl), sodium chloride (NaCl), and other salts and clays. They are typically dug out using traditional deep shaft mining, where the ore is brought up and then ground into a powder. Most potash mines today are very deep, some going down as much as 4,400 feet (1,400 m). Other mines are strip mines, where the potash layers are closer to the surface. In processing plants above ground, the potassium chloride is separated from the other materials to make a high-quality potassium fertilizer. Other potassium salts, like potassium sulfate, can also be separated.

Dissolving and Evaporating Potash

Other ways to get potash include dissolving it underground or using evaporation from salty water. In the evaporation method, hot water is pumped into the potash deposit. The potash dissolves, and the salty water is then pumped to the surface. There, the water is left to evaporate, often using sunlight, which makes the potash more concentrated. Special chemicals called amines are then added. The amines stick to the potassium chloride (KCl) but not to the sodium chloride (NaCl). Air bubbles are then added, which stick to the amine-coated KCl and make it float to the surface. The NaCl and clay sink to the bottom. The floating KCl is then skimmed off, dried, and packaged as a potassium-rich fertilizer. KCl dissolves easily in water, so plants can quickly use it as a nutrient.

Scientists in India have also looked into getting potassium salts from seawater. When salt is taken out of seawater by evaporation, potassium salts become concentrated in the leftover liquid called "bittern."

Potash Production Around the World

Potash deposits are found all over the world. As of 2015, potash was being mined in Canada, Russia, China, Belarus, Israel, Germany, Chile, the United States, Jordan, Spain, the United Kingdom, Uzbekistan, and Brazil. The biggest deposits are very deep under the Prairie Evaporite Formation in Saskatchewan, Canada.

The Permian Basin in the United States has major mines outside Carlsbad, New Mexico. It also has the world's purest potash deposit in Lea County, New Mexico, which is about 80% pure. Canada is the largest producer, followed by Russia and Belarus. Most of Canada's potash is in Saskatchewan and is mined by companies like The Mosaic Company, Nutrien, and K+S.

In China, most potash deposits are in the deserts and salt flats of its western provinces, especially Qinghai. Geologists found these deposits in the 1950s, but they weren't used much until China's economic reforms in the 1980s. In 1989, the Qinghai Potash Fertilizer Factory opened, which greatly increased China's production of potassium chloride.

In 2013, almost 70% of potash production was controlled by two big groups: Canpotex (a Canadian exporting firm) and the Belarusian Potash Company. However, one of the companies in the Belarusian group, Uralkali, ended their partnership in July 2013.

Here's a list of countries and how much potash they produced in recent years (measured in K2O equivalent):

| Rank | Country | Production in metric tons K2O equivalent | ||||

|---|---|---|---|---|---|---|

| 2016 | 2017 | 2018 | 2019 | 2020 | ||

| 1 | 10,789,662 | 12,562,695 | 14,023,931 | 12,643,318 | 13,881,665 | |

| 2 | 6,480,000 | 7,300,000 | 7,055,000 | 7,368,000 | 8,167,300 | |

| 3 | 6,180,100 | 7,101,800 | 7,346,096 | 7,348,293 | 7,562,153 | |

| 4 | 5,783,000 | 5,534,000 | 5,452,000 | 5,902,000 | 5,530,000 | |

| 5 | 2,750,841 | 2,963,561 | 2,754,085 | 2,615,284 | 2,874,026 | |

| 6 | 2,093,100 | 2,126,700 | 2,149,300 | 2,043,500 | 2,415,600 | |

| 7 | 1,222,140 | 1,415,260 | 1,485,960 | 1,516,460 | 1,598,200 | |

| 8 | 1,303,840 | 1,238,630 | 991,180 | 683,540 | 966,680 | |

| 9 | 510,000 | 480,000 | 520,000 | 510,000 | 460,000 | |

| 10 | 672,246 | 557,468 | 635,490 | 547,100 | 455,000 | |

| 11 | 198,600 | 307,600 | 343,500 | 286,900 | 442,500 | |

| 12 | 316,429 | 306,296 | 201,181 | 269,300 | 276,600 | |

| 13 | 83,000 | 114,900 | 176,900 | 198,400 | 210,000 | |

| 14 | 482,800 | 297,400 | 291,100 | 84,000 | 99,260 | |

| 15 | 10,500 | 15,300 | 32,900 | 37,200 | 37,000 | |

| 16 | 0 | 0 | 15,200 | 11,100 | 16,000 | |

| 17 | 0 | 0 | 1,700 | 17,800 | 4,400 | |

| Total | 38,876,258 | 42,321,610 | 43,475,523 | 42,082,195 | 44,996,384 | |

Safety for Potash Miners

Throughout history, potash miners have faced health risks. Breathing in things like radon and asbestos can cause serious lung diseases. Miners can also get a lung disease called silicosis. A study from 1977 to 1987 found that potash workers generally had low rates of heart disease, but there was a small difference for workers who stayed above ground.

How Potash is Used

| Country | Production | Reserves |

|---|---|---|

| Canada | 14.2 (28.57%) | 1,100 (33.33%) |

| Russia | 9.1 (17.14%) | 400 (12.12%) |

| Belarus | 7.6 (16.48%) | 750 (22.73%) |

| China | 6.0 (14.76%) | 170 (5.15%) |

| Germany | 2.8 (6.90%) | 150 (4.55%) |

| Israel | 2.4 (5.14%) | Large (?%) |

| Jordan | 1.6 (3.37%) | Large (?%) |

| Chile | 0.9 (1.85%) | 100 (3.03%) |

| United States | 0.5 (1.04%) | 220 (6.67%) |

| Spain | 0.4 (0.79%) | 68 (2.06%) |

| Brazil | 0.3 (0.58%) | 2.3 (0.01%) |

| Other countries | 0.4 (0.76%) | 300 (9.09%) |

| World total | 46.3 (100.00%) | >3,300 (100.00%) |

Potash as Fertilizer

Potassium is one of the three most important nutrients for plants and crops, along with nitrogen and phosphorus. People have used it as a soil fertilizer since ancient times. About 90% of all potash produced today is used for this purpose. Pure potassium doesn't exist in nature because it reacts strongly with water. However, as part of different compounds, potassium makes up about 2.6% of the Earth's crust. It's the seventh most common element.

Potash is important for farming because it helps plants hold water, grow more crops, and improves their nutrient value, taste, color, and texture. It also helps plants resist diseases. It's used a lot for fruits, vegetables, rice, wheat, other grains, sugar, corn, soybeans, palm oil, and cotton. All these crops benefit from the quality-improving properties of potash.

The need for food and animal feed has been increasing since 2000. This is because the world's population grows by about 75 million people each year. Economic growth in Asia and Latin America has greatly increased the use of potash-based fertilizer. As people in developing countries earn more money, they add more meat and dairy products to their diets. This means more land needs to be farmed, more fertilizer needs to be used, and more animals need to be fed, all of which require more potash.

After many years of increasing, fertilizer use slowed down in 2008. The main reason was a worldwide economic downturn, which led to lower prices and more unsold fertilizer.

The biggest users of potash in the world are China, the United States, Brazil, and India. Brazil imports 90% of the potash it needs. It's expected that potash use for fertilizers will increase to about 37.8 million tonnes by 2022.

When people talk about potash imports and exports, they often measure it in "K2O equivalent." This is just a way to compare amounts, even though fertilizer never actually contains potassium oxide itself. Potassium oxide is a harsh chemical that absorbs water easily.

Potash Prices

At the start of 2008, potash prices went up very quickly, from less than US$200 per tonne to a high of US$875 in February 2009. After that, prices dropped a lot, reaching US$310 in April 2010. They recovered in 2011–2012 but fell again in 2013. For example, prices in November 2011 were about US$470 per tonne, but by May 2013, they were stable at US$393. When the world's largest potash group broke up in July 2013, potash prices were expected to drop by about 20 percent. By the end of 2015, potash was trading at US$295 per tonne. In April 2016, it was US$269. In May 2017, prices had settled around US$216 per tonne, which was 18% lower than the year before. By January 2018, prices started to recover to about US$225 per tonne. The demand for potash around the world doesn't change much, even when prices go up or down.

Other Uses for Potash

Besides being used as a fertilizer, potassium chloride is important in many industries. It's used in aluminium recycling, and in the chloralkali industry to make potassium hydroxide. It's also used in metal electroplating, in liquids for oil-well drilling fluid, for melting snow and ice, and for treating steel with heat. In medicine, it's used to treat low potassium levels. It also helps with water softening.

Potassium hydroxide is used for treating industrial water. It's also used to make potassium carbonate, different types of potassium phosphate, many other potassium chemicals, and soap. Potassium carbonate is used to make animal feed supplements, cement, fire extinguishers, food products, photographic chemicals, and textiles. It's also used in brewing beer, making medicines, and as a catalyst (something that speeds up a chemical reaction) for making synthetic rubber. When combined with silica sand, it makes potassium silicate, also known as waterglass, which is used in paints and for arc welding electrodes. These uses, not related to fertilizer, make up about 15% of the potash used each year in the United States.

What Can Be Used Instead of Potash?

There is no substitute for potassium as a necessary nutrient for plants, animals, and humans. Manure and glauconite (a green sand) are sources that contain small amounts of potassium. However, they can only be moved short distances to farms because they are not very concentrated.

Related pages

See also

In Spanish: Potasa (mineral) para niños

In Spanish: Potasa (mineral) para niños

- Bone ash

- Saltpeter

- Saltwater soap

- Sodium hydroxide

| Delilah Pierce |

| Gordon Parks |

| Augusta Savage |

| Charles Ethan Porter |