Converter (metallurgy) facts for kids

Imagine a giant machine that can change one metal into another! A converter is a special machine, like a big oven, that turns raw iron into strong steel.

Raw iron, often called pig iron, comes from a blast furnace. It has a lot of carbon in it, up to 4%. This makes the iron too hard and easy to break for most uses. To make it useful, the carbon must be burned away. This process is called conversion, and the machine that does it is a converter.

Contents

The First Steel Converter

The very first successful converter was invented by Sir Henry Bessemer in 1856. He built a large, pear-shaped container. It had special openings at the bottom called "tuyeres" to blow air in.

How the Bessemer Converter Worked

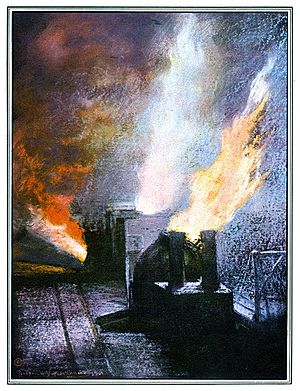

Hot, melted pig iron from a blast furnace was poured into the Bessemer converter. Then, air was pumped in from the bottom with high pressure. This caused a loud noise and a huge flame, sometimes 20 meters tall, to shoot out of the converter's mouth! After about ten minutes, all the pig iron had become steel.

The Steel Age Begins

The Bessemer converter was a huge step forward. It was the first machine that could reliably turn pig iron into steel. Because of this invention, steel became very common and much cheaper to make. This started the "Age of Steel," changing how buildings, bridges, and machines were made.

Modern Steel Converters

While the Bessemer converter was amazing, steel can be even better if only oxygen is used instead of air. Air contains nitrogen, which can be bad for some types of steel. A modern converter, called a basic oxygen furnace, uses pure oxygen. It was invented in 1949 in Austria.

How a Basic Oxygen Furnace Works

A modern basic oxygen converter looks like a large, pumpkin-shaped vessel. It is made from steel and lined with special heat-resistant materials. These materials, like calcium oxide, help the vessel handle the very high temperatures of the melted metal.

First, melted pig iron and scrap metal are put into the converter. The scrap metal is often rusty, meaning it has oxygen on it. This rust reacts with the pig iron, burning away some carbon and creating heat. This heat helps melt the scrap metal.

The Oxygen Blast

Once all the scrap has melted, a special pipe called an "oxygen lance" is lowered into the pig iron. A very fast and strong blast of pure oxygen is then shot in. This oxygen quickly burns away all the carbon. It also mixes the liquid steel very well.

After the carbon is gone, a little more carbon might be added to reach the perfect level for the type of steel needed. The result is liquid steel, which is then poured out. This liquid steel is then sent to a rolling mill to be shaped into different steel products.

Images for kids

See also

In Spanish: Convertidor metalúrgico para niños

In Spanish: Convertidor metalúrgico para niños

| Georgia Louise Harris Brown |

| Julian Abele |

| Norma Merrick Sklarek |

| William Sidney Pittman |