Boring (manufacturing) facts for kids

Boring is a super important process in machining, which is all about shaping metal. Imagine you have a hole that's already been made, maybe by a drill or from a casting. Boring is like making that hole bigger and super precise. It uses a special tool with a single sharp point, kind of like a tiny knife, to carefully shave away material from the inside of the hole.

Think of it like this: if turning is shaping the outside of a metal part, boring is shaping the inside! It's used to make holes exactly the right size and shape, even tapered (slanted) holes. For example, it's used to make the inside of a gun barrel or an engine cylinder perfectly smooth and accurate.

There are different ways to bore a hole. Sometimes the tool is held on both sides of the hole, which is called lineboring. Other times, it's only held on one side, which works for holes that don't go all the way through (called blind holes). Backboring is a cool trick where the tool goes through an existing hole and then bores from the "back" side of the metal piece.

Boring can be a bit tricky because the tool is mostly inside the hole, making it harder to support and see what's happening. But it's a very important skill in machining! The first boring machine tool was invented by John Wilkinson way back in 1775.

Contents

What Machines Use Boring?

You can do boring on many different machine tools. Some are general-purpose machines, like lathes (also called turning centers) or milling machines (also called machining centers). These machines can do many different jobs, including boring.

Then there are special machines made just for boring. These are called jig borers or boring machines (also known as boring mills). There are two main types:

- Vertical boring mills: Here, the metal piece spins around like a record on a turntable, and the boring tool moves up and down or side to side. It's a bit like a vertical lathe.

- Horizontal boring mills: With these, the metal piece sits still on a table, and the boring tool spins around a horizontal (flat) axis. It's like a special horizontal milling machine.

Boring Mills and Milling Machines

Boring mills and milling machines can cut both vertically and horizontally inside a hole. The cutting tool usually has a single point and is made from strong materials like high-speed steel or carbide. You can even make a tapered (slanted) hole by moving the cutting tool in two directions at once.

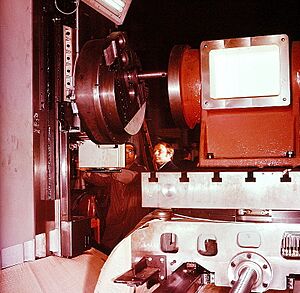

Boring machines come in all sizes. Small metal pieces can be bored on a lathe. But for really big parts, you need a boring mill. Some boring mills can handle pieces as large as 20 m (66 ft) (about 65 feet) across! They need a lot of power to do this.

To keep the tools cool, especially when making deep holes, coolant often flows through a hollow part of the boring bar. Special disks inside the bar help stop vibrations, which keeps the cut smooth. Many modern boring machines use computers to control them, making the process very accurate and consistent.

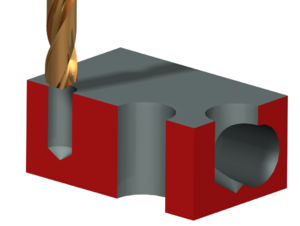

When designing parts for boring, it's usually better to have holes that go all the way through the metal piece (called "through holes") rather than holes that stop partway (called "blind holes"). Also, a smooth, continuous surface inside the hole is easier to bore than one with breaks or gaps. The part of the machine that holds the cutting tool, called the boring bar, needs to be very strong and stiff.

Making very deep holes, especially narrow ones, is a big challenge. But special tools and methods have been developed for it. For example, "gun drilling" and "cannon boring" were first used to make barrels for firearms. These techniques use multiple cutting points and special ways to pump cutting fluid to the cutting edges, helping to make very accurate deep holes.

Lathes and Boring

Lathes are very common machines that can also perform boring. When boring on a lathe, the metal piece usually spins while held in a device called a chuck. A boring bar with a cutting tip is then fed into an existing hole in the spinning piece. As the tool cuts, it shaves off tiny pieces of metal, called chips, and creates a smooth, accurate hole.

You can make different shapes of holes on a lathe, including straight holes and tapered holes. For straight holes, the tool moves parallel to the spinning metal piece. For tapered holes, it moves at an angle. You can even add different diameters within the same hole, creating steps or counterbores.

There are different ways to hold the metal piece on a lathe:

- Three-jaw chuck: Great for holding round or hexagonal pieces because it automatically centers them.

- Four-jaw chuck: Used for holding oddly shaped pieces or for getting super-accurate centering on round pieces, but it takes more time to set up.

- Collet: Offers very good accuracy and centers the piece well, but can be more expensive.

- Faceplate: Also used for holding irregular shapes.

How Accurate Can Boring Be?

Boring can make holes very accurate. For most jobs, it's easy to keep the hole size within about ±0.25 mm (or ±0.010 in). Even for deep holes, it's usually not too hard to get within ±0.13 mm (or ±0.005 in).

Getting even more accurate, like within ±0.025 mm (or ±0.001 in), becomes more challenging, especially for deep holes. It's not just about the exact diameter, but also about the hole being perfectly round and straight all the way through. For the most precise jobs, where holes need to be extremely accurate, other processes like grinding, honing, or lapping might be used after boring.

The smoothness of the inside of the hole, called its surface finish, can vary. It's usually quite smooth, but for super smooth surfaces, other finishing methods might be needed.

Over the years, boring technology has gotten much better. New types of carbide and ceramic cutting tools allow for more accuracy and smoother surfaces without needing extra grinding. They can also work with harder metals. However, even with the best tools, making parts perfect down to a few micrometres (tiny fractions of a hair's width) is hard. Metal can slightly change shape due to tiny forces or temperature changes, which can affect the final accuracy. Engineers are always looking for new materials and designs to overcome these challenges!

See also

- Drilling

- Laser drilling

- Horizontal boring machine

- Jig borer

- Single-pass bore finishing

Images for kids

| William Lucy |

| Charles Hayes |

| Cleveland Robinson |