John Wilkinson (industrialist) facts for kids

Quick facts for kids

John Wilkinson

|

|

|---|---|

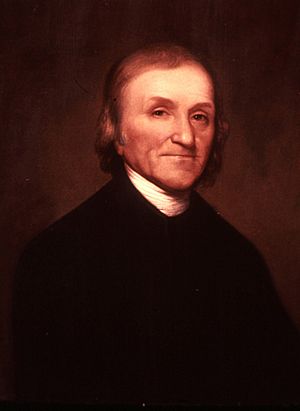

Wilkinson by Lemuel Francis Abbott

|

|

| Born | 1728 Little Clifton, Cumberland, England

|

| Died | 14 July 1808 (aged 79–80) Bradley, Staffordshire, England

|

| Resting place | Lindale Church, Lindale-in-Cartmel, England |

| Nationality | British |

| Occupation | Ironmaster, Entrepreneur, builder of first iron boat, partner in world's first iron bridge |

John "Iron-Mad" Wilkinson (1728 – 14 July 1808) was an English industrialist who was super important during the Industrial Revolution. He was a leader in making and using cast iron products. He invented a special machine that could drill very accurate holes in cast iron cylinders. These cylinders were used for things like cannon barrels and parts for James Watt's steam engines. People even called his drilling machine the first ever machine tool.

Wilkinson also created a powerful fan for blast furnaces. This fan made the furnaces much hotter and more efficient. He also helped fund the building of the very first iron bridge in Coalbrookdale. He was famous for his way of drilling cannons, his skills in casting iron, and his work with the French government to set up a cannon factory.

Contents

John Wilkinson's Life Story

Early Years and Family Background

John Wilkinson was born in 1728 in Little Clifton, Cumberland, England. This area is now part of Cumbria. He was the oldest son of Isaac Wilkinson and Mary Johnson. At the time, his father, Isaac, worked at a blast furnace there. This furnace was one of the first to use coke instead of charcoal, a new idea started by Abraham Darby.

John and his half-brother William grew up in a non-conformist family. This meant they were Protestants who didn't follow the main Church of England. John went to a special school called a dissenting academy in Kendal. His sister Mary married another non-conformist, Joseph Priestley, in 1762. Priestley also helped teach John's younger brother, William.

In 1745, when John was 17, he started training with a merchant in Liverpool. After five years, he became a business partner with his father. In 1753, his father moved to Bersham Ironworks in north Wales. John stayed in Kirkby Lonsdale and married Ann Maudesley in 1755.

Becoming an Iron Master

After working with his father, John Wilkinson became a partner in the Bersham business in 1755. In 1757, with other partners, he built a new blast furnace at Willey in Shropshire. Later, he built another furnace and works at New Willey. He lived in Broseley in a house called 'The Lawns'. This house became his main office for many years. He also had other houses nearby for managing his business.

In east Shropshire, he also started iron works in places like Snedshill and Hollinswood. He and Edward Blakeway also rented land to build another large works at Bradley near Wolverhampton. He became known as the 'Father' of the big iron industry in South Staffordshire. In 1761, he also took over the Bersham Ironworks. Bradley became his biggest and most successful project. He did many experiments there, trying to use raw coal instead of coke to make cast iron. At its busiest, Bradley had many blast furnaces, a brick factory, potteries, glass factories, and rolling mills. The Birmingham Canal was later built close to the Bradley works.

Wilkinson's Amazing Inventions

Wilkinson was a very creative inventor. He came up with many new products and ways of doing things, especially with cast iron and wrought iron. His invention of a machine tool for drilling cast iron cannons was a huge step forward. It allowed for the accurate drilling of cylinders for the first Watt steam engines. He also made the air supply better for blast furnaces with a new bellows design. He was also the first to use wrought iron in canal barges. He strongly supported building the first important cast iron bridge at Coalbrookdale.

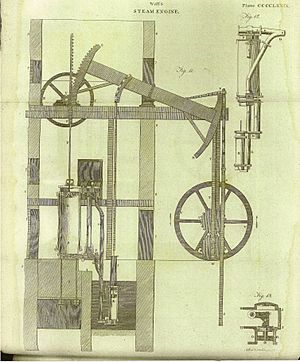

Cannon Drilling Machine

Bersham became famous for making high-quality iron castings, including guns and cannon. Before Wilkinson, cannons were cast with a hole in the middle, then drilled to fix any problems. But in 1774, Wilkinson patented a new way to drill iron guns from a solid piece of metal. His method involved spinning the gun barrel instead of the drilling tool. This made the guns much more accurate because the hole was perfectly even. It also made them less likely to explode. Even though the patent was later cancelled, Wilkinson remained a top gun maker.

In 1792, Wilkinson bought the Brymbo Hall estate in Denbighshire, near Bersham. He built furnaces and other factories there. After he died, the ironworks were quiet for some years. But in 1842, they became important again and eventually turned into Brymbo Steelworks, which operated until 1990.

Drilling Machine for Steam Engines

For several years, James Watt had trouble getting perfectly drilled cylinders for his steam engines. He had to use hammered iron, which wasn't perfectly round. This caused steam to leak past the piston. In 1774, John Wilkinson invented a drilling machine that fixed this problem. In his machine, the shaft holding the cutting tool went all the way through the cylinder and was supported at both ends. Older machines only supported the tool from one side.

With his new machine, Wilkinson could drill the cylinder for Boulton & Watt's first successful engine. Because his cylinders were so precise, he got an exclusive contract to supply them. This greatly improved the efficiency of steam engines. Before this, drilling technology was mainly used for gun barrels. Wilkinson's invention was a big step forward, expanding drilling into engines, pumps, and other industrial uses.

Wilkinson was very interested in getting orders for these more efficient steam engines. He also wanted to find more uses for cast iron. He bought shares in eight Cornish copper mines to help provide money for them. He saw that steam engines could power machines in ironworks, like fans for furnaces, hammers, and rolling mills. The first rotary engine (an engine that turns a wheel) was installed at Bradley in 1783. Among his many inventions was a special rolling mill with two steam cylinders that made the process much cheaper.

Hydraulic Blowing Engine

In 1757, Wilkinson patented a blowing engine that used water power. This machine increased the air blast going into the tuyeres (air holes) of blast furnaces. This made it possible to produce cast iron faster. The historian Joseph Needham said Wilkinson's design was similar to one described in 1313 by a Chinese government expert named Wang Zhen.

The Famous Iron Bridge

In 1775, John Wilkinson was the main person who pushed for building the Iron Bridge. This bridge would connect the important industrial town of Broseley with the other side of the River Severn. His friend Thomas Farnolls Pritchard had sent him plans for the bridge. A group of people, mostly Broseley business owners, formed a committee. They agreed to use iron instead of wood or stone and worked to get prices and permission from Parliament.

Wilkinson's strong belief and effort kept the group together through several problems in Parliament. If Wilkinson hadn't succeeded, the bridge might not have been built, or it might have been made of other materials. Because of him, the area is now called 'Ironbridge' and is a World Heritage Site. Abraham Darby III was chosen to build the bridge. Wilkinson sold his shares to Abraham Darby III in 1777. This left Darby to finish the project, which opened successfully in 1781.

In 1787, Wilkinson launched the first barge made of wrought iron. It was built in Broseley. This was a big step that would become common for boats and even large ships in the future. He also patented several other inventions.

Copper Business Interests

John Wilkinson made a lot of money selling high-quality iron goods. He then started investing in many copper businesses. In 1761, the Royal Navy covered the bottom of a ship called HMS Alarm with copper sheets. This was to stop sea creatures from growing on the hull and to protect it from tiny worms that damaged wood. These problems slowed ships down and caused serious damage, especially in warm waters. After this worked well, the Navy decided all ships should be covered in copper. This created a huge demand for copper, which Wilkinson noticed when he visited shipyards.

He bought shares in eight copper mines in Cornwall. He also met Thomas Williams, known as the 'Copper King' from the Parys Mountain mines in Anglesey. Wilkinson supplied Williams with lots of iron plates and equipment. He also provided scrap iron to help get copper out of solutions. Wilkinson bought a small share in the Mona Mine at Parys Mountain. He also bought shares in Williams's businesses in places like Holywell, Flintshire, St Helens, and Swansea.

Wilkinson and Williams worked together on many projects. They were among the first to make their own special coins, called trade tokens, to help with the shortage of small change. Together, they started the Cornish Metal Company in 1785. This company helped sell copper. Its goal was to make sure Cornish miners got a good price and that copper users had a stable price. They set up warehouses in Birmingham, London, Bristol, and Liverpool.

To help his businesses and to handle his trade tokens, Wilkinson also became a partner in banks in Birmingham, Bilston, Bradley, Brymbo, and Shrewsbury.

Lead Mines and Factories

Wilkinson bought lead mines in Minera (near Wrexham), Llyn Pandy, and Mold in Flintshire. He installed steam pumping engines to make these mines profitable again. His lead was sent out through the port of Chester. To use some of the lead he produced, Wilkinson had a lead pipe factory in Rotherhithe, London. This factory operated for many years. It eventually made the solder used in car factories.

Helping Others and Community Work

Wilkinson was known as a good employer. Wherever he started new factories, he built small houses for his workers and their families. He gave a lot of money to support his brother-in-law, the famous chemist Dr. Joseph Priestley. He became a church warden in Broseley. Later, he was chosen as High Sheriff of Denbighshire. In schools that didn't have slates for writing, he provided iron troughs filled with sand for children to practice writing and math. He even provided a cast-iron pulpit for the church in Bilston.

Later Life and Legacy

John Wilkinson married Ann Maudsley in 1759. Her family was wealthy, and her money helped him buy a share in the New Willey Company. After Ann died, he married Mary Lee when he was 35. Her money helped him buy out his business partners. Later in his life, he had children, a boy and two girls.

By 1796, when he was 68, he was making about one-eighth of all the cast iron in Britain. He became very rich and a bit unusual. His "iron madness" was strongest in the 1790s. He wanted almost everything around him to be made of iron. He even had several coffins made of iron and a huge iron obelisk to mark his grave. This obelisk still stands in the village of Lindale-in-Cartmel, in Cumbria. He was appointed Sheriff of Denbighshire in 1799.

He passed away on July 14, 1808, at his factory in Bradley. He likely died from diabetes. He was first buried at his Castlehead estate. He left a very large amount of money in his will. He wanted his three children to be the main heirs. However, his nephew, Thomas Jones, challenged the will in court. By 1828, most of his wealth was gone due to lawsuits and poor management. His body, in its special iron coffin, was moved several times over the years, but its exact location is now unknown.

|

| Anna J. Cooper |

| Mary McLeod Bethune |

| Lillie Mae Bradford |