Drilling facts for kids

Drilling is a way of making holes in solid materials. Imagine a spinning tool, called a drill bit, that cuts a perfectly round hole. This drill bit usually has sharp edges and spins very fast, from hundreds to thousands of times a minute. As it spins, it presses against the material, cutting off tiny pieces called chips or swarf. These chips are then removed from the hole.

When drilling into rock, the process is a bit different. Instead of just spinning, the drill bit often hammers into the rock with quick, repeated movements. The hammering can happen from outside the hole (a "top-hammer drill") or inside the hole (a "down-the-hole drill"). Drills used for horizontal holes are called drifter drills.

Sometimes, special drill bits can even cut holes that are not round, like a square shape!

Contents

How Drilling Works

When you drill a hole, it usually has a sharp edge where the drill enters. On the other side, where the drill exits, there might be rough edges called burrs. The inside of the hole often has spiral marks from the drill bit.

Drilling can slightly change the material around the hole. It might create tiny stresses or a thin layer of changed material on the new surface. This can sometimes make the material more likely to rust or crack. To prevent this, a special finishing step can be done.

For drill bits with spiral grooves (called flutes), the chips are carried out of the hole through these grooves. Depending on the material, the chips can be long spirals or small flakes. Long chips often mean the material is easy to drill.

It's best to drill holes straight into the surface, at a 90-degree angle. This helps stop the drill bit from "walking" or moving away from where you want the hole to be. The longer and thinner the drill bit, the more it might "walk." Here are some ways to stop this:

- Making a starting mark: You can make a small dent or mark before drilling. This can be done by:

* Adding a mark when the material is first made (like casting or forging). * Using a center punch to make a small dent. * Using a spot drill (also called a center drill) to make a shallow guide hole.

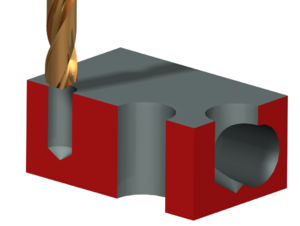

- Using a drill jig: This is a special tool that holds the drill bit firmly in place with drill bushings, guiding it accurately.

The smoothness of a drilled hole can vary a lot, from very smooth to quite rough. Finishing cuts make smoother holes, while rough cuts make rougher ones.

Often, a special liquid called cutting fluid is used. This liquid helps cool the drill bit, makes it last longer, allows faster drilling, creates a smoother hole, and helps remove chips. It's usually applied by pouring it over the material or spraying a mist.

There are many types of drills, each for a different job. For example, a subland drill can make holes of more than one size. A spade drill is good for making larger holes. An indexable drill helps manage the chips that are cut.

Spot Drilling

Spot drilling means drilling a shallow hole that acts as a guide for the main drill bit. It's only drilled partway into the material, just enough to help the next drill bit start in the right spot.

Centre Drilling

A centre drill is a tool with two cutting edges and a 60-degree cone shape. It's used to make small, cone-shaped guide holes in a material. These holes help hold the material in place for other machining processes like turning or grinding.

Deep Hole Drilling

Deep hole drilling means making a hole that is more than ten times deeper than it is wide. This requires special tools to make sure the hole stays straight and accurate. It's also important to make sure the hole is perfectly round and has a good surface finish.

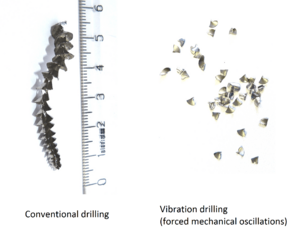

Special methods like gun drilling or BTA drilling are used for deep holes. These methods differ in how they deliver coolant and remove chips. Sometimes, the tool spins one way and the material spins the other way to keep the hole straight. Other methods include trepanning or vibration drilling. Vibration drilling uses small, controlled up-and-down movements of the drill to break chips into tiny pieces, which are then easily removed.

High-tech systems are used to monitor the drilling process, checking things like force, twisting, and vibrations. Too much vibration can cause the drill to break in deep hole drilling. Special coolants are also often used.

Gun Drilling

Gun drilling was first developed to make gun barrels. It's great for drilling very deep, small-diameter holes. The hole can be more than 300 times deeper than it is wide! A key feature of gun drills is that they stay centered on their own. They spin like regular drills, but they have special pads that slide along the hole's surface, keeping the drill bit perfectly in the middle. Gun drilling is usually done at high speeds but with slow forward movement.

Trepanning

Trepanning is used for making larger holes (up to about 915 mm or 36 inches wide) when a regular drill bit isn't practical or cost-effective. Trepanning works by cutting out a solid disk, much like using a drafting compass. It's used on flat materials like sheet metal, granite (for curling stones!), or large structural parts. Trepanning can also make grooves for things like O-rings.

Microdrilling

Microdrilling is about making very tiny holes, less than 0.5 mm (about 0.02 inches) wide. Drilling such small holes is tricky because you can't use drills that feed coolant through them, and the drill spindle needs to spin extremely fast, often over 10,000 revolutions per minute.

Vibration Drilling

Vibration drilling started in the 1950s. The main idea is to make the drill bit vibrate up and down slightly while it's moving forward. This breaks the chips into small pieces, which are then much easier to remove from the hole.

There are two main types of vibration drilling: self-maintained systems and forced vibration systems. Many are still being researched. Some systems use the tool's natural vibration to make it vibrate while cutting. Others use special electronic systems (piezoelectric) to create and control tiny, fast vibrations. Mechanical systems can also create vibrations, usually with a few oscillations per rotation and a slightly larger movement.

One mechanical system, like MITIS's SineHoling® technology, is used in industries. Vibration drilling is great for deep holes, drilling through layers of different materials (like in airplanes), and drilling without lubrication. It generally makes drilling more reliable and easier to control.

Circle Interpolating

Circle interpolating, also known as orbital drilling, is a way to make holes using special machine cutters.

In orbital drilling, the cutting tool spins around its own center, but it also moves in a circle around the center of the hole you want to make. The tool can then move up and down to drill the hole, or sideways to make an opening or cavity.

By changing how far the tool's path is from the hole's center, you can use one size of cutting tool to make holes of different sizes. This means you don't need as many different tools!

The name "orbital drilling" comes from the tool "orbiting" around the hole's center. This special movement has many benefits over regular drilling, making holes much more accurate. It also creates less pushing force, which means less burr (rough edges) when drilling in metals. When drilling in composite materials, it helps prevent the layers from separating (delamination).

Drilling Different Materials

Drilling in Metal

When drilling metal, the spiral grooves (flutes) on the drill bit carry the chips away from the tip. The cutting edges keep making more chips, pushing them out of the hole. If the hole is too deep, or if the drill isn't pulled back often enough, the chips can get stuck. Cutting fluid helps prevent this by cooling and lubricating the drill tip and helping chips flow out. Sometimes, coolant is even pumped through tiny holes inside the drill bit itself, especially with gun drills.

When drilling aluminum, cutting fluid helps make a smooth, accurate hole and stops the metal from sticking to the drill bit. For soft metals like brass, which can cause the drill to "chatter" (vibrate and tear the metal), the cutting edge can be ground to a slightly wider angle (91 to 93 degrees). This makes the drill push the metal away instead of grabbing it, preventing chatter. However, this can create more friction and very hot chips.

For heavy drilling and deep holes, special "oil-hole drills" are used. These drills have a small hole through which lubricant is pumped to the drill tip, flowing out along the flutes. While you can use a regular drill press, these are often seen in automatic machines where the material spins instead of the drill bit.

In computer-controlled (CNC) machines, a method called peck drilling or interrupted cut drilling is used for deep holes (about three times deeper than the drill's width). This involves drilling partway into the material, then pulling the drill back to the surface to clear chips. This is repeated until the hole is finished. A faster version, high speed peck drilling or chip breaking, only pulls the drill back slightly. This is quicker but only for moderately deep holes, as it can overheat the drill. It's also used to break long, stringy chips.

When you can't bring the material to a large CNC machine, a Magnetic Base Drilling Machine can be used. Its magnetic base lets you drill in horizontal positions or even on a ceiling. These machines often use special cutters that drill much faster with less speed. These cutters come in various sizes and depths. They are widely used in construction, shipbuilding, and the oil and gas industries. In oil and gas, pneumatic (air-powered) magnetic drills are used to avoid sparks. Special tube magnetic drills can even attach to pipes. Heavy-duty plate drilling machines are used for making high-quality holes in steel structures, bridges, and shipyards.

Drilling in Wood

Wood is softer than most metals, so drilling in wood is much easier and faster. You don't need cutting fluids. The main things to watch out for are making clean entry and exit holes and preventing the wood from burning. To avoid burning, use sharp drill bits and the right drilling speed. Regular twist drill bits, used for metal, also work in wood but can tear out wood around the hole's edges. This isn't a problem for rough carpentry, and there are fast-cutting bits for wood like spade bits and self-feeding auger bits.

For cleaner holes in fine woodworking, special drill bits like brad-point bits, Forstner bits, and hole saws have been developed. To prevent chipping when the drill exits, you can place a scrap piece of wood behind the workpiece. The same trick can keep the hole entry neat.

Starting holes in wood is easier because you can press the drill bit into the wood to make a small dent, which helps the bit stay exactly where you want it.

Other Materials

Some materials, like plastics, other non-metals, and even some metals, can heat up a lot when drilled. This heat can make them expand, causing the drilled hole to be smaller than you wanted.

Related Processes

Here are some other processes that are similar to drilling or often done with it:

- Counterboring: This makes a stepped hole where a wider hole follows a narrower one partway into the material.

- Countersinking: Similar to counterboring, but the wider part of the hole is cone-shaped.

- Boring: This precisely enlarges an existing hole using a single cutting point.

- Friction drilling: This method makes holes by pushing a special tool into the material at high speed, heating it up and shaping it without cutting chips.

- Reaming: This process makes an existing hole slightly larger and gives it very smooth sides.

- Spot facing: This is like milling; it creates a flat, smooth surface on a specific area of a rough workpiece.

See also

In Spanish: Perforación para niños

In Spanish: Perforación para niños

- Laser drilling

- Drilling rig

| Delilah Pierce |

| Gordon Parks |

| Augusta Savage |

| Charles Ethan Porter |