Contactor facts for kids

A contactor is an electrical switch. It is used to turn on or off a powerful electrical circuit. Think of it like a remote control for electricity. A small electrical signal tells the contactor to switch on or off a much larger electrical flow.

Contactors come in many shapes and sizes. They can handle different amounts of electricity. Some are small enough to fit in your hand, while others are as big as a small car! They can switch currents from a few amps (like what powers a light bulb) up to thousands of amps (like what powers a whole factory).

Unlike a circuit breaker, a contactor is not made to stop a sudden, dangerous short circuit. Instead, it's designed for regular turning on and off of power. Contactors are used to control things like electric motors, lights in big buildings, heating systems, and other large electrical devices.

Contents

How Contactors Are Built

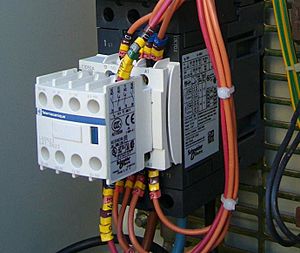

Contactors are built to handle strong electrical currents safely. They have parts that help them switch power without damage.

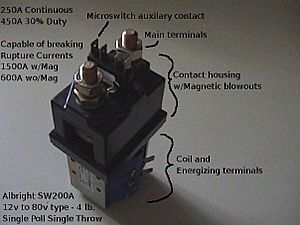

Magnetic Blowouts

Sometimes, special magnets called magnetic blowouts are added to contactors. When a contactor switches off a strong current, it can create a spark, called an arc. These magnets help to stretch out and cool down this arc very quickly. This makes the contactor safer and lets it switch even more power. For example, the contactor in the picture can switch more than twice as much current with these magnets!

Economizer Circuits

To save energy, some contactors have an economizer circuit. When a contactor first turns on, it needs a bit more power to pull its parts together. Once it's closed, it needs less power to stay closed. An economizer circuit helps reduce the power needed to keep the contactor on. This saves electricity and keeps the contactor from getting too hot. These circuits are common in contactors that use DC power or very large AC contactors.

Latching Contactors

For large lighting systems, like those in office buildings, special latching contactors are used. These contactors have two coils. One coil briefly turns the power on, and the other briefly turns it off. This means the contactor doesn't need constant power to stay in either the "on" or "off" position, saving even more energy.

Basic Parts

A basic contactor has a coil that gets an electrical signal (either AC or DC) to activate it. It also has at least two "poles," which are the main switches that control the high-power circuit.

How Contactors Work

A contactor is a type of relay. Relays are also electrical switches, but contactors are designed for much higher power. Relays usually handle smaller currents and can be set up to be normally open (off) or normally closed (on). Contactors, however, are usually designed to be normally open and only switch on when activated. If a switch handles more than 15 amps or a few kilowatts of power, it's usually called a contactor.

Inside a contactor, there's an electromagnet. When electricity flows through this electromagnet, it creates a magnetic field. This field pulls a movable metal part (the "core") towards a stationary part. This movement closes the electrical contacts, allowing the main power to flow.

When the electromagnet first turns on, it needs more current to pull the parts together because there's an air gap. Once the parts touch, the electromagnet needs less current to hold them.

For contactors that use AC power, a small part of the electromagnet's core has a "shading coil." This coil helps to smooth out the magnetic pull, preventing the contactor from buzzing loudly as the AC power changes direction.

Most contactors for lower voltages (under 600 volts) are "air break" contactors. This means they use ordinary air to help put out the spark (arc) when the circuit is opened. For very high voltages, modern contactors often use a vacuum inside to prevent sparks, making them "vacuum contactors."

Contactors used for controlling motors can be part of a larger system called a "combination starter." This system might include fuses or circuit breakers for protection, and other devices to prevent the motor from being overloaded. In big factories, many contactors are often grouped together in special cabinets called motor control centers.

Related pages

See also

In Spanish: Contactor para niños

In Spanish: Contactor para niños