Cotton gin facts for kids

A cotton gin is a special machine. Its name means "cotton engine." This machine quickly separates cotton fibers from their seeds. Before the cotton gin, people had to do this by hand. It took a very long time. The cotton gin made this job much faster and easier.

The seeds removed by the gin can be used in two ways. Farmers can plant them to grow more cotton. Or, they can be used to make cottonseed oil.

Simple roller gins were used in places like India a very long time ago, even before the year 500. An improved roller gin with a special "worm-gear" was invented around the 1500s. This design was so good that it is still used in some places today.

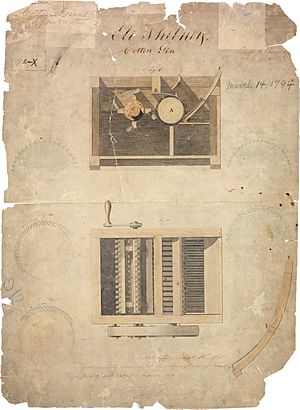

An American inventor named Eli Whitney created a new kind of mechanical cotton gin in 1793. He received a patent for it in 1794. Whitney's machine used wire screens and small hooks to pull cotton fibers through. Brushes then cleaned the loose cotton to stop the machine from getting stuck.

This invention changed cotton farming in the United States. It made growing cotton much more profitable. This led to a greater need for workers on farms in the Southern United States. The cotton gin played a role in the economic and social changes that eventually contributed to the American Civil War. Today, modern cotton gins are automatic. They use many powerful cleaning parts and saws. They can clean much more cotton than the older hand-powered machines.

Contents

Why We Need Cotton Gins

Cotton grows in fluffy balls called "bolls" on the cotton plant. Inside these bolls, the soft cotton fibers are tightly mixed with seeds. Before we can use the cotton to make clothes or other items, these seeds must be removed.

For a long time, people had to separate the cotton fibers from the seeds by hand. This job took many hours for just a small amount of cotton. It was very slow and hard work. Many simple tools were invented to help, but they were often small and needed a lot of attention to work.

How a Cotton Gin Works

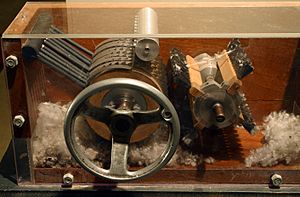

Eli Whitney's cotton gin had two spinning cylinders. The first cylinder had rows of teeth all around it. A metal plate with small holes, called "ginning ribs," was placed close to this cylinder. The teeth could fit through these holes, but just barely.

As the machine turned, the teeth grabbed the cotton fibers. They pulled the fibers through the small holes. The cotton seeds were too big to pass through the holes. So, the metal plate stopped the seeds, separating them from the cotton. The seeds then fell into a container.

On the other side of the first cylinder, a second spinning cylinder had brushes. These brushes gently removed the cleaned cotton from the first cylinder. The clean cotton then dropped into another collection area.

The separated seeds are very useful. They can be planted to grow new cotton plants. Or, they can be sent to a special factory called an oil mill. There, they are made into cottonseed oil and cottonseed meal. After cleaning, the cotton fibers are pressed into large blocks called bales. These bales are then ready for storage and shipping to textile factories.

The Story of Cotton Gins

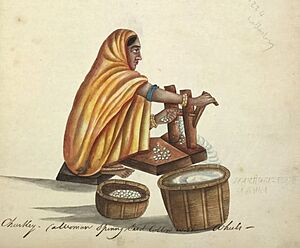

Cotton gins have a long history. The very first ones were used in India as early as the 400s. These early gins had a single roller made of wood or iron and a flat stone or wood piece.

Early Designs and Improvements

Paintings from the 400s in the Ajanta Caves in western India show these early single-roller gins. They were simple tools. They needed a lot of skill to use. A narrow roller was important to remove seeds without crushing them.

Over time, these gins got better. Around the 1100s to 1300s, gins with two rollers appeared in India and China. By the 1500s, the Indian two-roller gin was common in the Mediterranean region. Some of these machines even used waterpower to run.

A very important improvement was the "worm gear" roller gin. This was invented in India between the 1200s and 1300s. It became widely used in the Mughal Empire around the 1500s. This type of gin is still used in some parts of India today.

Another helpful addition was the crank handle. This made the gins easier to operate. These improvements helped India produce much more cotton fabric during the Mughal era.

These early Indian gins were quite efficient for their time. Reports say that one person could clean about 28 pounds (13 kg) of cotton in a day. With some improvements and animal power, these machines could do the work of many more people.

Cotton Gins in America

Indian roller cotton gins were brought to the United States in the mid-1700s. They were used in the southern parts of the country. These gins worked well for a type of cotton with long fibers. However, they were not good for the "short-staple" cotton, which was more common in states like Georgia.

Several people tried to improve these roller gins. But their changes still only worked for long-fiber cotton. This was true until Eli Whitney developed his new gin for short-staple cotton in 1793.

Eli Whitney's Invention

Eli Whitney (1765–1825) applied for a patent for his cotton gin in October 1793. He received the patent in March 1794. Whitney's gin could clean about 50 pounds (23 kg) of cotton each day.

His machine had a wooden cylinder with rows of thin wires. These wires caught the cotton fibers. The wires then pulled the fibers through a comb-like grid. The spaces in the grid were too small for the seeds or other debris to pass through. This separated the seeds from the cotton. Brushes on a second cylinder then cleaned the fibers off the wires, stopping the machine from jamming.

There is some discussion about whether Eli Whitney came up with every part of his gin by himself. Some stories say that Catharine Littlefield Greene suggested using a brush to help separate the cotton. However, this idea has not been fully proven.

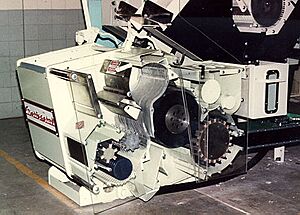

Later Improvements: McCarthy's Gin

Whitney's gin was great for short-staple cotton. But it could damage the fibers of very long-staple cotton. In 1840, Fones McCarthy invented a "Smooth Cylinder Cotton-gin." This was a roller gin that worked well for both short and extra-long staple cotton. It was especially good for the long-fiber types.

McCarthy's gin cleaned cotton much faster than older gins. One horse could power it to produce 150 to 200 pounds (68 to 91 kg) of clean cotton a day. This gin used a moving knife to remove seeds. Later, rotating blades replaced these moving knives. Today, these improved roller gins are still used for extra-long staple cotton in the United States.

The Munger System

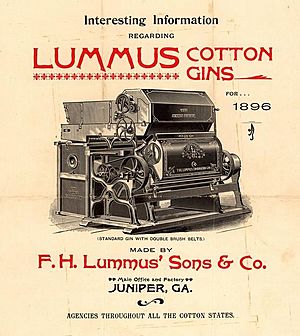

After the American Civil War ended in 1865, cotton gins saw many new features. These included using steam power instead of animals. Automatic feeders made sure the gin ran smoothly. Condensers made the cleaned cotton easier to handle. Indoor presses meant cotton did not have to be carried outside to be baled.

In 1879, Robert S. Munger invented new "system ginning" techniques. He created a system that connected all the ginning machines. This made sure cotton flowed smoothly from one machine to the next. Munger's system used air to move cotton between machines. His inventions made working conditions better and also saved money. They produced cotton faster and with higher quality.

By the 1960s, many more advances were made. But the way cotton moved through the gin machinery was still based on Munger's system. Historians call Munger's work "The Munger Revolution" in cotton ginning.

Big Changes in the United States

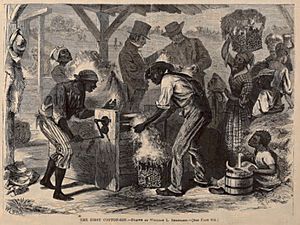

Before the mechanical cotton gin, cleaning cotton took a lot of effort. Eli Whitney's gin made cotton a very profitable business. It helped many people in the Antebellum South become wealthy. Cities like New Orleans, Louisiana and Charleston, South Carolina became important shipping ports. They gained a lot of money from cotton grown in the South.

The huge supply of cotton also created a strong demand for machines to make textiles. This led to many new machine tools being invented in the early 1800s.

The cotton gin caused a massive increase in cotton production in the United States. Most of this growth happened in the South. Cotton production grew from 750,000 bales in 1830 to 2.85 million bales in 1850. As a result, the region became even more focused on large farms that relied on many workers.

While one person might take ten hours to clean one pound (0.45 kg) of cotton by hand, a small team of workers using a cotton gin could produce about fifty pounds (23 kg) in a single day. The number of workers needed on these farms increased greatly. This reversed an economic slowdown that had happened in the late 1700s. The cotton gin helped turn the American South into a major agricultural power.

The invention of the cotton gin led to an increased demand for workers on Southern farms. Because of this unintended impact on the labor system, which shaped the South's economy, the cotton gin is often seen as one of the indirect causes of the American Civil War.

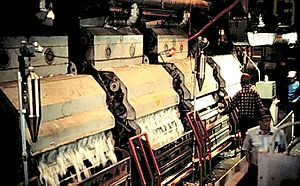

Modern Cotton Gins Today

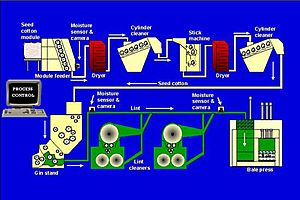

Today, cotton arrives at large industrial gins in big trailers or in compressed blocks called "modules." These modules can weigh up to 10 metric tons (22,000 lb). Some newer cotton pickers even make round modules wrapped in plastic, like hay bales.

Cotton from trailers is sucked into the gin through a large pipe. If cotton comes in modules, a special feeder breaks them apart. It also removes the biggest pieces of foreign material. Then, this loose cotton is sucked into the same starting point as the trailer cotton.

The cotton then goes into a dryer to remove extra moisture. A cylinder cleaner uses spinning, spiked cylinders to break up large clumps of cotton. Smaller bits of dirt and leaves fall through screens. A "stick machine" uses spinning saws to remove larger items like sticks and burrs.

The main gin stand uses saw teeth to pull cotton through "ginning ribs." These ribs pull the fibers away from the seeds, which are too big to pass through. The cleaned seeds are then moved away by a special conveyor system. These seeds are either planted again or sent to an oil mill to make cottonseed oil and cottonseed meal.

After this, "lint cleaners" use more saws and bars to remove any tiny seeds or remaining foreign material. Finally, a bale press squeezes the clean cotton into tight bales. These bales are then ready for storage and shipping. Modern gins can process up to 15 metric tons (33,000 lb) of cotton every hour!

Modern cotton gins produce a lot of leftover material. This includes sticks, leaves, dirt, and small seeds. Scientists are studying how to use this waste to make things like ethanol.

See also

In Spanish: Desmotadora para niños

In Spanish: Desmotadora para niños

- Prattville Gin Factory

- Cotton bale