Dynamometer facts for kids

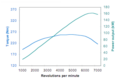

A dynamometer, or "dyno" for short, is a cool device. It measures two things at the same time: how much twisting force (called torque) an engine or motor makes, and how fast it spins (called RPM). With these two numbers, the dyno can figure out the engine's power, usually shown in kW or bhp.

Dynos are used for many things, not just measuring power. For example, they help test how much pollution a car engine makes. They can also help engineers make engines better. This includes fine-tuning how the engine works or studying how different parts wear out.

In medicine, small hand-held dynos measure how strong a person's grip is. Doctors use them to check hand strength. This helps when someone has hurt their hand or has a problem with their nerves.

In physical therapy, dynos measure strength in the back, arms, or legs. Athletes, patients, and workers use them to check their physical fitness. They help understand how much force is needed for different tasks.

Contents

How Do Dynos Work?

An absorbing dynamometer works like a brake. It creates a load that the engine or motor has to push against. This dyno needs to work at any speed. It also needs to handle any amount of twisting force (torque) the test needs.

Some dynos are called "inertia" dynos. They measure power by seeing how much force is needed to speed up a known weight. They don't put a changing load on the engine.

An absorbing dyno usually has ways to measure the twisting force and the speed. The part that absorbs power turns the engine's energy into heat. This heat usually goes into the air or into cooling water. Some special dynos can even turn the absorbed power back into electricity.

Absorbing dynos can have different control systems for different tests.

Testing with Constant Force

This type of dyno has a "braking" system. It applies a set amount of braking force (torque). The engine then speeds up through its range. The dyno calculates power using speed, torque, and a special number.

Testing with Constant Speed

Here, the dyno keeps the engine at a specific speed. It does this by changing how much braking force it applies. This braking force can be controlled by a person or a computer. Many systems use special brakes that can change load quickly.

The power is found by multiplying the engine's angular speed by the twisting force it makes.

A motoring dynamometer works like a motor. It drives the equipment being tested. It can drive the equipment at any speed. It can also create any amount of twisting force needed for the test. Often, electric motors are used for this.

Power is usually not measured directly by dynos. Instead, it's calculated from torque and speed.

- Power (P) = Torque (τ) × Angular Speed (ω)

- Or, Power (P) = Force (F) × Linear Speed (v)

These formulas help dynos show you the power in units like watts or horsepower.

Parts of a Dynamometer

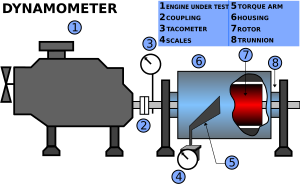

A dyno has a part that absorbs power. It also has ways to measure twisting force (torque) and speed. The power-absorbing part has a spinning rotor inside a case. The rotor connects to the engine being tested.

The dyno creates a braking force between the rotor and its case. This braking force can come from friction, water, magnets, or electricity.

One way to measure torque is to let the dyno's case move a little. It's held back by a special arm connected to a scale. The scale measures the force. The torque is that force multiplied by the length of the arm. Modern dynos often use a "load cell" instead of a scale. This load cell sends an electrical signal that shows the torque.

Another way is to use a special sensor between the engine and the dyno. This sensor directly measures the torque.

When torque and speed signals are available, test results can go straight to a computer. This means no more writing down numbers by hand!

Different Kinds of Dynamometers

Dynos can be grouped in different ways.

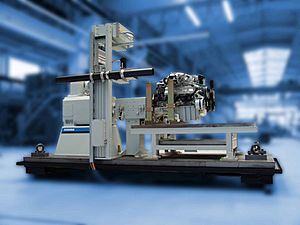

An engine dyno connects directly to an engine. It measures the power right from the engine's spinning shaft.

A chassis dyno measures power from a vehicle's wheels. It does this without taking the engine out of the car. It's like a "rolling road" for the car.

Dynos can also be grouped by the type of braking unit they use.

Types of Braking Units

- Eddy current: These are common in modern car dynos. They use magnets and a spinning metal disc to create resistance. They can change the load very quickly. Most are cooled by air, but some need water.

- Electric motor/generator: These dynos can both absorb power and drive the engine. They use electric motors that can also act as generators. They are more complex but very versatile. They can even send power back to the electricity grid!

- Water brake: These are common and can handle a lot of power. They are smaller and lighter than some other types. They work by using water to create resistance. The water also helps cool them down. A downside is that they can take a while to get a steady load.

Eddy Current Dynos Explained

Eddy current (EC) dynos are very popular for car testing. They can change the load fast. This helps get quick and stable test results.

EC dynos need a metal part that conducts electricity, like a disc. This disc moves through a magnetic field. This movement creates resistance, which acts as a brake. Most EC brakes use cast iron discs, like car brake rotors. They use electromagnets to control the braking force. A computer usually controls these magnets.

Electric Motor/Generator Dynos Explained

These dynos are very special. They can act as a brake to absorb power from an engine. But they can also act as a motor to drive the engine. This is useful for testing things like engine friction. They can even send power back to the electrical grid. This can save energy!

These dynos are usually more expensive and complex.

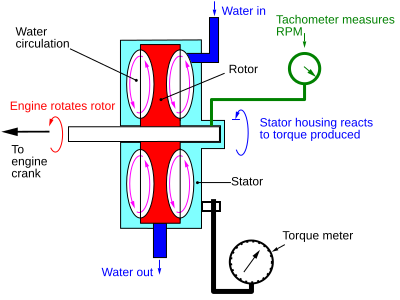

Water Brake Dynos Explained

Water brake dynos are quite common. They were invented a long time ago, in 1877. They are known for handling a lot of power. They are also relatively small and light.

They work by adding water to a special housing. The engine tries to spin the housing, but the water creates resistance. This resistance acts as a brake. The housing is held back by a scale that measures the twisting force. Water constantly flows in and out to carry away the heat.

How Dynos Help Test Engines

Dynos are super important for making modern engines better. They help engineers measure power at different points in a vehicle. This lets them improve the engine or the parts that transfer power. For example, if an engine makes 400 units of torque, but only 350 units reach the wheels, the dyno helps find out why. Dynos are expensive, so they are mostly used by experts.

Types of Dyno Systems

A brake dynamometer puts a changing load on the engine. It measures how well the engine can move or hold its speed against this "braking force." A computer records the braking force and calculates engine power.

An inertia dynamometer uses a fixed weight. It calculates the power needed to speed up that weight. The computer records speed and how fast it speeds up to figure out the torque.

A motoring dynamometer can do what a brake dyno does. Plus, it can also "power" the engine. This is useful for testing very small power outputs. For example, it can copy how an engine works when a car goes downhill.

Types of Dyno Tests

There are three main ways to test with a dyno:

- Steady state: The engine is held at a specific speed for a set time. The dyno's braking unit does this.

- Sweep test: The engine speeds up from a low RPM to a high RPM while under a load. This can be done with inertia or brake dynos.

- Transient test: The engine's power and speed change a lot during the test. These tests are often used for checking vehicle emissions.

More About Sweep Tests

- Inertia sweep: An inertia dyno uses a heavy flywheel. It calculates the power needed to speed up this flywheel.

- Loaded sweep: A brake dyno applies a fixed load to the engine. The engine speeds up on its own.

- Controlled acceleration sweep: This is like a loaded sweep, but the dyno actively controls how fast the engine speeds up.

Modern computer-controlled brake dynos can figure out the engine's total spinning weight. This helps make the test results more accurate.

Engine Dynamometer

An engine dynamometer measures power directly from the engine's main spinning shaft. This means it doesn't count any power lost in the car's gearbox or other parts.

Chassis Dynamometer (Rolling Road)

A chassis dynamometer, also called a rolling road, measures power at the car's drive wheels. The car is usually strapped down onto rollers. The car's wheels turn these rollers, and the dyno measures the power.

Modern chassis dynos use special rollers that help prevent the wheels from slipping. Some dynos even connect directly to the car's wheel hubs. This gives a more direct measurement of torque from the axle.

When testing car emissions, dyno systems often include equipment to collect and analyze exhaust gases. These analyzers are very sensitive and fast.

Because of friction and other losses in a car's parts, the power measured at the wheels is usually 15-20% less than the power measured directly from the engine.

History of Dynamometers

The first dynamometer was invented by George Graham and mentioned by John Desaguliers in 1719. Desaguliers later improved it.

In 1798, a French engineer named Edmé Régnier made his own dyno public.

Gaspard de Prony invented the de Prony brake in 1821, which was another important step.

The company Froude Ltd. says that William Froude invented the hydraulic dynamometer in 1877. The first commercial dynos were made in 1881.

In 1928, a German company built the first vehicle dynos for brake tests. These had a design similar to modern car test stands.

The eddy current dynamometer was invented around 1931 by Martin and Anthony Winther.

Images for kids

See also

In Spanish: Dinamómetro para niños

In Spanish: Dinamómetro para niños

- Dynamometer car (for trains)

- Engine test stand (for engines)

- Force gauge

- Fuel economy in automobiles

- Hand strength dynamometer

- Machine-tool dynamometer

- Universal testing machine

| Ernest Everett Just |

| Mary Jackson |

| Emmett Chappelle |

| Marie Maynard Daly |