Economies of scale facts for kids

Economies of scale happen when a company produces more goods, and the cost of making each item becomes cheaper. Imagine a big factory: it can often make things for less money per item than a small workshop. This is because larger companies can buy materials in bulk, use special machines, or organize their work more efficiently.

This idea has been around for a long time, first talked about by Adam Smith. It's about how making more of something can lower the cost of each piece. The opposite, when costs start to go up as you make more, is called diseconomies of scale.

There are limits to how big a company can get before costs start to rise again. For example, a factory might run out of nearby raw materials, like wood for a paper mill. Or, it might become too expensive to ship products to customers far away. Sometimes, bigger companies can even use energy less efficiently or have more mistakes.

Big companies are usually good at making lots of the same product. But it can be expensive for them to switch to making different kinds of products often. Smaller companies, especially older ones, sometimes stay in business by focusing on special products instead of common ones.

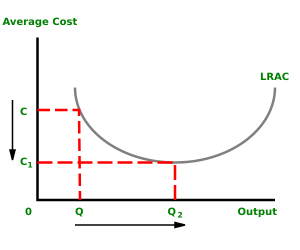

It's important to know that economies of scale are different from just using a factory more. If a factory isn't being used to its full potential, making more products will lower the average cost. But this isn't the same as building a bigger factory to begin with.

Contents

What Are Economies of Scale?

Simply put, economies of scale mean doing things more efficiently as you get bigger. Here are some common ways companies save money when they grow:

- Buying power: They can buy materials in large amounts, often getting a discount.

- Better management: They can hire specialized managers who are experts in certain areas.

- Financial benefits: Banks might offer them lower interest rates on loans.

- Marketing: The cost of advertising can be spread out over many more products.

- Technology: They can use bigger, more efficient machines.

All these things help lower the average cost of making each product over the long run.

Economies of scale can help explain why some companies become very large. They also show why countries benefit from free trade. For example, a small country like Liechtenstein wouldn't efficiently make its own cars just for its local market. But if a carmaker there could sell cars all over the world, it might become profitable.

There are two main types of economies of scale:

- Internal economies of scale: These benefits happen inside a single company as it grows.

- External economies of scale: These benefits happen to an entire industry or area when many companies grow. For example, if many tech companies are in one city, they might all benefit from having more skilled workers available.

Economies of scale exist when it costs less for one big company to make two amounts of a product than for two smaller companies to make those same amounts separately.

How Do Companies Achieve Economies of Scale?

Companies can achieve economies of scale in several ways:

Physical Size and Engineering

Some cost savings come from the physical size of things. Think about a big ship or airplane: it doesn't need twice as many pilots to carry twice the cargo. This is because the surface area (where drag happens) doesn't increase as fast as the volume (where cargo is stored). So, larger vehicles can carry more per gallon of fuel.

The same idea applies to factories, pipes, and ovens. A bigger oven might lose less heat per unit of product than a smaller one. This means energy savings!

Holding Less Stock

Larger companies often need fewer spare parts or extra supplies in proportion to their size. This is because they have more items, so the chance of many breaking down at once is lower. It's like having a big fleet of cars; you don't need a spare tire for every single car.

Better Deals on Purchases

When a company buys a lot of raw materials, it has more power to negotiate lower prices. This is like buying in bulk at a store – you get a better price per item. Also, the paperwork and effort to make a big order are often the same as for a small order, so the cost per item goes down.

Balancing Production Steps

In a factory, different machines might work at different speeds. In a small factory, some machines might sit idle while others catch up. A larger factory can often balance these steps better, keeping all machines busy and making the whole process more efficient. This is especially important for expensive machines.

Specialized Workers and Techniques

As a company grows, it can divide tasks among more workers. This means workers can specialize in one thing and become very good and fast at it. This also allows the company to use more advanced and efficient techniques that might not be practical for a smaller scale.

Smart Management

Many management tasks, like planning and organizing, don't necessarily get harder just because a company is bigger. So, a larger company can spread the cost of its managers over more products. They can also use better accounting and control systems. Good ideas and successful ways of doing things can be used across many different parts of a big company.

Learning and Growing

Companies learn as they make more products. This "learning by doing" helps them find better ways to produce things, which lowers costs over time. This is why the cost of making a new type of product often drops significantly after the first few thousand units are made.

Also, as a company grows, it might find new ways to use its existing resources. For example, a supermarket chain might buy land for a new store, and then the value of the surrounding land they own goes up. They can then sell that extra land for a profit.

Capital and Running Costs

Building bigger factories or buying larger equipment often doesn't cost as much as you might think. For example, a much larger electrical wire or pipe doesn't cost a lot more to install, but it can handle much more. Also, bigger motors or pumps are often more efficient and cost less per unit of power.

Crew Size for Transport

The number of people needed to operate a ship, train, or airplane doesn't increase directly with its size. A bigger plane doesn't need twice as many pilots. This means the cost of the crew is spread over more passengers or cargo, making each trip cheaper per person or item.

Many factories, especially those making chemicals or paper, don't need many more workers even if they double their production. This is because many processes are automated, and the number of workers depends more on how complex the operation is, not how much is being made.

Using Byproducts Wisely

Large factories can find ways to use leftover materials that smaller ones might just throw away. For example, a paper mill can burn wood bark to create energy, or a chemical plant can turn waste products into new, sellable chemicals. This reduces waste and adds to profits.

Economies of Scale and Trade

Larger companies that make more products often earn enough money from selling abroad to cover the costs of exporting. When countries make it easier to trade, companies that are more efficient tend to grow even more. This helps the whole industry become more productive.

Efficient companies are more likely to sell their goods and services to other countries. They can make more money and have lower costs per product. This means big companies often have lower costs per item than small ones. Also, companies that trade often can reduce their overall costs per item compared to those that trade less frequently.

Economies of Scale vs. Returns to Scale

It's easy to mix up "economies of scale" with "returns to scale."

- Economies of scale are about a company's costs. They look at how the cost of making each item changes as the company produces more.

- Returns to scale are about the relationship between what you put in (like workers and materials) and what you get out (the products).

If you double all the things you put into making a product, and you get exactly double the product out, that's "constant returns to scale." If you get less than double, it's "decreasing returns to scale." If you get more than double, it's "increasing returns to scale."

If the prices of materials and labor stay the same no matter how much a company buys, then increasing returns to scale usually mean economies of scale. But if buying more materials makes their prices go up, then even with increasing returns, a company might not see lower costs per item.

In short, returns to scale are about the physical amount of inputs and outputs. Economies of scale are about the costs, which can also be affected by changes in the prices of materials and labor.

External Economies of Scale

External economies of scale are often more common than internal ones. These benefits happen to all companies in an industry, not just one. When new companies join an industry, it can increase competition but also lower the average cost for everyone. This can happen because:

- The whole industry grows bigger.

- Most or all companies in that industry benefit.

- It can lead to fast growth in local areas where these industries are located.

See also

In Spanish: Economía de escala para niños

In Spanish: Economía de escala para niños

- Economies of density

- Economies of scope

- Mass production

- Network effect

| Misty Copeland |

| Raven Wilkinson |

| Debra Austin |

| Aesha Ash |