Fall River Bleachery facts for kids

Quick facts for kids |

|

|

Fall River Bleachery

|

|

|

|

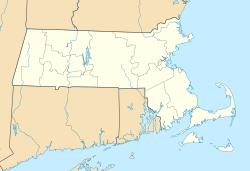

| Location | Fall River, Massachusetts |

|---|---|

| Built | 1872 |

| Architect | Paine, Walter J.; Multiple |

| MPS | Fall River MRA |

| NRHP reference No. | 83000667 |

| Added to NRHP | February 16, 1983 |

The Fall River Bleachery was an important factory in Fall River, Massachusetts. It was a special place where cotton cloth was made super white! This historic building was built in 1872. It was added to the National Register of Historic Places in 1983, which means it's a really important historical site.

Contents

History of the Bleachery

Imagine a time when Fall River was famous for making cloth! Most factories there made 'cotton print cloth.' This cloth was often sent to places like the American Print Works. To print cool designs on cloth, it first needed to be perfectly white. Between 1870 and 1872, Fall River grew super fast. Lots of new cloth factories, called mills, were built.

Why a Bleachery Was Needed

By 1872, a smart chemist named Spencer Borden had an idea. He was the son of Jefferson Borden. Spencer had traveled to Europe to learn how to bleach and dye fabrics. When he came back to the United States, he talked to many factory owners. These owners were from places like New Bedford and Rhode Island. They all agreed that a big bleachery was needed nearby.

Finding the Perfect Spot

A group was formed to find the best location. They tested water from many areas. They checked places in Fall River, Somerset, and Tiverton. They even looked as far north as Bridgewater. They finally picked a spot near Sucker Brook. This brook flowed into South Watuppa Pond in Fall River. Sucker Brook got its water from Stafford Pond. This pond was fed by springs in nearby Tiverton, Rhode Island. The water from Sucker Brook was very pure. It also flowed very quickly, which was perfect for the bleachery.

Building the Factory

The bleachery buildings were made from local Fall River granite. This stone was found right on the building site. The factory was designed so that water from the brook could flow through it easily. This meant they didn't need to use pumps! Jefferson Borden became the first president of the company. The factory could process about thirteen tons of cotton every year.

Growth and Closure

Over the years, the bleachery grew bigger. It needed to keep up with the demand from many nearby factories. By 1906, it could process 50 tons of cloth each day! But in 1938, business became very difficult. The company had to close down. All the machines and equipment were sold at an auction on October 13, 1938. Later, on October 30, 1967, a part of the complex was destroyed by fire. Today, the building is home to Spectrum Lighting, Inc. This company makes lights for buildings.

| Delilah Pierce |

| Gordon Parks |

| Augusta Savage |

| Charles Ethan Porter |