American Printing Company (Fall River Iron Works) facts for kids

The American Printing Company in Fall River, Massachusetts grew to be the largest maker of printed cotton cloth in the United States by the early 1900s. This company began as a part of the Fall River Iron Works, which was started in 1821 by Colonel Richard Borden and Major Bradford Durfee. The American Print Works itself was founded in 1835 by Holder Borden. At its busiest, during World War I, it employed thousands of workers.

Contents

How the Fall River Iron Works Started

The textile industry in Fall River began to grow thanks to new ideas from nearby Rhode Island. This started with Samuel Slater in Pawtucket in 1793. Fall River's first textile mill was built in 1811. More mills followed between 1813 and 1821, built along the "falling" Quequechan River. The city was named after this river.

In 1821, Colonel Richard Borden and Major Bradford Durfee started the Fall River Iron Works. It was located near the lower part of the Quequechan River. Bradford Durfee built ships, and Richard Borden owned a mill for grinding grain. After a tricky start, the Fall River Iron Works became an official company in 1825. It had $200,000 to begin with.

The Iron Works started making nails, metal bars, and other items. These included metal bands for barrels used in the New Bedford whaling industry. They quickly became known for making high-quality nails, and their business did very well.

By 1833, Fall River had 13 cotton mills. These mills employed 1,200 people. They had 31,000 spindles, which is a way to measure how much thread they could spin. They also had 1,050 looms for weaving cloth. The Iron Works played a key role in the early growth of Fall River's textile industry.

By 1840, the Iron Works had about 250 employees. They made over 3.8 million pounds of nails. They also produced 950 tons of iron hoops and 400 tons of metal castings. By 1845, the company was worth $960,000. In 1827, Colonel Borden also started a regular steamship service to Providence, Rhode Island.

Richard Borden always looked for new business opportunities. In 1847, he built the Metacomet Mill. This mill is still standing today on Anawan Street. It is the oldest remaining textile mill in the city. The Iron Works also started the Fall River Gas Company in 1847. This company made gas from coal.

In 1848, the Fall River Iron Works built an office and warehouse by the water in Providence, Rhode Island. They kept this location until 1881. This building is still there and is now used by the Rhode Island School of Design.

By 1876, the Iron Works had two main sites. These included a rolling mill, a nail mill, and a foundry. On average, they produced 7,000 tons of goods each year.

The American Print Works Story

In 1824, Andrew Robeson came from New Bedford. He started the first Print Works in Fall River. This part of the industry would later become very important for the city.

The American Print Works was founded in 1835 by Holder Borden. He was the nephew of Colonel Richard Borden. The company was built along the shore of Mount Hope Bay. This spot was perfect because large ships could dock right at the company's door. In the 1840s, the railroad was also extended to the Print Works. It was next to the steamship pier, which had regular service to Providence and New York City. Both the steamships and the railroad were controlled by Colonel Richard Borden, and later by his sons and nephews.

In 1853, Richard Borden, his brother Jefferson, and Oliver Chace bought the nearby Globe Print Works. They renamed it the Bay State Print Works.

For three generations, the Borden family was very powerful. They had control or business interests in the city's banks, the gas company, steamboats, railroads, and mines.

Growing Bigger: The Expansion Years

Fall River did very well during the American Civil War. This put the city in a great position to grow afterwards. By 1868, Fall River had more than 500,000 spindles. This meant it had passed Lowell as the top textile city in the United States. The American Print Works was about to open a new factory in 1867. But then, a terrible fire happened. This was a big problem for the company. They were just finishing up the insurance plans when the fire struck. However, the American Print Works was quickly rebuilt in 1868. It was even bigger and better than before.

A few years later, in 1871 and 1872, Fall River grew very quickly. Fifteen new companies were started, building 22 new mills across the city. Some older mills also got bigger. The city's population grew by an amazing 20,000 people in just these two years. The total mill capacity doubled to over 1,000,000 spindles. Most of these mills made "print cloth." A huge amount of this cloth then went to the American Print Works to be printed.

By 1876, Fall River had one-sixth of all the cotton capacity in New England. It also made half of all the print cloth. "King Cotton" had truly arrived. The city became known as the "Spindle City." It was second in the world only to Manchester, England.

However, the 1870s were a tough time for the textile industry. It started with the Panic of 1873, a financial crisis. The American Print Works failed in 1879. This was partly because of the uninsured losses from the 1867 fire. It was then reorganized as the American Printing Company in 1880.

At its busiest in 1876, the Iron Works employed 600 men. But just a few years later, in 1880, the Iron Works property was divided among its owners. Production of iron stopped soon after. This was because other companies closer to the mines offered more competition.

In 1887, M.C.D. Borden, the son of Col. Richard, took control of the company's shares. He tore down the old Iron Works buildings. Then, he started building several huge new cloth-making mills. These were right next to the American Printing Company. These new mills became known as the "Iron Works Division" of the APC.

Three large warehouses were also built on the lower part of Anawan Street. These stored the many copper printing rollers needed for making print cloth. They also stored customer orders until they were needed. Mill Number 7 was built in 1905 further up on Anawan Street and is still there today. The Narrows Center for the Arts is now in one of the former warehouse buildings.

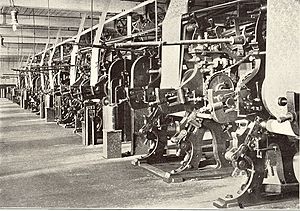

In 1917, the American Printing Company was valued at $2,000,000. The Fall River Iron Works, which was the cloth-making part of the company, had a huge capacity. It had 485,288 ring spindles and 12,702 looms. The print works could print 125,000 pieces of cloth every week.

The Decline of the Mills

The cotton mills of Fall River had mostly focused on making just one product: print cloth. Around 1910, the American Printing Company (APC) was the city's biggest employer. It had 6,000 people working there and was the largest printer of cotton cloth in the world. Many other mills in the city only made print cloth to be printed at the APC. This meant the city's industry relied heavily on one type of product.

By about 1910, the mills in the North also faced tough competition. Mills in the Southern United States had lower labor and shipping costs. Also, the South had invested a lot in new machines and equipment. Many northern mills tried to add more capacity, but it was hard to keep their advantage over the South.

World War I brought a much-needed increase in demand for textiles. Most mills in New England did well during this time. However, the economy slowed down quickly after the war. Production soon made more cloth than people wanted to buy. The price for print cloth dropped sharply. In 1923, Fall River saw the first mills close down.

In 1924, the American Printing Company built a new factory in Kingsport, Tennessee. They started moving much of their production there, following other large northern mills. Thousands of jobs in Fall River were suddenly lost.

The once powerful American Printing Company finally closed its Fall River mills for good in 1934. In 1937, the Firestone Tire & Rubber Company bought their huge factory complex on Water Street. Soon, Firestone employed 2,600 people there. On October 11–12, 1941, just eight weeks before the Attack on Pearl Harbor, a huge fire broke out in the old 1860s mill of the print works. This fire was a major setback for the U.S. war effort. Jesse H. Jones, the Secretary of Commerce, reported that 15,850 tons of rubber were lost in the fire. This was worth about $7,000,000.

In March 1973, another huge fire destroyed the former "Iron Works Division" mills. These mills were going to be used by the Providence Pile Company. But the sprinklers had been turned off during the winter because there was no heat in the buildings.

Today, the site is used by Borden & Remington Chemical Company. This company has roots in the 19th-century textile industry. Several of the late 1800s buildings are still there.

In October 2008, Borden & Remington began tearing down Mill No. 3. It had been empty and was in bad condition. Mill No. 1 was torn down in May 2011. Much of the old Longleaf pine timbers used to build these mills were saved. They have been recycled into new flooring and wood products.

| Roy Wilkins |

| John Lewis |

| Linda Carol Brown |