Great Northern Mine facts for kids

Quick facts for kids Great Northern Mine |

|

|---|---|

Great Northern Mine, 2011

|

|

| Location | Off Jacks Road, Herberton, Tablelands Region, Queensland, Australia |

| Design period | 1870s - 1890s (late 19th century) |

| Built | 1880 - 1940s |

| Official name: Great Northern Mine (Herberton) | |

| Type | state heritage (archaeological, built) |

| Designated | 21 October 1992 |

| Reference no. | 600542 |

| Significant period | 1880s-1940s (fabric) 1880- 1893, 1902-1940s (historical) |

| Significant components | mine - open cut, wall/s - retaining, shed/s, machinery/plant/equipment - mining/mineral processing, adit, headframe, objects (movable) - mining/mineral processing, residential accommodation - housing, shaft, alluvial workings, mullock heap |

| Lua error in Module:Location_map at line 420: attempt to index field 'wikibase' (a nil value). | |

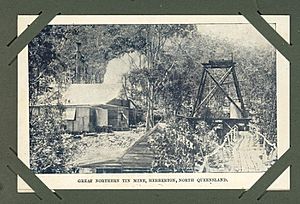

The Great Northern Mine is a special historical mining site. It is located off Jacks Road in Herberton, Queensland, Australia. This mine was active from 1880 to the 1940s. It was added to the Queensland Heritage Register on October 21, 1992, because of its important history.

Contents

Discovering Tin at Great Northern

Imagine, way back in 1879, a rich vein of tin was found at the Great Northern site. Four explorers, William Jack, William Ronald Joss, John Newell, and Thomas Brandon, had been searching in the area. On April 12, 1880, they officially claimed a sixty-acre piece of land.

The Great Northern tin vein was on the eastern side of the Wild River. They followed this three-foot-wide vein for two miles up the ridges. They found a lot of rich tin. Local stories say they even melted some tin right there in a tree stump, using their felt hats to fan the flames!

Jack and Newell told John Moffat about their discovery. Moffat was a well-known mining investor. He agreed to help them build a crushing machine and a smelter in the new Herberton area. By August 1880, about 70 miners were already working in Herberton.

Early Days of the Mine

On September 18, 1880, the Great Northern Mine officially opened. John Moffat and his partners arrived in Herberton in mid-October 1880. Moffat had a lot of experience with milling. He helped choose the best spots for the tin crushing machines. Local miners were excited about his technical knowledge. They knew it was important for the area's development.

Moffat's team started building the foundations for their Great Northern crushing machine in November 1880. After some early attempts at smelting by other miners failed, Moffat got their support for his project. Moffat's machinery arrived in Herberton in February 1881. The Great Northern had a powerful machine with ten heavy stamps to crush the rock. It had its first test run in early May 1881.

Moffat created the Herberton Tin Company to manage the Great Northern crushing machine. This company also looked after all his other mining interests, including the Great Northern Mine.

Success and Challenges

In the 1880s, the Great Northern Mine brought in a steady income for Moffat's company. Up until 1885, the mine was incredibly profitable. The rock they dug up averaged a phenomenal 30% pure tin!

Moffat's manager, William Bonar, was very skilled. He understood how the tin veins ran underground. This helped him decide where to dig next. This was different from other mines in Herberton that often dug recklessly. Bonar worked on two main tin veins, called the Gully and the Eastern. In 1885, they reinforced these two shafts with timber. They also got a new rock drilling machine in 1887. The amount of tin found in the rock (called the assay) dropped in 1885. But at 8.6%, the Great Northern was still very profitable.

Moffat tried to sell the Great Northern Mine and its crushing machine several times in the late 1880s and early 1890s. However, the manager, Bonar, and a local investor, John Newell, did not want outside companies to take over. The mine closed down in 1893, except for some work done by "tributers." These were miners who worked for a share of what they found.

Herberton and the Great Northern Mine faced several problems. Miners sometimes opened too many veins too quickly. It was also hard to get permission to install new machinery. People also expected the Great Northern to always be super rich. There were also problems with tin ore being stolen and tests (assays) being tampered with, even up to World War I.

Later Years and Production

The Great Northern Mine was very important to John Moffat's companies for many decades. Over 30 years, it produced over 4,400 long tons of tin. This tin was worth a huge amount of money back then, about A£220,000. The crushing machine stopped working for a while in 1895.

Moffat managed to get new investors for the Great Northern in 1901. But the crushing machine and mine stayed idle until 1902. The main shaft was dug deeper, down to 213 meters, in the next four years. In the following years, the amount of tin found was only 3.5%. This meant the mine was much less successful than in its first fifteen years. There were also arguments about how to manage the three main shafts: Froghole, Gully, and Great Northern. A lot of water also entered the Gully shaft.

Digging deeper was put on hold until a new headframe could be built in 1909. However, the crushing machine, which was more modern than others, was a great help for miners. Still, the problems with assays and theft continued.

A new structure called a brace was built in 1909 on the New Gully shaft. The mine started working again in mid-1916. They pumped out water down to 91 meters. The winding machinery was fixed, and everything was checked. In 1917, seventeen men were working in the mine. They got 30.5 long tons of tin ore. This produced about five tons of pure tin, worth A£1,016. The company expected its crushing machine to be ready in 1918.

The Gully shaft was cleaned out in 1918. They found a rich amount of ore about 12 meters down. The company was able to pay off its debts. The town's crushing machine started working in February 1918. That year, the Great Northern was the second-highest producer in the area.

In 1928, they found encouraging results from a new area at the 122-meter level. In 1930, the company lost its manager, S. Day, who had been there since 1917. They got A£7,658 worth of tin from 767 long tons of ore, averaging 11.1% tin. The mine's ownership was fully returned to the company. Operations were stopped at the end of the year because the price of tin was very low.

In 1937, they explored the northern parts of the mine. They also repaired old mining areas. They found 29 long tons of wolfram and 81 long tons of tin. In 1938, they dug a new shaft near the boiler shed and found 10 long tons of good ore. In 1940, a new shaft was dug 15 meters deep on the eastern tin vein. They also treated 215 long tons of old waste material, getting 2.6 long tons of tin concentrates.

In 1945, several tons of old waste were treated, but they only got a small amount of metal. No underground mining was done. In 1947, no underground work happened, but some surface searching was carried out. In 1940, J. Newell pumped water out of the "A" shaft. The Great Northern Freehold Mine and its crushing machine changed owners in 1953. The new owner, F. L. Stamp, started work in June. He dug six new holes to find new tin veins. The mine rarely operated after that.

What the Mine Looks Like Today

The Great Northern Mine site shows many parts of historical tin mining in the Herberton area. This includes areas where they dug for tin in riverbeds, dug shafts, and used machinery to lift things and pump water. There are also places for maintenance and living.

There are four main areas:

- Alluvial Workings: These are areas where miners looked for tin in the dirt and gravel of a permanent stream. You can still see stone and concrete walls, and signs of old work areas and camp sites. People say this is where tin was first found in the stream.

- Eastern Shaft: This area is very well preserved. It includes a timber-lined shaft and a timber structure called a headframe. A headframe is a tall frame over a mine shaft used for lowering and raising equipment and miners. There's also a timber and weatherboard shed. Inside this shed, you can find old machinery like an air receiver, compressor, steam engines, winding engine, boiler, and pump. A large pile of waste rock, called a mullock dump, is also nearby.

- Gully Shaft: This shaft is in the middle of the property. It has a main shaft with a collapsed opening and a recently fallen timber headframe. Nearby buildings include a workshop and a blacksmith's shop (now collapsed), a break room, and another timber and weatherboard shed. This shed contains two vertical boilers (used as air receivers), a compressor, a winding engine, and two more boilers. Some of this machinery is believed to have come from another mine.

- House: There is an old two-room house made of timber and iron. It sits on round timber stumps. Inside, you can still find furniture and other items from the former owner. The house is in poor condition due to termites.

Surviving Machinery

The mine still has several pieces of old machinery, including:

- A Colonial boiler from Smith & Faulkner, Brisbane.

- A Tandem air compressor from A.Harkness & Co. Victoria Foundry Bendigo, made in 1891.

- Another Tandem air compressor from J.Horwood & Sons Bendigo Ironworks, established in 1856.

- A Portable steam engine from Marshall & Sons & Co., England, distributed by David Munro & Co. Melbourne.

- A Vertical Special steam pump from Tangye Makers, Birmingham.

- A Colonial boiler in a brick mount from Walkers Limited.

- Another Colonial boiler with no brand.

- Two-cylinder winding engines from Walkers Ltd Engineers Maryborough.

- Two vertical boilers that were used as air receivers.

- A Duplex steam pump (not in its original place).

- A Tandem air compressor from Ingersoll Rand.

Why Great Northern Mine is Important

The Great Northern Mine was added to the Queensland Heritage Register on October 21, 1992. This means it is considered very important to Queensland's history and culture.

Demonstrating History

The Great Northern Mine at Herberton is historically significant because it was the first place in Australia to produce tin from a lode (a vein of ore in rock). Before this, tin was mostly found in riverbeds. The discovery of tin here in 1879 led to the creation of a busy town called Herberton. Within four years, there were 160 other tin mines working nearby. So, the Great Northern Mine played a key role in starting the mining industry and boosting the economy of the Atherton Tableland.

Rare and Unique Features

This mine has the only timber headframe with sheave wheels (the pulleys at the top) still standing in North Queensland. The old machinery that remains here is very rare and complete. It is better preserved than at any other mining site recorded in Queensland.

Some of the rare machines include:

- A Harkness compressor (possibly the only one left in Australia).

- A Horwood compressor (the only known complete one).

- A very old and rare 1878 Marshall portable steam engine, which is in good condition.

It is also very rare to find two tandem steam air compressors, made by two of Victoria's earliest engine builders, still together at an old North Queensland mine. The combination of different mining types—alluvial mining (in riverbeds), hard rock mining (in shafts), and a house—all on one property, is also very rare.

Connection to Important People

The mine is also connected to the famous mining businessman, John Moffat. This was his first big mining project in North Queensland, starting in 1880.

| Lonnie Johnson |

| Granville Woods |

| Lewis Howard Latimer |

| James West |