Haskelite Manufacturing Corporation facts for kids

Quick facts for kids  |

|

| Industry | Manufacturing |

|---|---|

| Fate | Sold off part by part |

| Founded | 1917 |

| Defunct | 1956 |

| Headquarters | Grand Rapids, Michigan |

|

Key people

|

George R. Meyercord James R. Fitzpatrick Emory W. Stoner |

| Products | plywood |

| Revenue | $5,600,000 in 1941 |

|

Number of employees

|

1,000 in 1918 |

Haskelite Manufacturing Corporation (1917–1956) was a group of companies based in Michigan. Their main factory was in Grand Rapids, Michigan. They made a special type of plywood called haskelite. This plywood was used for many different things, like vehicles and buildings.

The company's main office was in Chicago, Illinois. The Grand Rapids factory was much bigger than their first factory in Ludington, Michigan. It could make ten times more plywood each day. At first, this plywood was needed for military airplanes during World War I. Later, it was used in houses, cars, and ships. Haskelite even made the largest plywood panel ever for a US Navy boat. One very famous use for their plywood was in the Spirit of St. Louis, Charles Lindbergh's famous airplane.

Contents

How Haskelite Started

Haskelite Manufacturing Corporation began in late 1917. It was created from the Haskell Manufacturing Company in Ludington. The main reason for starting this new company was to make a lot of haskelite plywood for World War I. The Ludington factory was small, making less than 10,000 square feet of plywood daily. The new Grand Rapids factory was designed to make up to 100,000 square feet per day.

During World War I, Haskelite made airplane bodies for American, British, and French armies. By 1918, they had produced over 5 million square feet of plywood for military planes. The factory was built on 107 acres of land in Grand Rapids. It was close to a busy train station.

To help build the new factory, a temporary company was set up. This company sold stocks and bonds to raise money. The new factory cost $250,000 to build. It was twice the size of the original factory. The factory was located at 1850–1950 Broadway Ave in Grand Rapids.

The main offices for Haskelite were in Chicago. George R. Meyercord, the president, worked there. James R. Fitzpatrick, the sales manager, also had his office in Chicago. Emory W. Stoner, another sales manager, worked in Detroit. In 1941, the company's sales were much higher than before, reaching $5,600,000.

Before 1920, Haskelite plywood was used in buildings, houses, ships, and airplanes. By 1922, over seventy car makers were using Haskelite in their vehicles. The plywood for most of the Spirit of St. Louis was made in Grand Rapids. This was the plane Charles Lindbergh flew non-stop across the Atlantic Ocean in 1927. Haskelite also made plywood parts for the British fighter plane, the de Havilland Mosquito.

The new Haskelite factory was a large, one-story building. It was about 105,000 square feet in size. Construction started in January 1918, even though the ground was frozen. This was because of the urgent need for plywood during the war. New roads were built, and up to 75 teams of horses brought materials to the site every day. The building was finished and ready to use by April, which was very fast.

Special Kinds of Plywood

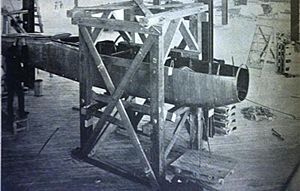

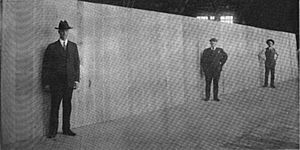

Haskelite Manufacturing Corporation made the largest plywood panels ever. These huge panels were built for a special US Navy boat. This boat was designed to go over 50 miles per hour. The panels were made with layers of mahogany and Spanish cedar wood. They varied in thickness and size. The biggest panel was 88 by 636 inches long.

After 1930, Haskelite developed many different styles of plywood. These were made for specific uses. Some were for boat hulls, doors, refrigerators, street cars, and freight trailers. They even had brand names like KarVarT, Plymetl, Plymold, and Phemaloid.

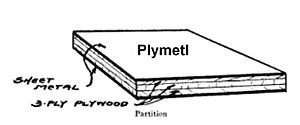

Plymetl

Haskelite made a special plywood called Plymetl. It had extra layers of metal sheets, like steel, aluminum, and copper. Plymetl was used when a strong, lightweight material was needed. It was also very good at resisting impacts. It was used to make storage vaults and in ships, yachts, aircraft, and luxury cars. During World War II, Plymetl from the Grand Rapids factory helped a lot with the war effort. It was used in military vehicles, combat ships, fighter planes, and tanks.

Plymold

Haskelite also helped create a plastic veneer plywood called Plymold. This was also known as duramold plywood. These wood layers were mixed with special plastics for extra strength. They could be shaped into 3D forms, which was great for airplane and ship parts. In 1942, Haskelite added 21,000 square feet to their Grand Rapids building. This was to make more special shaped plywood for WWII military planes and ship interiors. Plymold was also used in railway cars, buses, and automobiles.

Phemaloid

Haskelite Manufacturing Corporation also made a plywood called Phemaloid. It used a special resin that made it fire-resistant. It was also very strong, resisted moisture, and could destroy fungi. This plywood was used for airplane parts and in railroad cars.

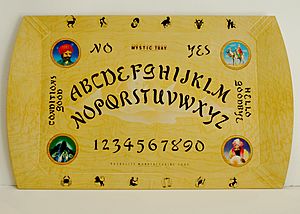

Hasko Trays and Games

Haskelite also made many different serving trays. These trays had designs of flowers, animals, and cartoons. Walter F. Gibian, who led Haskelite's Specialty Division, had the idea for these trays. He wanted to make serving trays that everyone could afford. Before this, serving trays were seen as luxury items. The trays sold much better than expected.

After the trays, Haskelite started making toys under the brand name "Hasko." These included "fortune telling" mystic trays and "talking boards." Some models were the Mystic Tray, the Mystic Egyptian style Board, and the Hasko Mystic Board with zodiac signs. "Hasko" became one of the biggest makers of these "talking boards" in the world. The Hasko Mystic Trays came out in 1942, and the Hasko Mystic Boards in 1944. By 1945, over four million of these mystic items had been sold.

What Happened to Haskelite

In 1949, one of Haskelite Manufacturing Corporation's plants in Grand Rapids was sold. At the end of 1956, the company agreed to sell its other assets to Evans Products Company.