Heat treating facts for kids

Heat treating, also known as heat treatment, is a special way to change how materials work. It's a big part of metallurgy, which is the science of metals. The main idea is simple: you heat a material, hold it at that hot temperature for a while, and then cool it down.

This process makes the material stronger, tougher, or even softer, depending on what you want to achieve. It's mostly used for metals and certain alloys (which are mixtures of metals). Some types of plastics also get heat treated. For ceramics, a similar heating process called sintering is used when they are made.

It's important not to confuse heat treating with hot working. Hot working is when you shape a metal while it's hot, like forging. Heat treating is about changing the material's internal structure, not its shape.

Contents

What is Heat Treating?

Heat treating is a group of processes that involve carefully heating and cooling materials. The goal is to change the material's physical and sometimes chemical properties. Think of it like baking a cake: the heat changes the ingredients into something new with different textures.

Engineers and scientists use heat treating to make materials better for specific jobs. For example, a metal part might need to be very hard to resist wear, or very flexible to bend without breaking. Heat treating helps achieve these different qualities.

Why Do We Heat Treat Materials?

Materials are heat treated for many reasons. One common reason is to make them harder. This is useful for tools that need to cut or scratch other materials, like knife blades or drill bits.

Another reason is to make materials tougher. A tough material can absorb energy without breaking. This is important for things that might get hit or stressed, like car parts or construction beams.

Sometimes, heat treating is used to make a material softer or easier to work with. This can be helpful before shaping a metal, making it less likely to crack during bending or forming. It can also relieve stress inside the material that built up during manufacturing.

How Does Heat Treating Work?

The process usually involves three main steps:

- Heating: The material is slowly heated to a specific temperature. This temperature depends on the material and the desired outcome.

- Soaking: The material is held at that high temperature for a certain amount of time. This allows the heat to spread evenly and for changes to happen inside the material's structure.

- Cooling: The material is then cooled down. The speed of cooling is very important. Cooling quickly can make a material hard, while cooling slowly can make it softer or more flexible. Materials can be cooled in air, oil, water, or other special liquids.

Different combinations of heating temperatures and cooling rates lead to different properties in the final material.

Types of Heat Treatment

There are several common types of heat treatment, each designed for a specific purpose:

- Hardening: This process makes metals, especially steel, very hard. It involves heating the metal to a high temperature and then cooling it rapidly, often in oil or water.

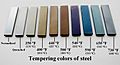

- Tempering: After hardening, metals can be very hard but also brittle (easy to break). Tempering involves reheating the hardened metal to a lower temperature and then cooling it. This reduces brittleness while still keeping much of the hardness.

- Annealing: This makes metals softer and easier to work with. It involves heating the metal to a high temperature and then cooling it very slowly, often by letting it cool down inside the furnace. Annealing also helps remove internal stresses.

- Normalizing: Similar to annealing, normalizing also makes metals tougher and more uniform in structure. It involves heating and then cooling in still air. This process is often used to prepare metal for further treatments.

- Case Hardening: This process makes only the surface of a metal part hard, while keeping the inside softer and tougher. It's useful for parts that need a wear-resistant surface but also need to withstand impacts.

Materials That Are Heat Treated

While metals are the most common materials for heat treatment, other materials also benefit:

- Steel: This is the most common material to be heat treated. Different types of steel can be made incredibly strong, hard, or flexible using these methods.

- Aluminum Alloys: Some aluminum alloys are heat treated to increase their strength and hardness. This is important for lightweight parts in airplanes and cars.

- Plastics: Certain plastics can be heat treated to improve their strength, stiffness, or heat resistance.

- Glass: Glass can be heat treated to make it stronger and more resistant to breaking, like the glass in car windows.

Heat treating is a vital part of making many products we use every day. From the tools in your garage to the parts in your phone, heat treatment helps ensure materials perform their best.

Images for kids

See also

In Spanish: Tratamiento térmico para niños

In Spanish: Tratamiento térmico para niños

| Emma Amos |

| Edward Mitchell Bannister |

| Larry D. Alexander |

| Ernie Barnes |