Hydraulic accumulator facts for kids

A hydraulic accumulator is like a special storage tank for pressure in a hydraulic system. Imagine it as a battery for fluid power! It holds an incompressible liquid, usually oil, under pressure. This pressure comes from an outside source, like an engine, a spring, a heavy weight, or even a compressed gas.

Accumulators help hydraulic systems in a few ways:

- They let the system handle big demands for power without needing a super-strong pump.

- They help the system react quickly when power is suddenly needed.

- They smooth out any jerky movements or changes in pressure.

Think of them as energy storage devices that make hydraulic systems more efficient and responsive. The most common type uses compressed gas, and these are often called hydro-pneumatic accumulators.

Contents

Types of Accumulators

Tower Accumulators

The very first accumulators for hydraulic machines were tall water towers. Water was pumped to a tank at the top of these towers. When the machines needed power, the weight of the water (its hydrostatic head) created the necessary pressure.

These towers were extremely tall and expensive to build. For example, Grimsby Dock Tower, built in 1852, is about 94 meters (309 feet) tall! Because of their size and cost, they were only built for a short time. Newer, smaller designs quickly replaced them.

Some of these old towers still exist today, like the one at Birkenhead, England, and another at Bramley-Moore Dock in Liverpool.

Raised Weight Accumulators

A raised weight accumulator uses a vertical cylinder filled with fluid. A heavy piston sits on top of the fluid, and weights are placed on this piston. The weight pushes down on the piston, which then pushes down on the fluid, creating pressure.

Unlike other types, this kind of accumulator provides a very steady pressure, no matter how much fluid is in the cylinder. The pressure only drops a little as the cylinder empties.

You can see a working example of this type at the hydraulic engine house, Bristol Harbour. This system powered the lock gates until 2010. The famous Tower Bridge in London also used this type of accumulator to open and close its sections. You can still see two of them in the bridge's museum.

Another old example, dating from 1869, is at Limehouse Basin in London. It's a piece of history that shows how hydraulic power was used long ago. London even had a huge public hydraulic power system that worked until the 1970s!

Air-Filled Accumulators

A very simple accumulator can be just an enclosed space filled with air. Sometimes, a vertical section of pipe, made a bit wider, can trap air as the pipes fill with fluid.

These accumulators usually don't store a lot of power because they can't be filled with high-pressure gas. However, they are great for smoothing out sudden changes in pressure. They can make the flow from piston pumps much steadier. They also act like shock absorbers to prevent "water hammer" – a sudden pressure surge that can damage pipes. If the air escapes over time, they need a way to be refilled.

Compressed Gas Accumulators

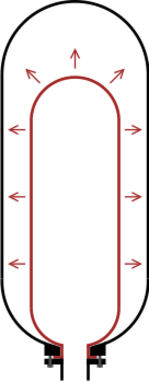

A compressed gas accumulator has two separate sections inside. These sections are divided by something flexible, like a rubber bladder, a diaphragm, or a floating piston. One section holds the hydraulic fluid and connects to the system. The other section contains an inert gas, usually nitrogen, under pressure.

Why nitrogen? Because oxygen and oil can create an explosive mixture when mixed under high pressure. As the fluid enters or leaves the accumulator, the gas gets compressed or expands, which changes the pressure on the fluid.

For systems that use water at low pressure, the water often fills a rubber bladder inside the tank. This stops the water from touching the tank walls, which helps prevent rust. For high-pressure systems, like those in heavy machinery, the gas side is usually pre-charged to a very high pressure. This design protects the bladder or membrane from damage when the system pressure is low.

It's possible to add more gas volume to the accumulator by connecting a gas bottle to the gas side. This can help store more energy without needing a much bigger accumulator.

Spring Type Accumulators

A spring type accumulator works similarly to the compressed gas type. The main difference is that instead of compressed gas, a strong spring (or several springs) provides the force to push on the fluid. As the spring gets compressed, the force it applies to the fluid increases.

Metal Bellows Accumulators

Metal bellows accumulators are like compressed gas types, but they use a sealed, flexible metal bellows instead of a rubber bladder or piston. The fluid can be inside or outside the bellows.

These accumulators have some great advantages:

- They keep the pressure very steady from full to empty.

- They can handle a lot of movement, making good use of their space.

- They can be built to resist very high or low temperatures, or even harsh chemicals.

- They can last a very long time.

However, they are usually much more expensive to make than other types.

How Accumulators Work

In many modern hydraulic systems, especially in vehicles, gas-charged accumulators are preferred. Simpler systems might use spring-loaded ones. A system can even have more than one accumulator.

An accumulator is usually placed close to the pump. A special valve prevents the fluid from flowing back to the pump. If the system uses a piston pump, the accumulator helps smooth out the pulses of energy from the pump. It also helps protect the system from sudden pressure spikes, like water hammer, which can damage pipes and other parts.

Another benefit is that the accumulator can store extra energy when the pump isn't working hard. This means a smaller pump can be used, saving space and cost. For parts that need a lot of fluid quickly, like the landing gear on a large airplane, accumulators can be placed nearby. This helps deliver a huge burst of energy much faster than even a large pump could on its own.

An accumulator can also keep the system pressure steady if there are small leaks, so the pump doesn't have to turn on and off all the time. It also helps absorb pressure changes caused by temperature shifts.

The gas inside a compressed gas accumulator is set to a specific "precharge" pressure. This ensures that the bladder, diaphragm, or piston doesn't hit the ends of the cylinder during operation. If the precharge isn't maintained correctly, the accumulator can get damaged. But if it's designed and cared for properly, an accumulator can work without problems for many years!

See also

- Accumulator (energy)

- Expansion tank

| Sharif Bey |

| Hale Woodruff |

| Richmond Barthé |

| Purvis Young |