Hydraulic press facts for kids

Imagine a super strong machine that can push things with incredible power! That's a hydraulic press. It uses liquid, usually oil, to create a huge pushing force. It works a bit like a mechanical lever, but with liquid instead of solid parts.

This amazing machine was invented by a clever English engineer named Joseph Bramah in 1795. That's why it's sometimes called a Bramah press. Joseph Bramah also worked on things like the flush toilet. He used his knowledge of how liquids move to create this powerful press.

Contents

How It Works: Pascal's Principle

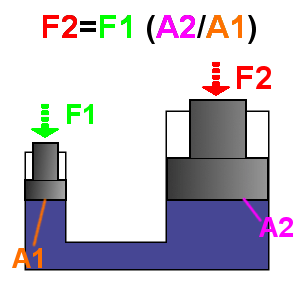

The secret behind a hydraulic press is something called Pascal's principle. It sounds fancy, but it just means that if you push on a liquid in a closed container, the pressure spreads out equally everywhere.

Think of it like this:

- You have a small piston (a kind of plunger) and a big piston.

- You push down on the small piston with a little bit of force.

- This creates pressure in the liquid.

- Because the pressure is the same everywhere, that same pressure pushes up on the much larger big piston.

- Since the big piston has a bigger area, the small push you gave turns into a giant push from the big piston!

You only need small tubes to connect the pump (where you push) to the main press cylinder. These small tubes can easily handle the pressure.

What Hydraulic Presses Are Used For

Hydraulic presses are super useful in many industries. They can do a lot of different jobs because they are so strong and precise.

Making and Shaping Metal

In factories, hydraulic presses are used to:

- Forge metal: This means shaping hot metal by hammering or pressing it.

- Punch holes: They can cut out shapes or make holes in metal sheets.

- Mold things: They press materials into specific shapes using molds.

- Deep drawing: This is like stretching metal into a cup or can shape.

- Form metal: They can bend and shape metal into complex designs.

A hydraulic press can make very detailed shapes. They also use materials efficiently, which saves money. Plus, they take up less space than other types of presses that do the same amount of work.

Other Cool Uses

- Assembling parts: They can push parts together very tightly.

- Taking things apart: They can also help separate tightly fitted components.

- Crushing rocks: In geology, scientists use special hydraulic presses to crush rock samples. This helps them study the rocks and understand things like how volcanism (volcanoes) happens.

See also

- Universal testing machine

- How does a hydraulic press work

| Jewel Prestage |

| Ella Baker |

| Fannie Lou Hamer |