Magnetic separation facts for kids

Magnetic separation is a cool way to separate different things in a mixture using a magnet. It works by pulling out materials that are magnetic from those that are not. This method is super useful for certain minerals that are either ferromagnetic (meaning they are strongly attracted to magnets, like iron, nickel, and cobalt) or paramagnetic (meaning they are weakly attracted to magnets). Most common metals, like gold, silver, and aluminum, are not magnetic.

In magnetic separation, magnets are placed inside special spinning drums that hold liquids. As the drums move, the magnets pull the magnetic particles, creating a concentrated pile of the magnetic material, like a pile of valuable ore.

Contents

How Magnetic Separation Started

Long ago, a scientist named Michael Faraday found out that when you put a substance near a magnet, it changes how strong the magnetic field feels. This discovery helped him realize that different materials could be separated based on how they react to magnets.

Magnetic separation started being used in businesses around the 1860s. Back then, it helped separate iron from brass. After the 1880s, people began using it more to separate strongly magnetic materials. In the 1900s, a new method called "high intensity magnetic separation" came along. This allowed even weakly magnetic materials to be separated.

After World War II, machines using electromagnets (magnets powered by electricity) became very common. They were often used in places where old metal was collected for recycling, called scrap yards. In the late 1970s, magnetic separation got even better with new tools like magnetic pulleys, overhead magnets, and magnetic drums.

In some mines, like those in Cornwall, England, or Tasmania, Australia, magnetic separation was used to separate valuable minerals. For example, a special machine called a Wetherill's Magnetic Separator was used. This machine would take crushed ore and pass it under strong electromagnets. The magnets would pull out the weakly magnetic minerals, like wolframite, leaving the non-magnetic ones behind. These machines were quite powerful, able to process a lot of ore each day.

Where We Use Magnetic Separation

Magnetic separation is used in many places!

- Recycling: You might see huge electromagnetic cranes at recycling centers. They lift and separate magnetic metals from other trash and unwanted stuff. This helps keep materials pure for recycling. Recycling plants often use overhead magnets, magnetic pulleys, and magnetic drums to sort different items.

- Mining: It's very helpful in mining iron because iron is strongly attracted to magnets.

- Food and Medicine: In factories that make food or medicines, magnets are used to remove tiny bits of metal that might accidentally get into the products. This makes sure our food and medicine are safe and clean.

- Pollution Control: This method can also help clean up pollution and is used in chemical factories. It also helps process low-grade ores that don't contain iron.

- Many Industries: Magnetic separation is used in lots of other industries too, like dairy, grain, plastics, oils, and textiles.

Magnetic Cell Separation

Magnetic cell separation is a growing field, especially in medical research. It's being used in studies about cancer and inherited diseases. Scientists use tiny magnetic beads that can attach to specific cells. This helps them separate and study these cells. This technology has led to big discoveries in understanding how cells work, which helps create new treatments for diseases.

Magnetic Separation in Tiny Worlds

Magnetic separation is also used in microbiology, which is the study of tiny living things like bacteria. Here, special molecules or antibodies are used to grab onto specific organisms, DNA, or other tiny parts. This helps scientists find and identify different types of bacteria or genes. When combined with a technique called PCR (which makes many copies of DNA), magnetic separation can give even more accurate results.

Gentle Magnetic Separation

Low-field magnetic separation is often used to clean water and separate complex mixtures. This method uses very weak magnetic fields. It can help remove tiny magnetic particles from water, making it cleaner.

You might even have a type of magnetic separation in your home! Some heating systems have magnetic filters on their pipes. These filters catch tiny bits of rust (which is magnetic) from the water circulating in the system. This stops the rust from building up and making your heating less efficient. The strong magnet in the filter attracts all these tiny metal pieces, keeping your pipes and boiler clean.

Weak Magnetic Separation

Weak magnetic separation is used in recycling to create cleaner iron products. These products have very few impurities and a lot of iron, making them good for reuse. This technique is often used with steelmaking waste to recover valuable materials.

Tools for Magnetic Separation

Today, there are many different tools to perform magnetic separation. These include:

- Grates and plate magnets: Flat magnets that catch metal as materials pass over them.

- Magnet housing and basic cartridges: Enclosed magnets that collect metal.

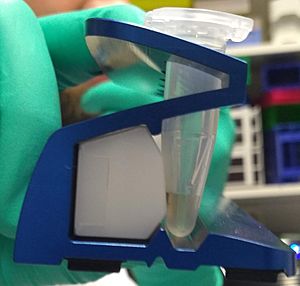

- Pulleys and drums: Rotating parts with magnets inside that separate materials on conveyor belts.

- Self-cleaning separators: Machines that automatically remove the collected magnetic material.

These tools are designed to separate metals using gravity, air pressure (pneumatic systems), or magnetic forces in different ways.

See also

In Spanish: Separación magnética para niños

In Spanish: Separación magnética para niños

| Precious Adams |

| Lauren Anderson |

| Janet Collins |