Man engine facts for kids

A man engine was a clever machine used in mines to help miners travel deep underground. It had moving ladders and fixed platforms that helped miners go up and down the mine shafts. This invention came from Germany in the 1800s. It became very important in the Cornish tin and copper mines until the early 1900s.

Contents

How a Man Engine Works

In Cornwall, these machines were powered by large waterwheels or the mine's steam engines. These engines moved a long series of wooden beams, called "rods," that stretched all the way to the bottom of the mine shaft. These rods moved up and down in a steady rhythm, typically about three to five meters (12 to 15 feet) with each stroke.

Platforms for Miners

Small foot platforms were attached to these moving rods. These platforms were spaced out at the same distance as the engine's stroke. Fixed platforms, also called "sollars," were built into the walls of the mine shaft. These fixed platforms were placed so they would line up perfectly with the moving platforms at the top and bottom of each stroke.

The moving platforms were often small, about 30 centimeters (12 inches) square. This size encouraged miners to stand in the middle, keeping them safe from the shaft walls. Handholds were always placed directly above the foot platforms for extra safety.

Traveling Up and Down

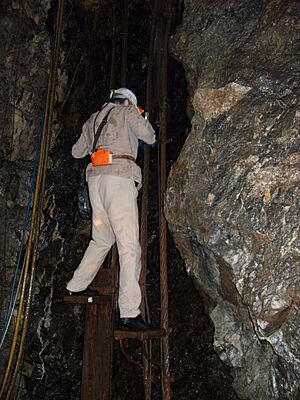

To use the man engine, a miner would step onto a moving platform. This platform would carry them to the next fixed platform. There, the miner would step off and wait. When the rod moved again, the next moving platform would line up, and they would step onto it, repeating the process.

Miners could go up and down at the same time. The pause at each changeover point was long enough (usually two to eight seconds) for two miners to switch places. Some mines, like the Devon Great Consols mine, even had fixed platforms on both sides of the shaft. One side was for miners going down, and the other for those going up.

Keeping it Balanced

Large counterweights were used to balance the heavy rods and the weight of the miners. These were big boxes filled with stones, connected by horizontal beams that worked like a seesaw. This system prevented the full weight from pressing down on the top of the engine. In very deep mines, which could go down more than 640 meters (350 fathoms), extra counterweights were placed in side tunnels at different levels.

Two-Rod System

Sometimes, two rods were used instead of one. In this setup, one rod would be moving up while the other moved down. Miners would step from one rod to the other without waiting on a fixed platform. This made the journey even quicker.

Engine Power

Rotary steam engines were often preferred over beam engines for man engines. Rotary engines had a heavy flywheel that kept the speed steady, creating a predictable pause between each change of direction. Beam engines, which used pistons directly, could sometimes have irregular pauses, which might surprise miners. In Cornwall, only the Wheal Reeth man engine used a piston directly on the rods. A rotary engine also had another benefit: it could power a whim, which is a machine used for lifting materials.

History of the Man Engine

The first man engines appeared in the early 1800s in the silver mines of the Harz mountains in Germany. They were powered by water wheels. However, a similar idea, using buckets to lift people, had been used in Swedish iron mines since the 1600s.

From Pumps to People Movers

The idea for man engines likely came from miners making a simple change to beam pumps. These pumps had long wooden rods that went deep into the mine to remove water. Miners would sometimes stick spikes into these pump rods to hitch a ride up the shaft. Since beam pumps were common in deep mines, it was a natural step to add proper platforms to carry miners safely.

The very first official man engine was installed in 1833 at a mine in Clausthal, Germany. An inspector named Wilhelm Albert and a manager named Georg Dörell attached foot platforms and handholds to the moving pump rods. The 1837 man engine at the Samson Pit in Germany is still there today, though it was updated to use electric power in 1922.

Arrival in Cornwall

The man engine came to Cornwall in January 1842. The Royal Cornwall Polytechnic Society held a competition for the best design, and Michael Loam won. He built a double-rod man engine for the Tresavean Mine near Redruth. Initially, it was powered by a waterwheel.

Later that year, Loam suggested using a steam engine instead of a waterwheel. A powerful steam engine was installed, which made the man engine's stroke longer, from 6 feet to 12 feet. This change greatly improved efficiency. Miners' travel time was cut from about an hour to just twenty-four minutes. This meant they could spend more time working, increasing the mine's output.

By the end of the 1800s, more than a dozen man engines were installed in Cornish mines. Most of these used a single-rod design, which was thought to be safer.

Why They Remained Important

Even when new cable-operated lifts became available, man engines continued to be used. This was especially true in mine shafts that were not perfectly straight. Cable lifts with suspended cages couldn't work well in angled shafts. However, man engine rods could follow these shafts with the help of rollers and special guides.

Economics also played a role. The rods needed for pumping water out of the mine could also be used for the man engine with little extra cost. Even when skips (small carts) or kibbles (large buckets) were used in angled shafts, their tipping motion made them unsafe for carrying people.

Safety of Man Engines

Miners quickly adopted man engines because their pay only started once they reached their workplace underground. Using the man engine saved them a lot of energy. Studies at the time showed that even though man engines had risks, they were generally safer than climbing long ladders. It was less dangerous to be carried up after a tiring shift than to climb a ladder and risk falling due to exhaustion. In some mines, especially in Germany, safety features like wedges or chains were added to limit how far the rod could drop if it broke.

The Levant Mine Accident

On October 20, 1919, a tragic accident happened on the man engine at the Levant Mine in Cornwall. More than 100 miners were being lifted to the surface when a metal bracket at the top of the rod broke. The heavy wooden timbers crashed down the shaft, taking the side platforms with them. Sadly, 31 men lost their lives in this accident. A safety device meant to catch the rod if it fell failed because it was out of alignment after the breakage. The man engine was never replaced, and the deepest parts of the mine were closed.

See also

- Flatrod system

- Belt manlift

- Paternoster lift

| Claudette Colvin |

| Myrlie Evers-Williams |

| Alberta Odell Jones |