Neptune's Staircase facts for kids

Aerial view from the west

|

|

| Waterway | Caledonian Canal |

|---|---|

| Maintained by | Scottish Canals |

| Operation | Hydraulic |

| First built | 1811 |

| Length | 180 feet (55 m) |

| Width | 40 feet (12 m) |

| Fall | 64 feet (20 m) |

| Staircase of 8 locks | |

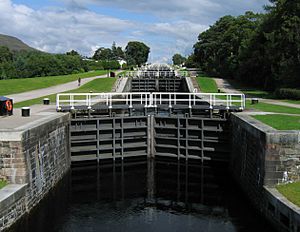

Neptune's Staircase is a special kind of staircase lock system. It has eight locks that work together on the Caledonian Canal in Scotland. This amazing structure was built by a famous engineer named Thomas Telford between 1803 and 1822. It's the longest staircase lock in all of Britain!

Originally, people had to operate the locks by hand. But now, it uses powerful hydraulic systems, making it much easier and faster to use.

Contents

What is Neptune's Staircase?

Neptune's Staircase is located in a place called Banavie, which is close to Fort William. It's just north of Loch Linnhe. The locks are looked after by Scottish Canals.

This staircase lock is the longest in Britain. It lifts boats an impressive 64 feet (20 m) (about 19.5 meters) up or down. It has eight separate locks, and each one is 180 feet (55 m) (about 55 meters) long and 40 feet (12 m) (about 12 meters) wide. It takes boats about 90 minutes to travel through the whole system.

How the Locks Work Today

The big gates on the locks are very heavy, weighing about 22 tons each! It takes a team of at least three lock-keepers to operate the staircase. They try to be efficient, meaning they usually fill each lock with boats going up, or empty them with boats going down. Sometimes, they even let a boat going down pass a boat going up at the same time.

Before machines took over, people had to use large wooden poles called capstans to open and close the gates. It took a lot of effort and many turns of these capstans to move a boat through. Now, with hydraulic power and push-button controls, the journey is much quicker. You can still see the bases where the old capstans used to be.

History of Neptune's Staircase

The idea for the Caledonian Canal came from engineer Thomas Telford. The government asked him to find ways to help people in the Scottish Highlands. He suggested building big projects like the canal to create jobs and help local industries like fishing and farming.

Building the Canal and Locks

In 1803, a special law was passed to start building the canal. Thomas Telford was the main engineer. At first, they planned smaller locks, but then they decided to make them bigger. This was so larger ships, like those trading with the Baltic, could use the canal.

They decided to group many locks together at Banavie to save money. Instead of drawbridges that might hit ship masts, they used strong cast-iron swing bridges. Both the road and railway at the bottom of the locks cross these types of bridges.

To get the stones for the locks, a quarry was opened nearby. By 1809, three of the locks were finished, and the last two were ready by the end of 1811. The whole canal wasn't fully open until October 1822. Once it was open, more and more boats started using it. An inn was even built in 1824 for passengers on the steamboats.

Challenges and Repairs

The canal had some problems early on. In 1829, it had to close for two weeks to fix issues at the Banavie locks. Over the years, there were reports about the quality of the masonry (the stone work) in the locks. Repairs were needed in 1880 and 1910 because of serious defects.

After the First World War, the canal was struggling financially. In 1920, the government gave money for major repairs to the Banavie locks. The canal closed for nine weeks for this work. In 1929, a fishing boat accidentally broke through two lock gates, causing flooding and another three-month closure.

Modern Restoration

In 1962, the canal came under the care of the British Waterways Board. They started a project to mechanize all the locks, finishing by 1969.

By the 1990s, the canal was in trouble again. The lock walls were bulging and leaking. It would have cost a huge amount of money to rebuild them completely. So, engineers came up with a clever plan that cost much less.

For ten winters, from 1995 to 2005, sections of the canal were drained. Workers drilled thousands of holes into the double-layered walls. Then, they used strong stainless steel rods to "stitch" the walls together. They also used huge amounts of grout (a special kind of cement) to seal and waterproof the structures. New lock gates were installed, and new stone blocks were cut for repairs instead of using concrete. By the end of this big project, the locks were probably in better shape than when they were first built!

Images for kids

-

Looking down the locks to the entrance canal from Loch Linnhe and the sea

| William M. Jackson |

| Juan E. Gilbert |

| Neil deGrasse Tyson |