Norton Goldfield facts for kids

Quick facts for kids Norton Goldfield |

|

|---|---|

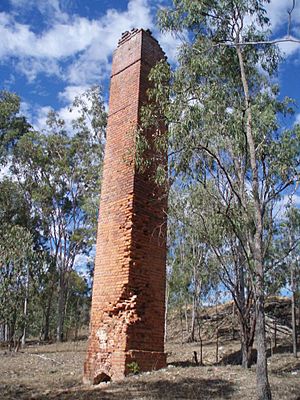

Stamper battery on the Norton Goldfield

|

|

| Location | Norton Road, near Nagoorin, Boyne Valley, Gladstone Region, Queensland, Australia |

| Design period | 1870s - 1890s (late 19th century) |

| Built | 1870s - 1941 |

| Official name: Norton Goldfield, Milton Goldfield | |

| Type | state heritage (archaeological, built) |

| Designated | 27 October 2006 |

| Reference no. | 602491 |

| Significant period | 1870s-1940s (fabric, historical) |

| Significant components | water race, battery/crusher/stamper/jaw breaker, chimney/chimney stack, adit, furnace, footings, shaft, embankment - tramway, flue, tank - water |

| Lua error in Module:Location_map at line 420: attempt to index field 'wikibase' (a nil value). | |

The Norton Goldfield is a historic mining area in Queensland, Australia. It is located on Norton Road, close to Nagoorin in the Boyne Valley. This site was active from the 1870s until 1941. It is also known as Milton Goldfield and is now protected as a heritage site.

Contents

Discovering Gold at Norton

Early Gold Finds and Development

The land where Norton Goldfield is located was once part of a large farm called Milton. This farm belonged to William Henry Walsh. In 1871, two men, George Williams and Charles Lett, found gold there.

The area officially became a goldfield on May 12, 1879. It covered a large space, stretching from the Many Peaks Range to the Boyne River. The goldfield was named after Albert Norton. He was an important local leader at the time.

By 1878-1879, about 60 miners were working at Norton. They used two "three-head stamper batteries." These machines crushed rocks to get the gold out. A miner named Carmichael set up these early batteries. He worked on the goldfield for many years.

Where Gold Was Found

Most of the gold at Norton came from "reefs." These are veins of gold-bearing rock found underground. Some gold was also found as "alluvial gold." This type of gold is found in riverbeds and gullies. It was washed there by water.

Many gold reefs were found both north and south of Norton Creek. Some famous reefs included Advance, All Nations, and Old Welcome. Miners also found silver at Norton.

Challenges of Gold Mining

Dealing with Complex Ores

The rocks at Norton contained many different minerals. Besides gold, they had silver, lead, copper, and zinc. This made it hard to get just the gold out. Miners tried many different ways to separate the gold from these other minerals.

In 1884, a company called Frampton United tried to build a special plant. This plant would use a process called "chlorination" to get the gold. But the next year, the local creek dried up. This stopped their crushing operations.

Roasting and Chlorination Attempts

By 1886, Frampton United built five "reverberatory furnaces." These furnaces heated the ore. They worked with a chlorination plant. This setup could process about 60 tons of ore each week.

Miners did not like working with the hot furnaces. So, workers from the Pacific Islands, sometimes called "Kanaka" laborers, were hired. The furnaces likely "roasted" the ore. This means they heated it to make it easier to process. The ore was crushed first, then roasted. This chlorination plant closed in 1891. Perhaps the ore changed, making the process no longer work well.

Other attempts to process the ore also failed. In 1888, new crushers were installed but did not work. In 1889, the Advance Company built another roasting and chlorination plant. But after trying to treat 70 tons of ore, they gave up in 1890. The problem was likely too much calcite in the ore.

Later Efforts and Final Years

The Conran Gold Mining Company took over in 1891. But their chlorination works also shut down suddenly. By 1893, very little mining was happening.

Carmichael tried chlorination again in 1895, but it failed. In 1899, he built a "water-jacket blast furnace." This furnace was meant to melt the ore. But it did not work well, possibly because no expert was hired to manage it.

Mining picked up a little after 1902. A new road to Bororen made it easier to transport ore. In 1906, Carmichael built another blast furnace. This one was designed to remove lead and zinc. Between 1906 and 1918, small groups of miners worked the area. They sent their ore to Port Kembla for treatment.

During this time, a German engineer named Johan Gundolf built a water-powered crushing mill. It was called an "arrastra." He also built a 375-meter long "water-race." This was a channel that carried water from Norton Creek to power his mill.

In 1918, the Frampton Mine was still active. It employed four men. A 10-head stamper battery was set up in 1923. In 1924, "tramlines" were built. These connected the mine to the battery. This made it easier to move the ore.

The last gold from Norton Goldfield was reported in 1941. The Frampton mine reopened briefly. Its ore was sent to Chillagoe for treatment.

Overall, about 8,776 ounces of gold were mined at Norton Goldfield. This happened between 1879 and 1941.

What Remains Today

You can find the Norton Goldfield by taking Norton Road from Nagoorin. It's about 12 kilometers northeast.

Old Furnace Sites

At the gold roasting furnace site, you can see four long brick bases. They are about 22 meters long. These were likely the bases for the roasting furnaces. They had arched roofs that have now collapsed.

These furnaces were connected to two chimneys by brick and stone channels. One chimney still stands about 10 meters tall. Below the furnaces, there is a brick-paved area. You can also see bases for water tanks and machinery there. Near the creek, there are bases that might have held a water pump.

Another furnace is located about 45 meters to the east. It is about 16 meters long. These five furnaces are believed to be the "reverberatory" furnaces built in 1886.

Water-Race and Stamper Battery

Along Norton Creek, you can see the remains of a 375-yard long "water-race." This channel was used to carry water. It was likely connected to the arrastra (water-powered mill). Parts of the water-race still show brick linings.

About 80 meters from the creek, there is a 10-head stamper battery. It has a steel frame. Next to it, you can see a concrete base where an engine once stood. There are also posts from a collapsed gantry. This gantry was part of a "tramway." The tramway linked the mine to the battery. It helped move the ore.

You might also see small piles of bricks. These could be the remains of other old buildings. There is also a concrete-lined brick tank. It is buried deep in the hillside. This tank might have stored water for the battery.

Why Norton Goldfield is Important

A Look into Queensland's Mining Past

The Norton Goldfield is important for understanding Queensland's history. It shows how mining and settlement developed from the late 1870s to the 1940s. The site's story of success, failure, and finally being abandoned is linked to how hard it was to process the ore.

Unique Mining Methods

The gold roasting works at Norton are quite unusual. You don't find similar setups at other known gold mining sites in southern and central Queensland. Also, the way the battery and the mine worked together is rare.

Learning from the Past

The site offers important clues about old mining technology. It shows the different ways people tried to process difficult ores. Studying these remains can help us learn more about Queensland's mining history and the science of metallurgy (how metals are extracted).

| Anna J. Cooper |

| Mary McLeod Bethune |

| Lillie Mae Bradford |