Pin tumbler lock facts for kids

The pin tumbler lock, also known as the Yale lock, is a common type of lock. It uses small metal pieces called pins. These pins are different lengths and stop the lock from opening unless you use the correct key.

Pin tumbler locks are most often found in cylinder locks. You might also see them in special round locks called tubular pin tumbler locks.

Contents

How Locks Began

The very first known lock like this was found in ancient Iraq. It was part of a palace built around 721–705 BC. But the basic idea of pin tumbler locks might go back even further, to about 2000 BC in Egypt.

These old Egyptian locks were made of wood. They had a wooden post on the door and a sliding bolt. The bolt had holes with pins inside. A special key could lift these pins to the right height. This allowed the bolt to move and unlock the door. These wooden locks were a big step forward for homes in ancient Egypt.

However, these early locks had a weakness. If you lifted all the pins too high, the lock could still open. In 1805, an American doctor named Abraham O. Stansbury created a better pin tumbler lock. His design made it so that lifting the pins too much or too little would stop the lock from opening.

Later, in 1848, Linus Yale Sr. invented a more modern pin-tumbler lock. Then, in 1861, his son, Linus Yale Jr., improved on his father's design. He created the smaller, flat key with jagged edges we see today. He also made the pins inside the lock different lengths. This is the same design used in most pin-tumbler locks now.

How a Pin Tumbler Lock Works

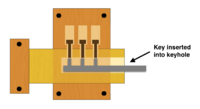

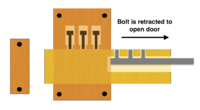

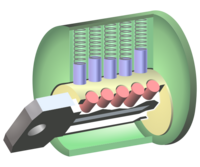

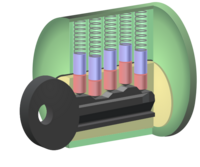

Pin tumbler locks are usually found inside a cylinder lock. This means the lock has an outer case with a round hole. Inside this hole is a part called the plug. To open the lock, this plug needs to spin.

The plug has a slot called the keyway where you put the key. The other end of the plug might have a part that moves the lock's bolt. The keyway often has small edges that stop the pins from falling out. These edges also make the lock harder to pick.

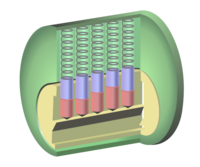

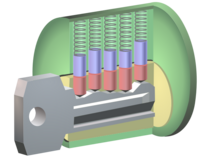

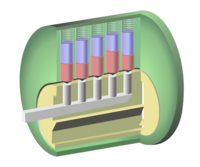

Inside the plug, there are several vertical holes, usually five or six. These holes hold key pins of different lengths. The tops of these pins are rounded so the key can slide over them easily.

Above each key pin is a driver pin. These driver pins are pushed down by small springs. In simple locks, there's one driver pin for each key pin. But some locks, like those used with a master key, might have extra driver pins called spacer pins.

The outer casing of the lock also has vertical shafts that hold these spring-loaded pins.

When the plug and outer casing are put together, the springs push the pins down into the plug. The line where the plug and cylinder meet is called the shear point.

When you put the correct key into the lock, the key's cuts lift the key pins and driver pins to just the right height. This makes a clear line at the shear point. When the pins are aligned at this line, the plug can rotate, and the lock opens. If the key is not in the lock, or if it's the wrong key, the pins block the shear point, stopping the plug from turning.

Types of Cylinder Locks

Pin tumbler locks are often built into a cylinder. This cylinder can be easily removed by a locksmith to change the lock's key. One main benefit of a cylinder lock is that you can change the cylinder without changing the rest of the door's locking parts. Removing the cylinder usually just means loosening a screw and sliding it out.

Another benefit is that you can get cylinders from different companies that all use the same type of key. This means you can have many different types of locks—like nightlatches, deadbolts, and roller door locks—all opened by the same key or a master key system.

Some common types of cylinder locks include:

- Rim-mounted (also called night latch) cylinders

- Euro cylinders

- Key-in-knobset cylinders

- American and Scandinavian round mortise cylinders

- Scandinavian oval cylinders

There are also standard shapes for lock cylinders that come in different lengths to fit different door thicknesses. These shapes include the europrofile, the British oval profile, and the Swiss profile.

Other Kinds of Pin Tumbler Locks

A tubular pin tumbler lock is a pin-tumbler lock that has a round keyhole.

A dimple lock is a pin tumbler lock where the key's special cuts are on the side of the key, not on the top edge.

Master Key Systems

A master-keyed lock is a special pin tumbler lock. It can be opened by two or more different keys. These locks are often used in buildings with many offices, hotels, or student housing.

Each person gets a change key that only opens their own door. But there's also a master key. This key can open all the doors. The building manager usually keeps the master key so they can enter any room.

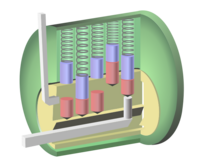

In a master-keyed lock, some or all of the pin holes have three pins instead of two. Between the driver pin and the key pin, there's a third pin called a spacer pin (or master wafer). This creates two shear points in each pin line. One shear point is where the driver and spacer pins meet. The other is where the spacer and key pins meet.

The lock is made so that one set of shear points works with the individual change key. The second set of shear points is the same in all the locks and works with the master key. A small problem with these locks is that they can sometimes be easier to pick. This is because having more shear points gives a lock picker more chances to succeed.

More complex master-key systems exist too. They can have several levels of master keys. This means some master keys open only certain groups of locks, while a top-level master key opens everything.

Lock Weaknesses

Lock Picking

Basic pin tumbler locks can be opened using several lock picking methods. These include lock bumping and using snap gun tools.

To make locks harder to pick, many high-security cylinders use special pins called security pins. These pins are designed to catch inside the lock cylinder if someone tries to use a snap gun or a bump key. Some types of security pins are spool pins, which look like a cotton spool, and serrated pins, which have small grooves cut into them.

These special pins can make a lock picker think they are making progress when they are not. This adds time and difficulty, which can stop an attacker. However, a very skilled lock picker might still be able to open the lock eventually. Security pins can also make bump attacks less likely to work.

Lock Snapping

Lock snapping is a way to force open certain types of cylinder locks. It involves twisting the lock cylinder very hard, usually with a tool like locking pliers. This breaks the lock mechanism and allows access. It can take less than two minutes to snap a lock and get inside. Police in the UK have said that many doors in the country might be at risk from lock snapping.

Lock snapping happens when the lock has a weak spot where a bolt goes through a thinner part of the lock. Newer locks are designed to prevent this. Some have a front section that breaks off, but leaves enough of the lock behind to stop someone from getting in. Other designs have more than one part that can break off. This stops the door from being opened from the outside, but still allows it to be opened from the inside with a key.

Blowtorch Attacks

Some criminals use a small blowtorch to melt the plastic or composite material around the lock and door handle. They do this to create a hole deep enough to reach the lock's inside parts. The goal is to get past any protective layers of the lock. The weakest point of many euro locks is the screw hole in the middle. This screw holds the lock in place, and above it is the part that locks and unlocks the door. Once they get past the outer layers, they can apply pressure to this screw hole area. This can break the lock, similar to the snapping method.

Protecting Your Locks

To protect against drilling, picking, bumping, snapping, and other attacks, look for cylinders that meet certain safety standards. In the UK, these are Sold Secure SS312 Diamond or TS007 3 Star standards. When you install these stronger cylinder door locks, it's also a good idea to make sure they are used with strong, secure door handles.

See also

- Key relevance

- Magnetic-coded lock

- Wafer tumbler lock