RepRap facts for kids

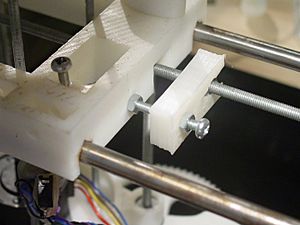

RepRap is a cool project that aims to create a special kind of 3D printer. The name RepRap comes from "replicating rapid prototyper." What makes it special? It can print most of its own parts! This means it can make copies of itself.

Because it's an open design, all the plans and designs for RepRap printers are free for anyone to use and share. They are released under a special license called the GNU General Public License.

The idea behind RepRap is to make it super cheap for anyone to build complex things without needing big factories. Imagine a machine that can make more machines, and those new machines can make even more! This could help people create useful products easily. Studies have even shown that using RepRaps to print everyday items can save money.

The RepRap project started in England in 2005 at the University of Bath. Now, hundreds of people all over the world work together on it.

Contents

How Did RepRap Start?

Dr. Adrian Bowyer, a teacher at the University of Bath, started the RepRap project in 2005. He got money from a group called the Engineering and Physical Sciences Research Council to begin.

Key Moments in RepRap History

- September 13, 2006: The first RepRap prototype, called RepRap 0.2, printed a part that was exactly like one of its own. This was a huge step!

- February 9, 2008: RepRap 1.0, named "Darwin," made more than half of its own plastic parts.

- April 14, 2008: A RepRap made its first useful item for a person: a clamp to hold an iPod in a car.

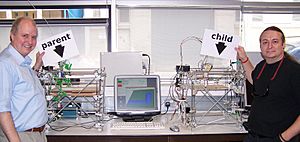

- May 29, 2008: The Darwin RepRap successfully copied all of its own plastic parts. This means it "replicated" itself! A few hours later, the "child" machine made its first part too.

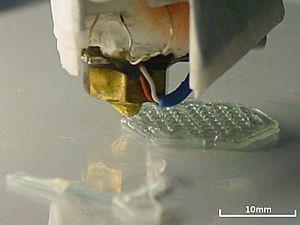

- April 2009: RepRaps learned to print electronic circuit boards. They could print both plastic and special conductive ink.

- October 2, 2009: The second RepRap design, called "Mendel," printed its first part. Mendel looked like a triangle-shaped prism, different from the earlier cube shape.

- August 31, 2010: The third design, "Huxley," was created. It was a smaller version of Mendel.

- 2012: The first successful "Delta" design, called "Rostock," appeared. It had a very different look and used new parts like fishing lines instead of belts.

Sadly, in 2016, a company called RepRapPro in the UK, which was part of the project, stopped selling printers. This was because there were too many other cheap 3D printers on the market. But RepRapPro China is still going strong!

What Parts Make a RepRap?

Since RepRap is an open source project, many different versions have been made. Designers are free to change things and make improvements. The only rule is that they must share their improvements with everyone else.

Some popular RepRap printer designs include:

- Prusa i3

- Hangprinter

- RepRap Fisher

- RepRap Snappy

- RepRap Morgan

- RepRap Ormerod

- RepRap Darwin

- RepRap Mendel

How Does RepRap Use Software?

RepRap isn't just a machine; it's a whole system for making things. This system includes special computer programs.

Designing and Printing with RepRap

- CAD (Computer-Aided Design): This is software for creating 3D models on a computer.

- CAM (Computer-Aided Manufacturing): This software takes your 3D design and turns it into instructions for the RepRap printer.

At first, two main CAM programs were used: "RepRap Host" and "Skeinforge." Both could turn 3D models into "G-code," which is the language the printer understands.

Later, other popular programs like slic3r and Cura were made. There's even a special program called Franklin firmware that lets RepRap printers do other things, like carving or handling liquids.

Many people in the RepRap community like to use free 3D modeling programs such as Blender, OpenSCAD, and FreeCAD. But you can use almost any 3D design program as long as it can save files in formats like STL. This means artists can use tools they already know, even commercial ones like SolidWorks or Tinkercad.

What Materials Can RepRap Print?

RepRaps can print objects using different types of plastic, called thermoplastics. Some common ones are:

- ABS

- Polylactic acid (PLA)

- Nylon

- HDPE

- TPE

The strength of parts printed with RepRap using PLA and ABS is similar to parts made by expensive commercial printers.

Unlike with most commercial machines, RepRap users are encouraged to try new materials and methods. They then share their findings with everyone. This has led to new ways of printing unusual materials, like ceramics!

Recycling Plastic for Printing

People have also designed special machines called "RecycleBots." These machines can turn waste plastic, like old shampoo bottles or milk jugs, into new plastic "filament" that RepRaps can use. This is good for the environment and can help create "fair trade filament" by using local waste. Printing products where they are needed also helps the environment.

Printing Electronics

A big goal for the RepRap project is to print its own electronic circuit boards. Imagine a printer that can print its own "brain"! Here are some ideas people are working on:

- Low-melting metals: Using special metal alloys that melt easily to add circuits inside a plastic part as it's being printed.

- Conductive plastics: Using plastics mixed with silver or carbon that can carry electricity.

- Directly printing solder: Solder is what connects electronic parts.

- Laying wires: Putting thin wires into the part as it prints.

Some RepRap machines can even be used with a MIG welder to print metal parts, like steel! The RepRap idea can also be used for carving machines or laser welding.

How Are RepRaps Built?

The main goal is for RepRaps to eventually build almost all of their own mechanical parts. However, some parts, like sensors, motors, and tiny computer chips (called microcontrollers), cannot be printed by a 3D printer yet. These parts still need to be made separately.

The plan is to get closer to 100% self-replication with each new version of the RepRap. For example, the team has been trying to find ways to add electrical wires and circuit boards directly into the printed parts. This would allow RepRaps to make more complex items, even things with simple motors. Another part that can't be printed yet are the threaded rods used for movement. Researchers are looking into using special "Sarrus linkages" that can be printed to replace them.

Who Works on the RepRap Project?

The main team members who helped create RepRap include:

- Dr. Adrian Bowyer, who started the project.

- Ed Sells, who studied 3D printing and self-replication.

- Vik Olliver, the first volunteer, who suggested using PLA plastic.

- Michael S. Hart, who created Project Gutenberg.

What Are RepRap's Big Goals?

The RepRap project's main goal is to create a machine that can copy itself. But it's not just for fun! The real aim is to give people everywhere a low-cost "desktop manufacturing" system. This means individuals could make many of the things they use every day right at home.

From a science point of view, the project wants to prove that 3D printing can be used to make a "von Neumann universal constructor." This is a fancy way of saying a machine that can build anything, including copies of itself.

RepRap in Education

Many experts believe RepRap technology has a lot of potential for schools and learning. RepRaps have already been used to build robots for education. Some people even say that RepRaps could start a "revolution" in STEM (Science, Technology, Engineering, and Math) education. This is because they make it cheap for students to create things and build affordable scientific equipment using open hardware designs.

See also

In Spanish: Proyecto RepRap para niños

In Spanish: Proyecto RepRap para niños

- Self-replicating machine

- Disruptive technology

- Fab lab

- Fab@Home